Composite materials

A composite material and semi-preg technology, applied in the field of composite materials, can solve problems such as reducing the viscosity and drapability of semi-preg, not recommending semi-preg, and delaying adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

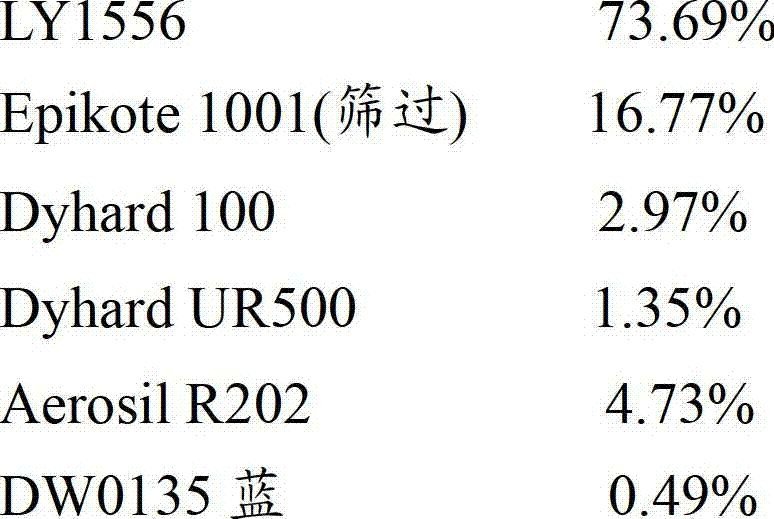

Embodiment 1

[0089]

Embodiment 2

[0091]

Embodiment 3

[0093] Epikote 816MV 95%

[0094] Sylvagel 1000 5%

[0095] The following viscosities were obtained for shear rates when measured using a Bohlin Gemini Rheometer with 40mm parallel plates.

[0096] Table 1

[0097] Shear rate s -1

Example 2 (Pas)

Example 3 (Pas)

0.11

4148

2242

1.05

538

314

10.39

111

46

[0098] 103.11

40

5

[0099] The shear thinning properties of Examples 2 and 3 are clearly shown.

[0100] A backing layer is then applied to one of the outer surfaces (up to 200 g / m2 of material).

[0101] Such assemblies then have the ability to be pressed together without a polyethylene interlayer. This has been measured using the following test method, which presses two plies of material together such that the backing layer acts as the interface between the two plies.

[0102] The backing layer has been shown to distribute itself evenly onto the once adjacent substrate surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com