Extraction method for reducing emission of chemical oxygen demand (COD) in pure terephthalic acid (PTA) wastewater

An extraction method and wastewater technology, which is applied in extraction water/sewage treatment, natural water treatment, chemical instruments and methods, etc., can solve problems such as hazards, PX removal is rarely mentioned, and the side effects of reverse osmosis membrane swelling affect membrane life. To achieve the effect of COD emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

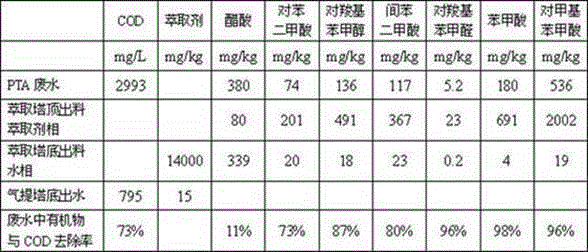

Embodiment 1

[0017] This implementation example includes the following two steps:

[0018] In the first step, the extraction agent n-propyl acetate and PTA waste water are sent to the extraction tower at a mass ratio of 1:4, the waste water flow rate is 2.0t / h, the PTA waste water is added from the bottom, and the extractant is added from the top, and the extraction tower is a packed tower , the efficiency is equivalent to 3-4 theoretical equilibrium stages, the operating temperature of the tower is 38-45°C, and the oil phase from the top of the extraction tower is sent to the PTA dehydration tower;

[0019] In the second step, the water phase discharged from the top of the extraction tower enters from the top of the stripping tower, nitrogen gas is introduced into the bottom of the stripping tower, and the mass ratio of nitrogen to water is 1:16, and the water discharged from the bottom of the stripping tower goes to the sewage treatment station. The gas is sent to the PTA dehydration tow...

Embodiment 2

[0024] With the same raw material in example 1, carry out experiment in the similar mode in example 1, just the extraction agent of the 1st step changes n-butyl acetate into, the 2nd step stripping tower air inlet and the mass ratio of influent change into 1 :20. As a result, the COD of PTA wastewater was reduced from 3050mg / L to 901mg / L, a reduction of 70%; after air stripping, the residual extractant in water was reduced from 6000mg / kg to 13mg / kg.

Embodiment 3

[0026] With the same raw material in example 1, carry out experiment in the similar mode in example 1, just the extraction agent of the 1st step changes isobutyl acetate into, and the mass ratio of the 2nd step air stripper air inlet and influent is changed into 1 :20. As a result, the COD of PTA wastewater was reduced from 3134mg / L to 992mg / L, a reduction of 68%; after air stripping, the residual extractant in water was reduced from 6470mg / kg to 40mg / kg.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap