Chord pipe hot molding method and hot press molding mold used for spud legs of marine oil drilling platform

A drilling platform pile leg and offshore oil technology, which is applied in the field of offshore oil drilling, can solve the problems of workpiece oxidation, slow heating, decarburization, etc., and achieve the effects of reduced oxidation, regular shape, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0021] A thermoforming method for a chord tube used for pile legs of an offshore oil drilling platform, comprising the following steps:

[0022] 1) Carry out blanking of oxygen acetylene according to the size of the chord after forming, and obtain blank A;

[0023] 2) Using IGBT industrial solid state relay intermediate frequency induction heating unit (intermediate frequency induction heater installed vertically) to rapidly heat blank A. The heating temperature is 900°C-950°C, and the heating time is 1.5-2 hours to obtain blank B;

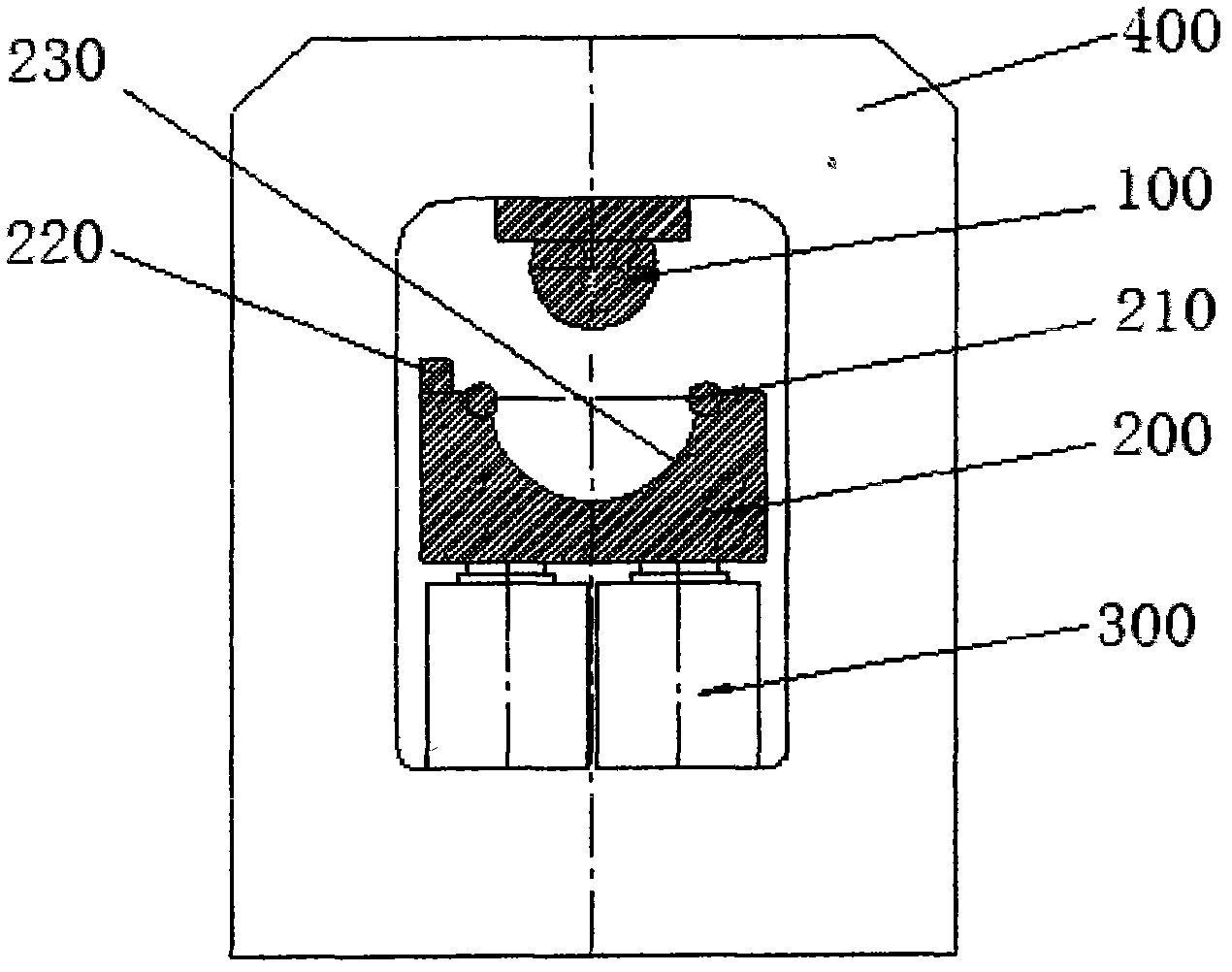

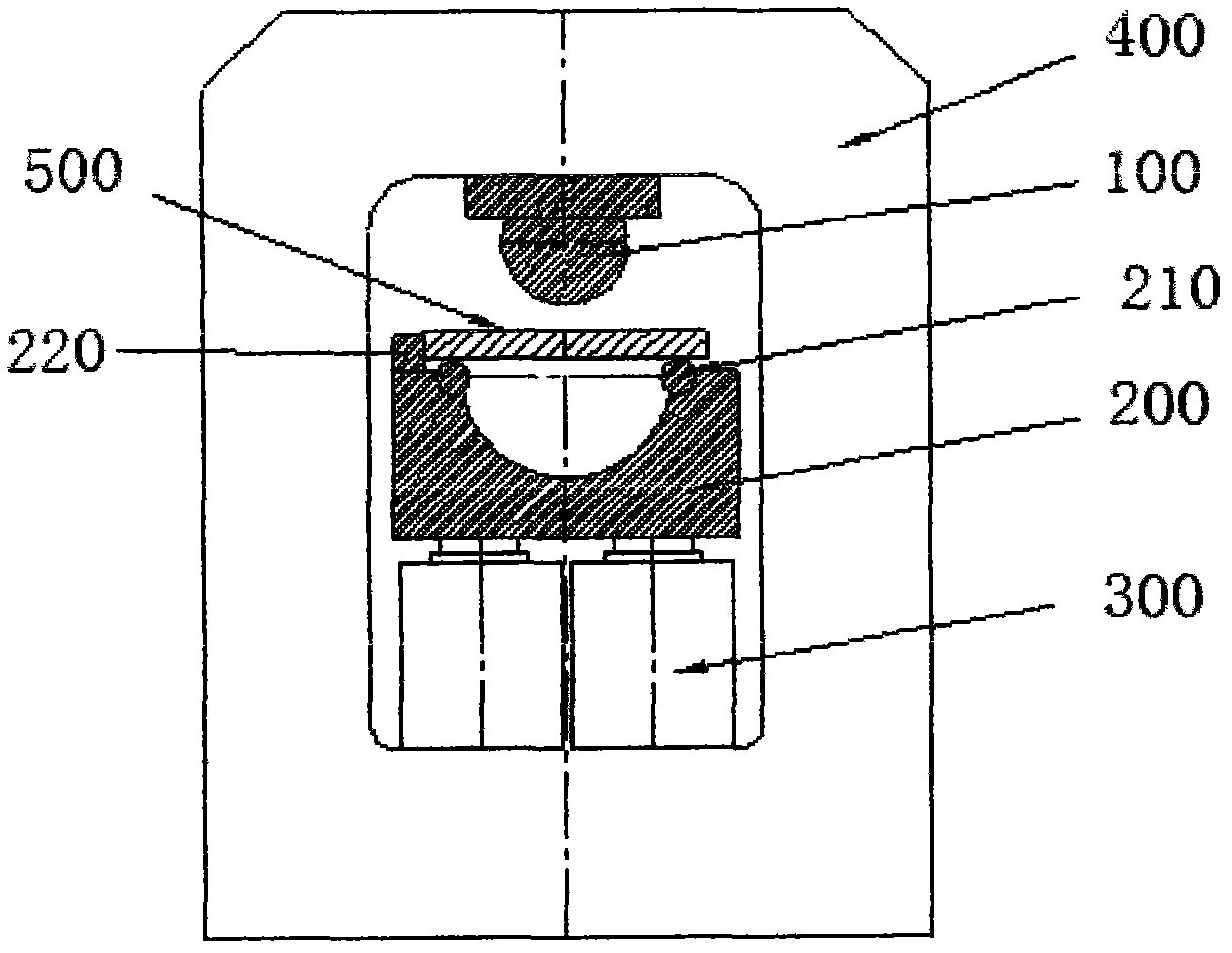

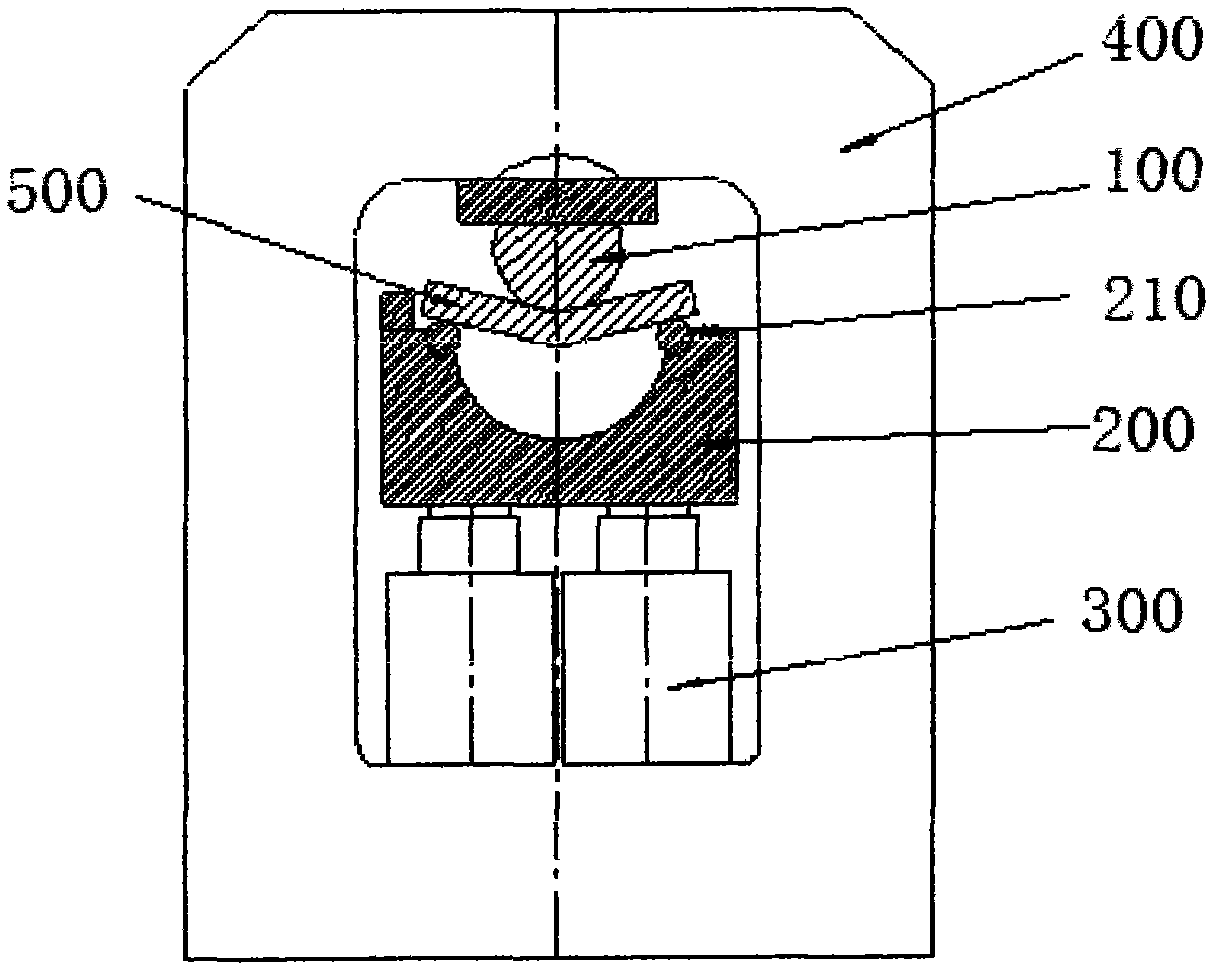

[0024] 3) The large-tonnage portal press is used for hot-press forming. The structure of the large-tonnage portal press is a frame type, and the hydraulic power is below it. For the thermoforming mold of the large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com