Method for chemically preparing nano microcrystalline cellulose by utilizing moso bamboo

A technology of nanometer microcrystalline and bamboo fiber, which is applied in the field of pulp and paper engineering, can solve the problems of long growth cycle, insufficient supply of fiber raw materials, high price, etc., and achieve the effect of increasing economic income.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

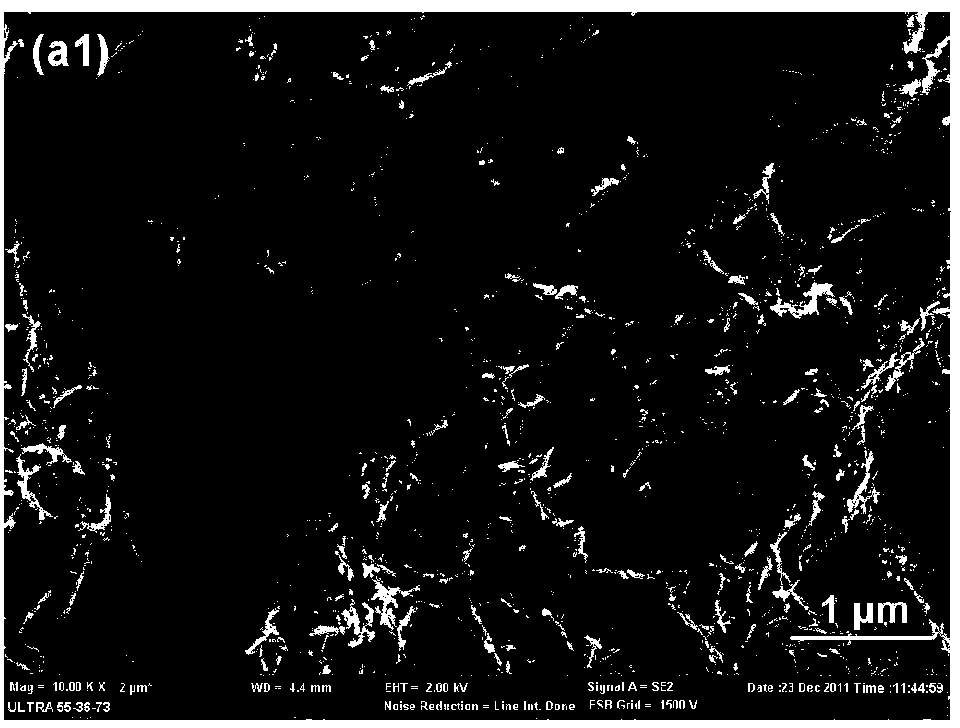

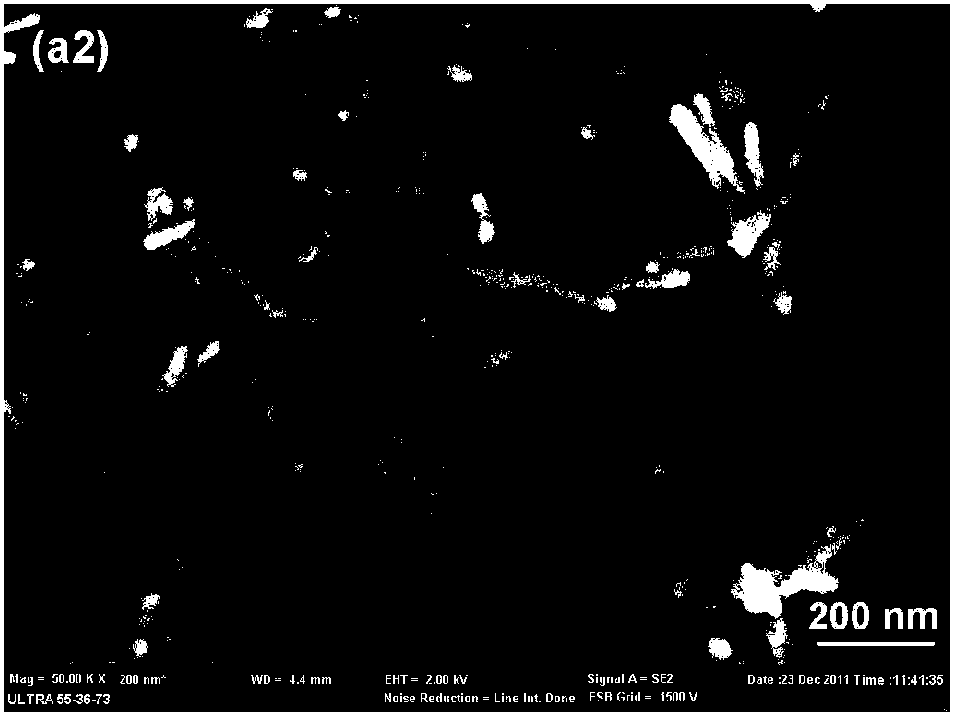

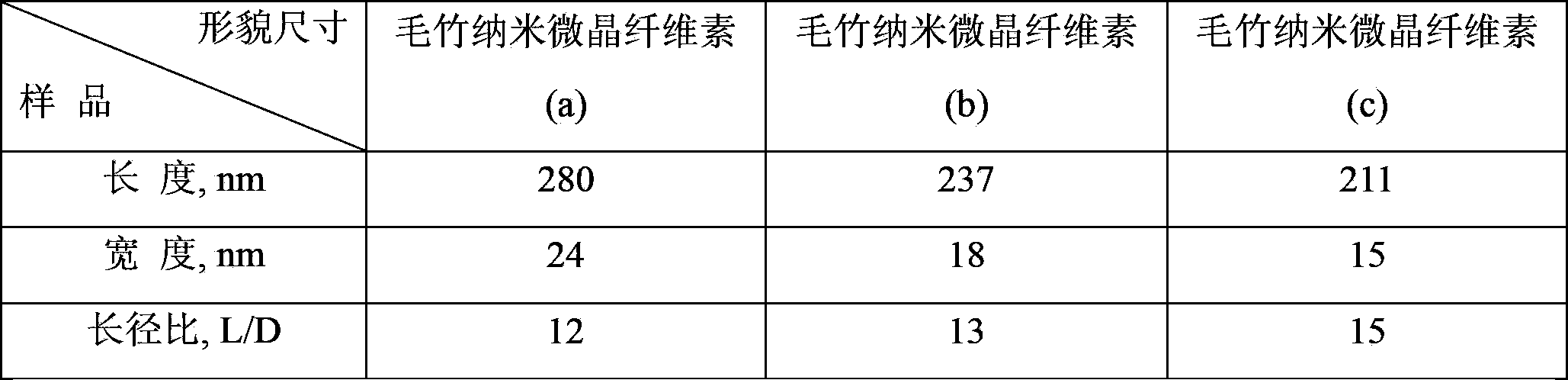

Image

Examples

Embodiment 1

[0021] 1) Deleafing, washing and drying the moso bamboo, crushing it with a plant grinder, and filtering it through a 100-mesh sieve to obtain moso bamboo powder with a particle size less than or equal to 0.15mm;

[0022] 2) Place the moso bamboo powder obtained in step 1) at 80°C with 4.0wt% Mg(OH) under the action of mechanical stirring 2 Reaction in the solution for 100min, moso bamboo powder and Mg(OH) 2 The solution mass ratio is 1:5, repeated 3 times, during which the residual alkali is washed with distilled water to obtain moso bamboo fiber;

[0023] 3) Using 1.5wt%Ca(ClO) 2 Under the action of mechanical stirring, the bamboo fiber obtained in step 2) was bleached at 80°C for 210 minutes, and the bamboo fiber and Ca(ClO) 2 The mass ratio of solution is 1:10, repeats 4 times, washes residual chlorine with distilled water in the meantime, obtains high-purity moso bamboo fiber;

[0024] 4) The high-purity moso bamboo fiber obtained in step 3) was placed in a 30wt% trich...

Embodiment 2

[0027] 1) Deleafing, washing and drying the moso bamboo, crushing it with a plant grinder, and filtering it through a 100-mesh sieve to obtain moso bamboo powder with a particle size less than or equal to 0.15mm;

[0028] 2) Place the moso bamboo powder obtained in step 1) at 90°C with 4.0wt% Mg(OH) under the action of mechanical stirring 2 Reaction in the solution for 90min, moso bamboo powder and Mg(OH) 2 The solution mass ratio is 1:10, repeated 3 times, during which the residual alkali is washed with distilled water to obtain moso bamboo fiber;

[0029] 3) Using 2.0wt%Ca(ClO) 2 Under the action of mechanical stirring, the bamboo fiber obtained in step 2) was bleached at 80°C for 180 minutes, and the bamboo fiber and Ca(ClO) 2 The mass ratio of solution is 1:20, repeats 4 times, washes residual chlorine with distilled water in the meantime, obtains high-purity moso bamboo fiber;

[0030] 4) The high-purity moso bamboo fiber obtained in step 3) was placed in a 50wt% benze...

Embodiment 3

[0033]1) Deleafing, washing and drying the moso bamboo, crushing it with a plant grinder, and filtering it through a 100-mesh sieve to obtain moso bamboo powder with a particle size less than or equal to 0.15mm;

[0034] 2) Place the moso bamboo powder obtained in step 1) at 70°C with 6.0wt% Mg(OH) under the action of mechanical stirring 2 Reaction in the solution for 120min, moso bamboo powder and Mg(OH) 2 The solution mass ratio is 1:10, repeated 3 times, during which the residual alkali is washed with distilled water to obtain moso bamboo fiber;

[0035] 3) Using 3.0wt%Ca(ClO) 2 Under the action of mechanical stirring, the bamboo fiber obtained in step 2) was bleached at 60°C for 150 minutes, and the bamboo fiber and Ca(ClO) 2 The mass ratio of solution is 1:20, repeats 4 times, washes residual chlorine with distilled water in the meantime, obtains high-purity moso bamboo fiber;

[0036] 4) The high-purity moso bamboo fiber obtained in step 3) was reacted in a mixed solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com