Combined structure system between pulverized coal boiler and side bunker bay of coal-fired power plant

A technology of pulverized coal boiler and combined structure, which is applied in the direction of industrial buildings, etc., can solve the problems of poor stability between coal bunkers, low utilization rate of boiler space, high comprehensive cost of boiler room and coal bunker, etc., so as to improve space utilization and structure Simple and compact, the effect of improving structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

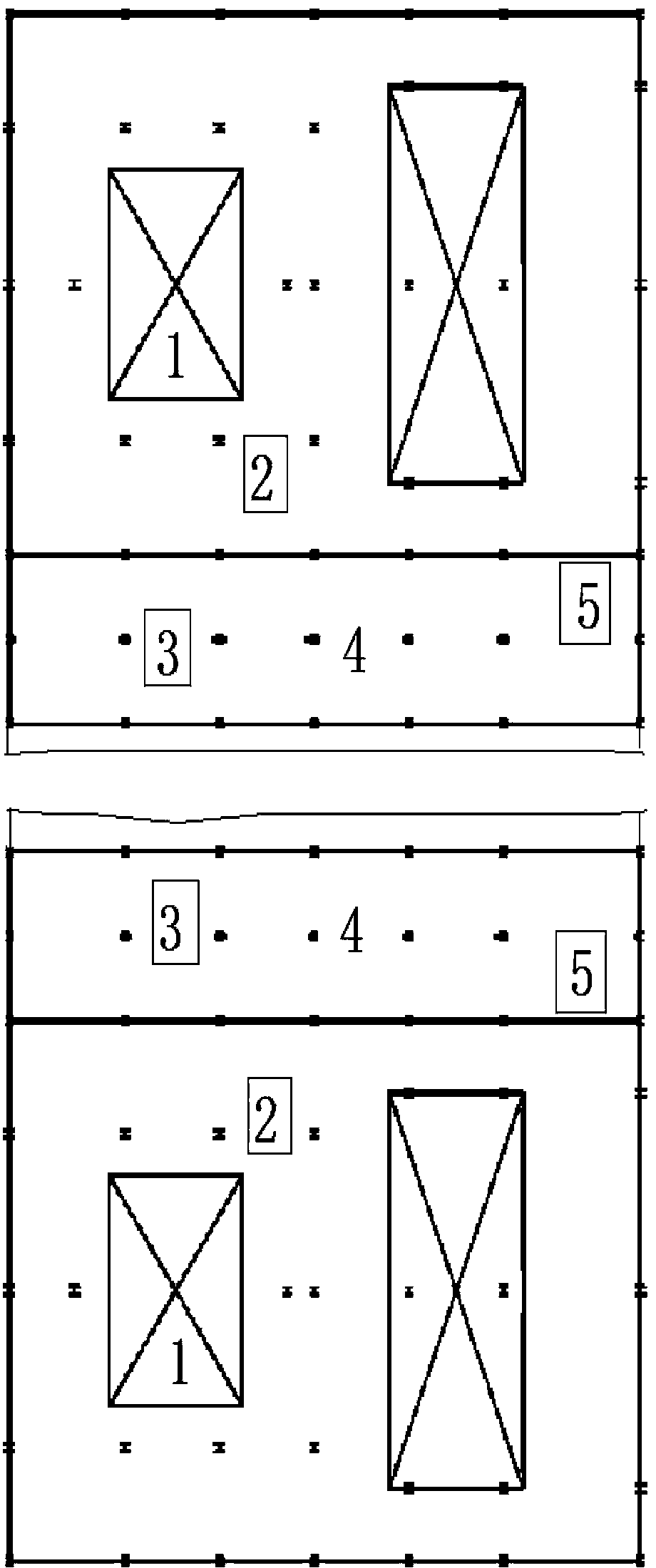

[0019] A joint structure system between pulverized coal boiler and side coal bunker in coal-fired power station, as attached figure 1 As shown, it includes a boiler 1, a coal bunker room 3, and a coal mill 5. The boiler 1 includes a boiler body steel frame 2, the coal bunker room 3 is a steel frame structure 4, and the coal bunker room steel frame 4 is connected to the boiler The main body steel frame 2 is connected, and the coal mill 5 is arranged in the steel frame 4 structure between coal bunkers. There are two boilers 1, and an independent coal bunker 3 and a coal mill 5 corresponding to each boiler are arranged between the two boilers, and the boiler body steel frame 2 of each boiler and its corresponding coal bunker Steel frame 4 connections. The steel frames of the two boilers are not connected to each other. The boiler 1 is type and tower type power station pulverized coal boiler.

Embodiment 2

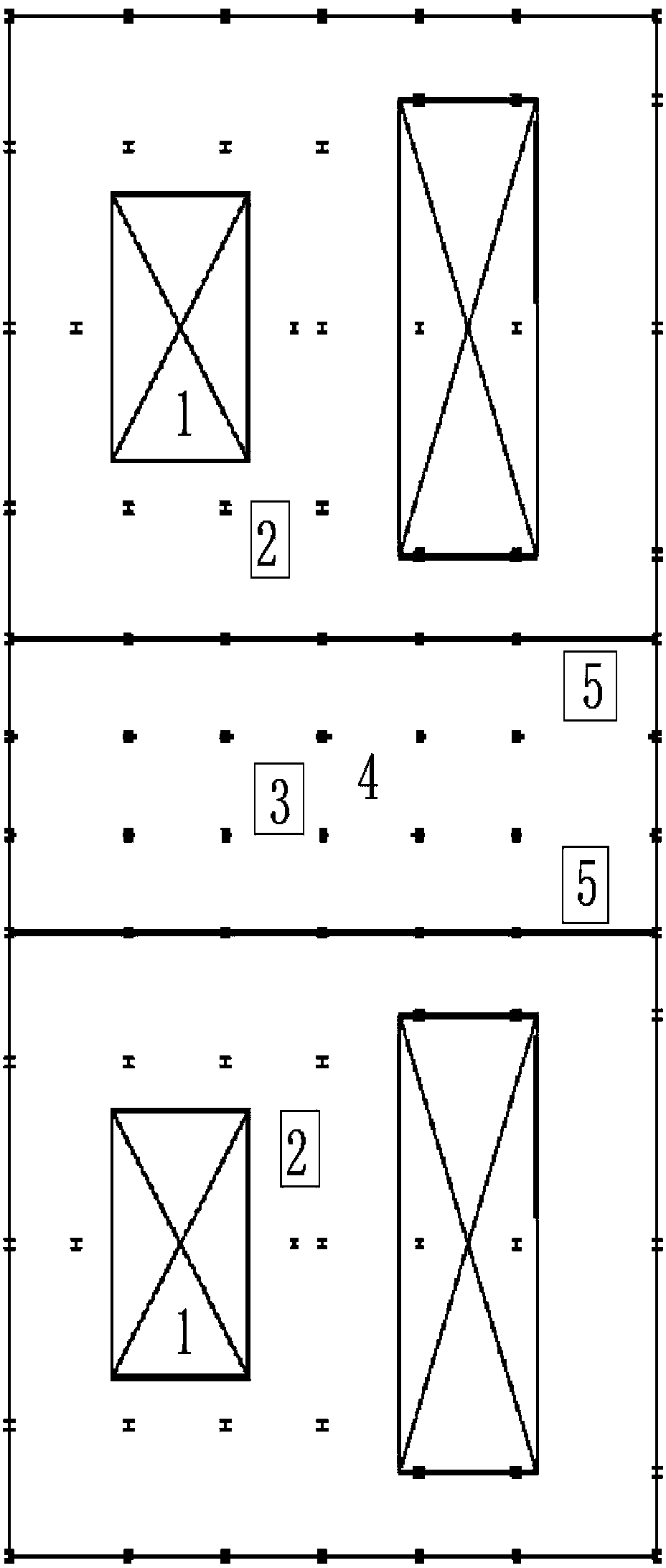

[0021] A joint structure system between pulverized coal boiler and side coal bunker in coal-fired power station, as attached figure 2 As shown, there are two boilers 1, between which there is a coal bunker 3 used jointly by the coal mills 5 of the two boilers, and the steel frame 2 of the two boiler bodies passes through the steel frame 4 between the coal bunkers. Connected as a whole, the coal bunker room 3 is provided with two boiler coal mills 5 installation areas corresponding to the two boilers. For other references to Embodiment 1, details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com