Induced crack structure of frame bridge

A technology for inducing joints and frame bridges, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of poor water-stopping effect of frame joints, increased cumulative deviation of jacking, and more cracks, so as to reduce construction costs. , the structure is simple, the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

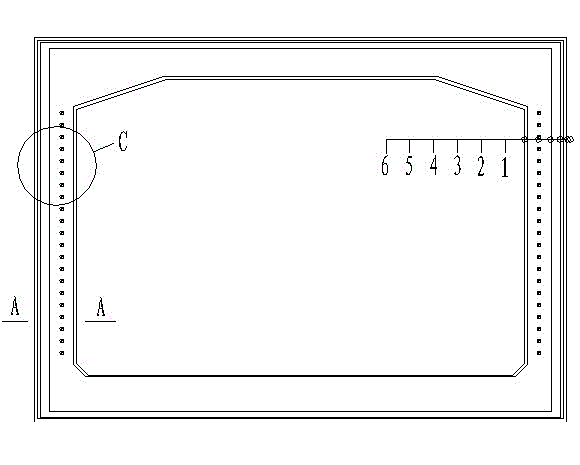

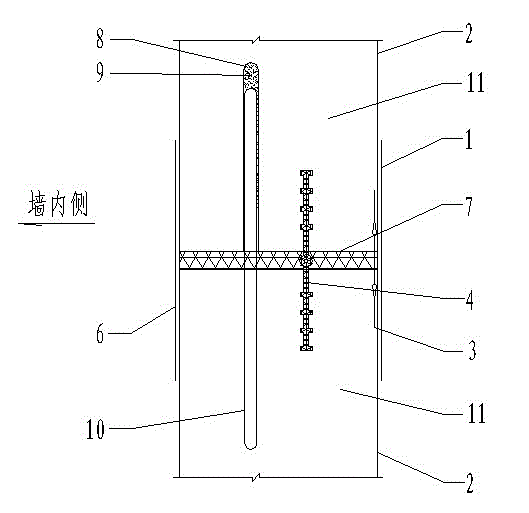

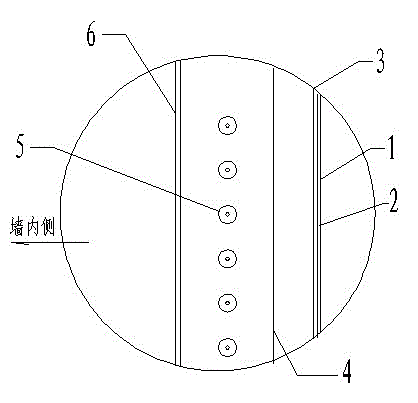

[0022] as attached Figure 1-3 As shown, a frame bridge induced joint structure, the induced joint is arranged in the frame, the caulking plate 7 is arranged in the described induced joint, and the frame height direction is spaced along the frame height direction in the side walls on both sides of the frame at the induced joint. A number of steel shear pins 5 are arranged along the length of the frame. The steel shear pins 5 are composed of an iron sleeve 8 with an inner diameter of 30 mm and a round steel 10 with a diameter of φ28 mm. The round steel 10 passes through the caulking plate 7 and is inserted into the iron sleeve 8, the other end of the iron sleeve 8 is a closed end, which is filled with asphalt ointment 9, and the non-closed end of the iron sleeve 8 is flush with the surface of the caulking plate 7. The induced seam is also embedded with a steel edge waterstop 3 forming a closed loop along the induced joint on the outside of the frame reinforcement, and a rubber ...

Embodiment 2

[0030] as attached Figure 4-6 As shown, this embodiment is basically the same as Embodiment 1, the difference is that no steel edge waterstop and rubber waterstop are provided in this embodiment. It includes induction joints arranged in the frame bridge, and caulking plates 7 are arranged in the induction joints. In the side walls on both sides of the frame at the induction joint, several steel shear pins 5 arranged along the length direction of the frame are arranged at intervals along the height direction of the frame. The round steel 10 is composed of round steel 10, which passes through the caulking plate 7 and is inserted into the iron sleeve 8. The other end of the iron sleeve 8 is a closed end, which is filled with asphalt ointment 9, and the non-closed end of the iron sleeve 8 The end is flush with the surface of caulking plate 7. A polyurethane waterproof coating layer 2 and a chlorinated polyethylene waterproof coiled material layer 1 are sequentially arranged on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com