Warm-air clothes dryer with horizontal double discharge pipes

A technology for air outlet ducts and clothes dryers, which is applied to household clothes dryers, washing devices, textiles and papermaking, etc. It can solve the problems of extending the drying time by 30 minutes, taking up space and taking 90 minutes, etc. , to achieve the effect of convenient travel and travel, high heat energy utilization rate, and less heat energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the present invention is described and implemented:

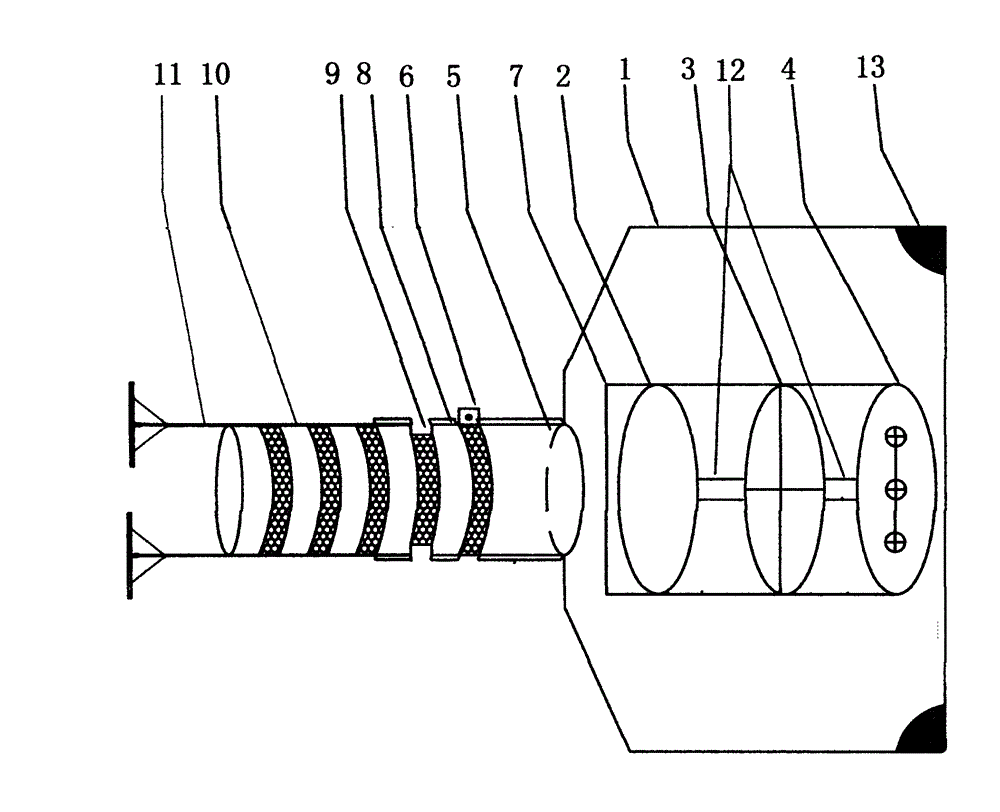

[0025] A warm air clothes dryer with double horizontal air outlet pipes, comprising a body 1, a heating element 2, a blower device 3, a control system 4, two air outlet pipes 5, two air outlet clips 6, and several clothes clips, It is characterized in that: the air outlet clip is installed on the outside of the air outlet pipe, the air outlet pipe is horizontal to the ground and connected to the body, the heating element is installed on one side of the fixing part of the body, the blowing device is installed behind the heating element, and the body There is an air inlet on one side of the body, and the control system is on the other side of the body fixture. The control system has a wire connected to a power switch and a wind speed adjustment button, and the other end of the wire is connected to a heating element and a blower.

[0026] How to do it: Take drying a single...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com