Environment-friendly type sound absorption barrier

An environmentally friendly and sound-absorbing technology, which is applied in noise-absorbing devices and buildings, can solve the problems of poor corrosion resistance of metal sound-insulating panels, poor sound-absorbing performance of low-frequency noise, and reduced sound-absorbing performance, achieving good sound-absorbing effects , sound-absorbing performance does not decline, the effect of strong drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

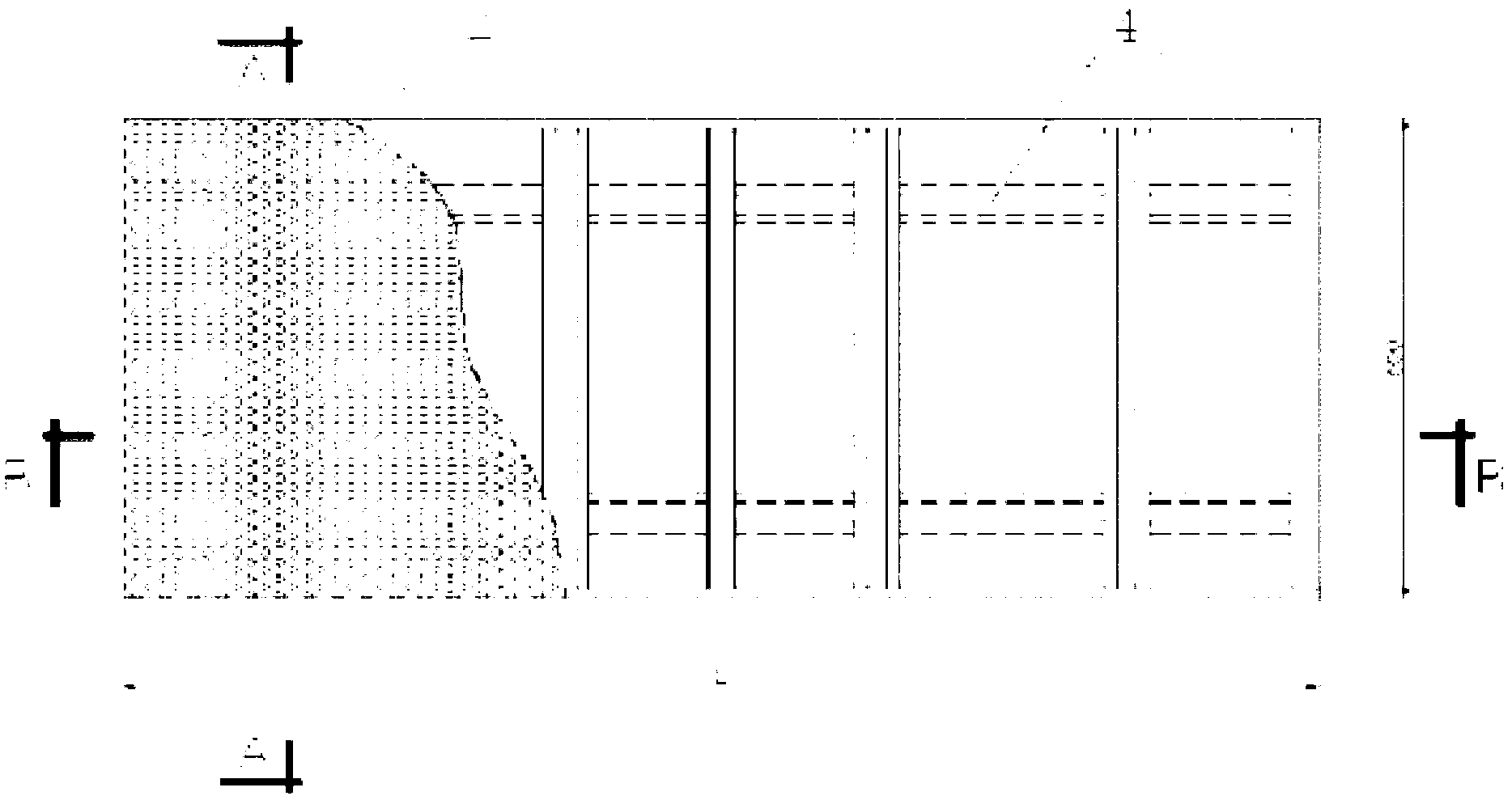

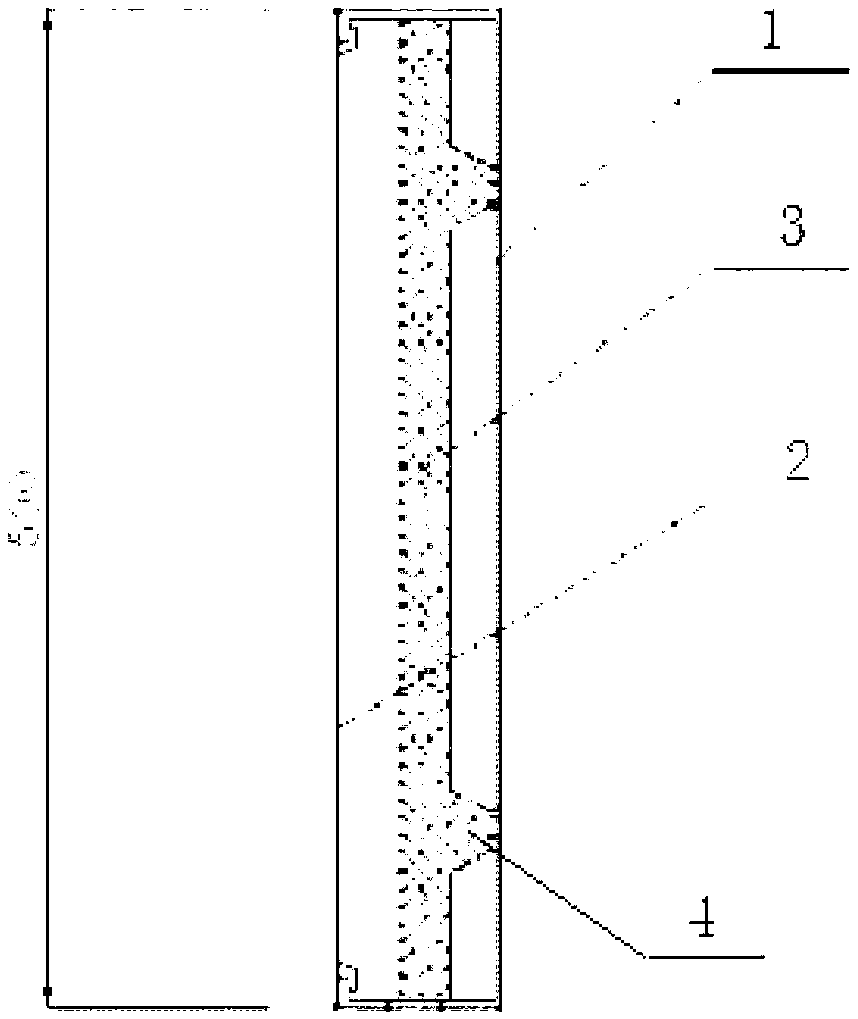

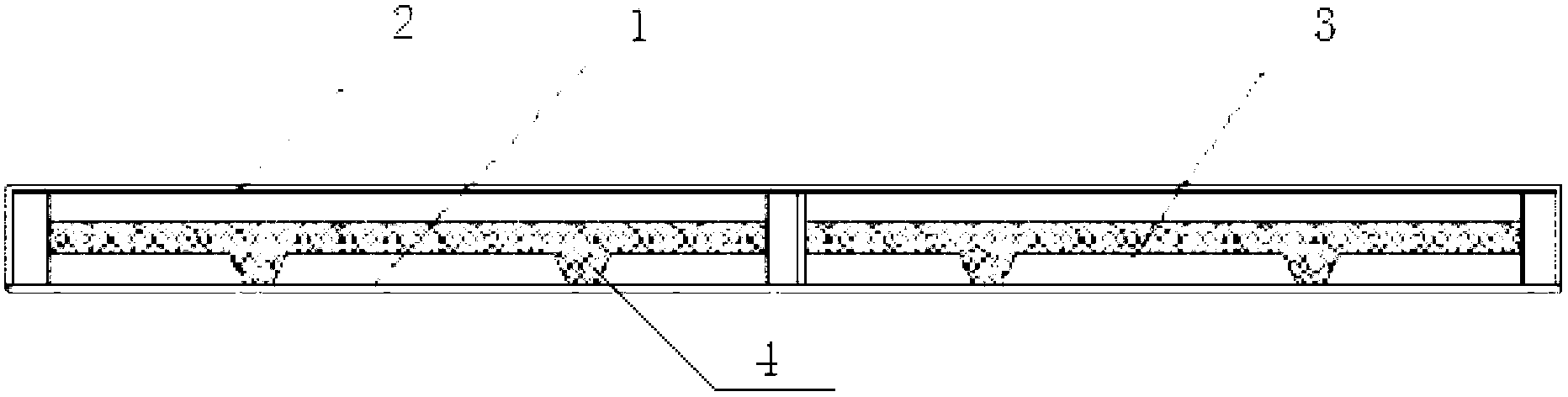

[0026] Such as Figure 1-3 The environment-friendly sound-absorbing barrier shown includes a box body 1, a cover body 2 and a sound-absorbing layer 3, and the cover body 2 is connected to the box body 1 through a slot. The sound-absorbing layer 3 is a double-sided wave structure, the waves on both sides are perpendicular to each other, the wave bottom width is 20mm, the wave height is 40mm, and the thickness of the sound-absorbing layer excluding waves is 10mm. The sound-absorbing layer is arranged in the box body and forms a cavity with the bottom surface of the box body and the cover body. The cover body 2 is a perforated panel, the hole is circular, the hole diameter is 3 mm, and the perforation rate is 20%. Both the box body 1 and the cover body 2 are made of fiberglass with a thickness of 3.5mm, and the sound-absorbing layer 3 is made of polyester fiberboard. The thickness of the environment-friendly sound-absorbing barrier is 100mm.

[0027] According to GB / T20247-200...

Embodiment 2

[0029] Such as Figure 1-3 The environment-friendly sound-absorbing barrier shown includes a box body 1, a cover body 2 and a sound-absorbing layer 3. The cover body 2 is connected to the box body 1 through a slot, and the sound-absorbing layer is arranged in the box body and connected to the bottom surface of the box body and the sound-absorbing layer 3. Cavities are formed between the cover bodies. The thickness of the two cavities are 50mm and 110mm respectively. The sound-absorbing layer 3 is a double-sided wave structure, the waves 4 on both sides are perpendicular to each other, the wave bottom width is 40mm, the wave heights are 50mm and 110mm respectively, and the thickness of the sound-absorbing layer excluding waves is 30mm. The cover body 2 is a perforated panel, the hole is circular, the hole diameter is 5mm, and the perforation rate is 25%. Both the box body 1 and the cover body 2 are made of fiberglass with a thickness of 4.5mm, and the sound-absorbing layer 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Perforation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com