Method for preparing 1,5-pentadiol by means of selective hydrogenolysis of tetrahydrofurfuryl alcohol

A tetrahydrofurfuryl alcohol, selective technology, applied in the field of selective hydrogenolysis preparation 1, can solve the problems of high price of noble metal Rh, limited catalyst application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

[0021] Preparation of Catalyst by Impregnation Method

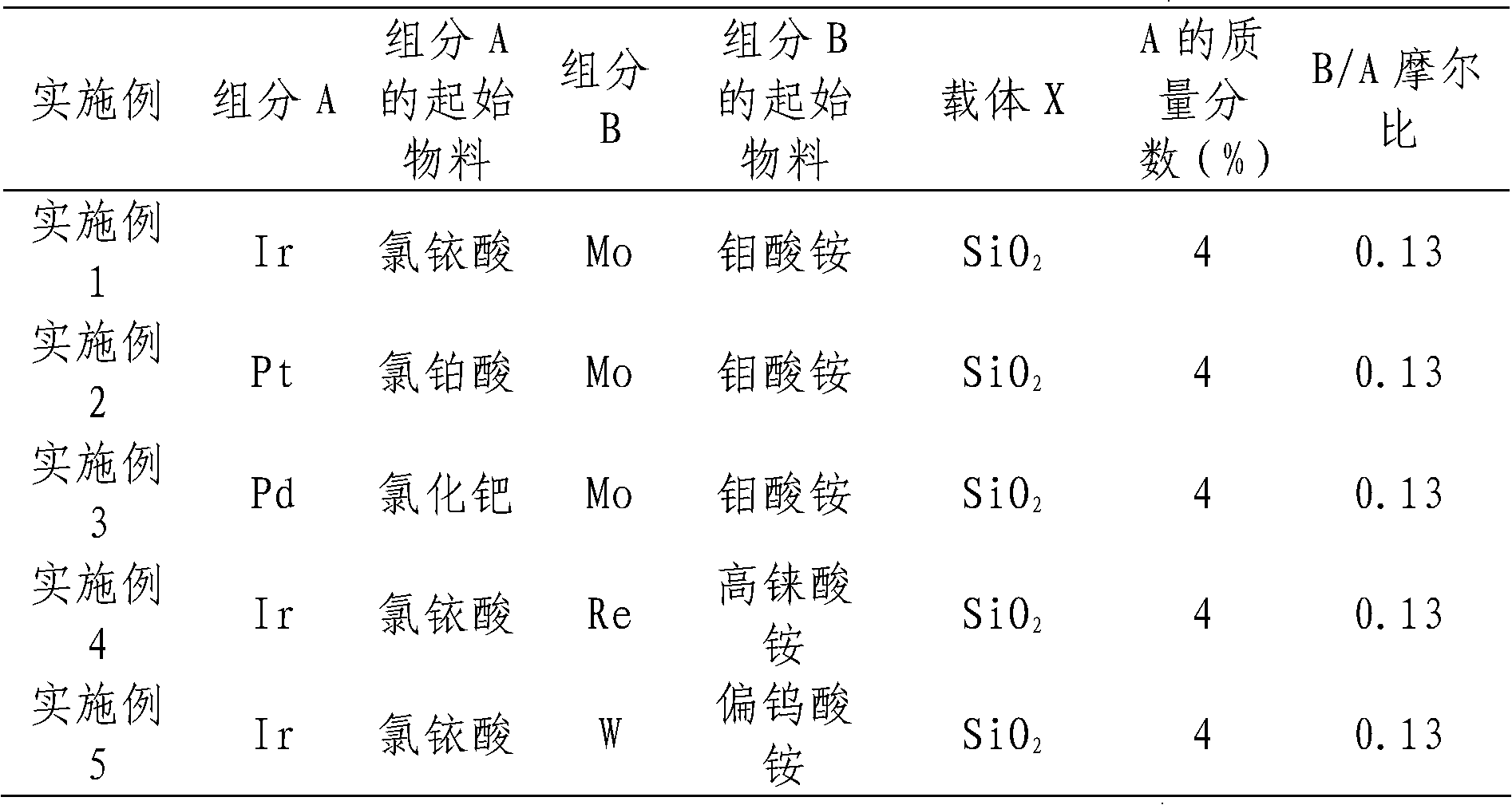

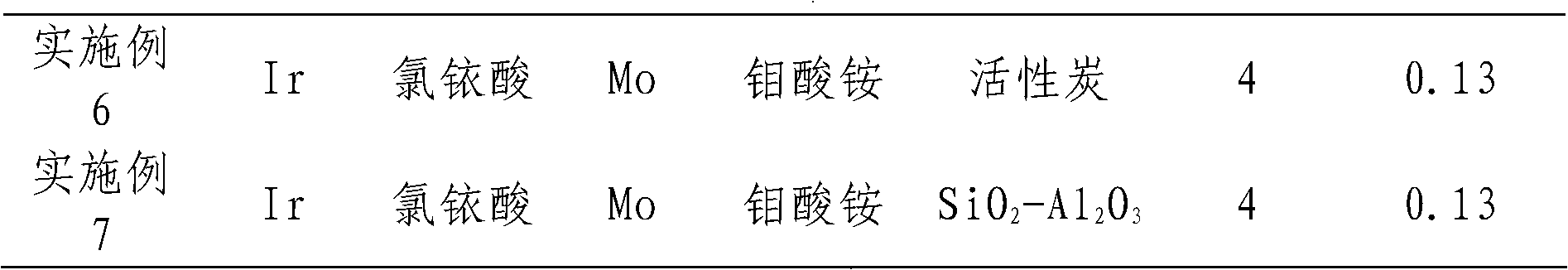

[0022] Add 10% soluble salt solution containing A to the carrier for impregnation according to a certain metering ratio, age at room temperature for 12 hours, and then dry in an oven at 120°C for 12 hours; then weigh the components according to a certain B / A molar ratio The soluble salt solution of B is added to the above-mentioned carrier impregnated with component A, aged at room temperature for 12 hours, then dried at 120°C for 12 hours, and calcined in air at 500°C for 3 hours to obtain the supported type A-B / X catalyst. The composition of catalyst in each embodiment, the kind of starting material of component A, B is shown in Table 1.

[0023] Table 1. Catalyst composition

[0024]

[0025]

Embodiment 8

[0027] Catalyst activity evaluation

[0028] The catalyst evaluation of the present invention is carried out in a fixed-bed mobile phase reactor, which is a stainless steel tube with an outer diameter of 6 mm and a length of 360 mm. The experimental process is as follows: 2g of catalyst is loaded into the reaction tube, the catalyst is reduced in situ before the reaction, the reduction temperature is 200°C, H 2 The pressure is 6MPa, H 2 The flow rate was 160mL / min, and the catalyst was reduced for 2 hours under this condition. After the reduction is completed, it is lowered to the reaction temperature, and the H 2 The flow rate is 60mL / min, the flow rate of tetrahydrofurfuryl alcohol liquid is 0.04mL / min, the pressure is adjusted to the required reaction pressure, and samples are taken for analysis after 6 hours of reaction.

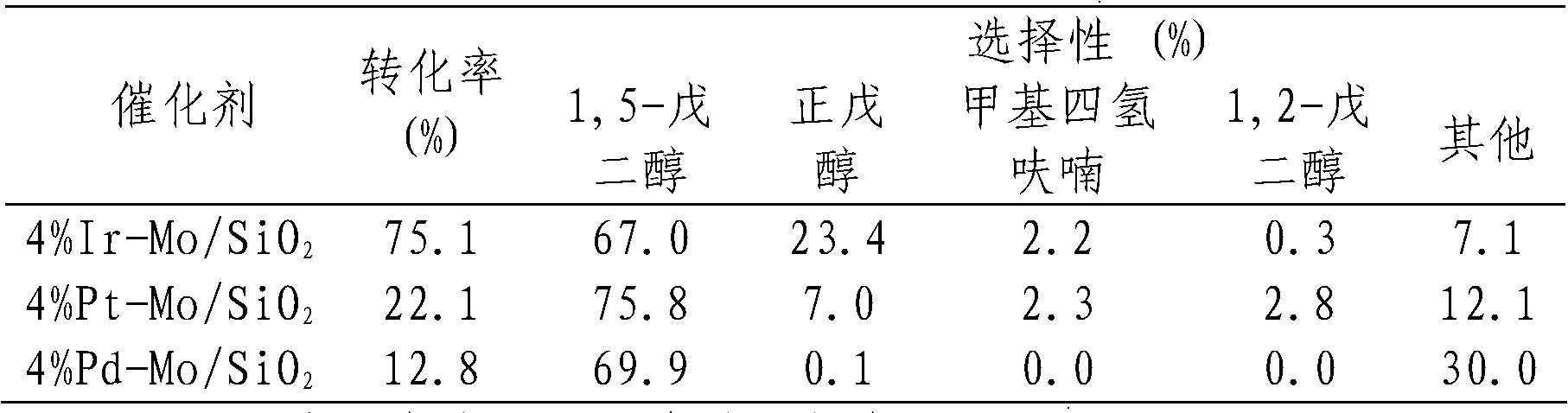

[0029] (1) Comparison of the hydrogenolysis activity of tetrahydrofurfuryl alcohol with different noble metals, the activity evaluation results are s...

Embodiment 12

[0056] Catalyst Stability Test

[0057] For 4%Ir-Mo / SiO 2 (Mo / Ir=0.13) The catalyst was tested for stability, and the results are shown in Table 7.

[0058] Table 7 Catalyst stability test

[0059]

[0060] Note: The reaction pressure is 6MPa, the concentration of tetrahydrofurfuryl alcohol is 20%, and the catalyst used is 4% Ir-Mo / SiO 2 (Mo / Ir=0.13).

[0061] After the catalyst was tested for 24 hours of activity, the conversion rate and selectivity tended to be stable, and with the progress of the reaction, the selectivity of the catalyst to 1,5-pentanediol gradually increased, indicating that the catalyst had good stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com