A zero-power consumption compound fertilizer granulation tower

A technology of granulation tower and compound fertilizer, which is applied in the direction of wind power motor combination, fertilizer form, fertilization device, etc., can solve the problems of high production cost and large energy consumption, and achieve the effects of low production cost, reduced energy consumption and stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

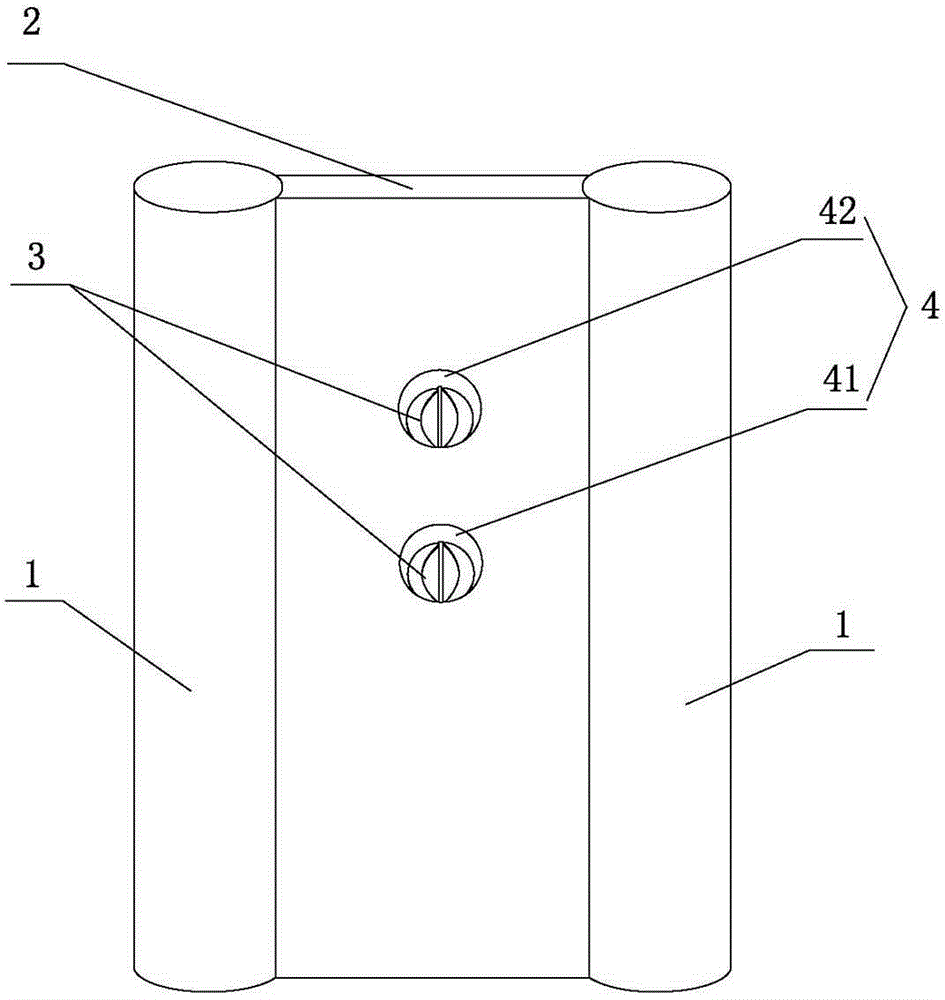

[0030] Such as figure 1 As shown, a zero-power consumption compound fertilizer granulation tower includes a vertical granulation tower 1, a wind gathering device 2 and a magnetic levitation wind generator 3, the wind gathering device 2 is connected to the vertical granulation tower 1, and the wind gathering The device 2 is provided with an air duct 4, the magnetic levitation wind power generator 3 is arranged in the air duct 4, the magnetic levitation wind power generator 3 is electrically connected with the power system of the vertical prilling tower 1, the vertical prilling tower 1 The number is two, and the wind gathering device 2 is arranged between two vertical prilling towers 1, and the two ends of the wind gathering device 2 are respectively connected with the vertical prilling towers 1. The present invention adopts its own wind power generation equipment as the power supply, which is energy-saving and environmentally friendly, can realize uninterrupted power supply, s...

Embodiment 2

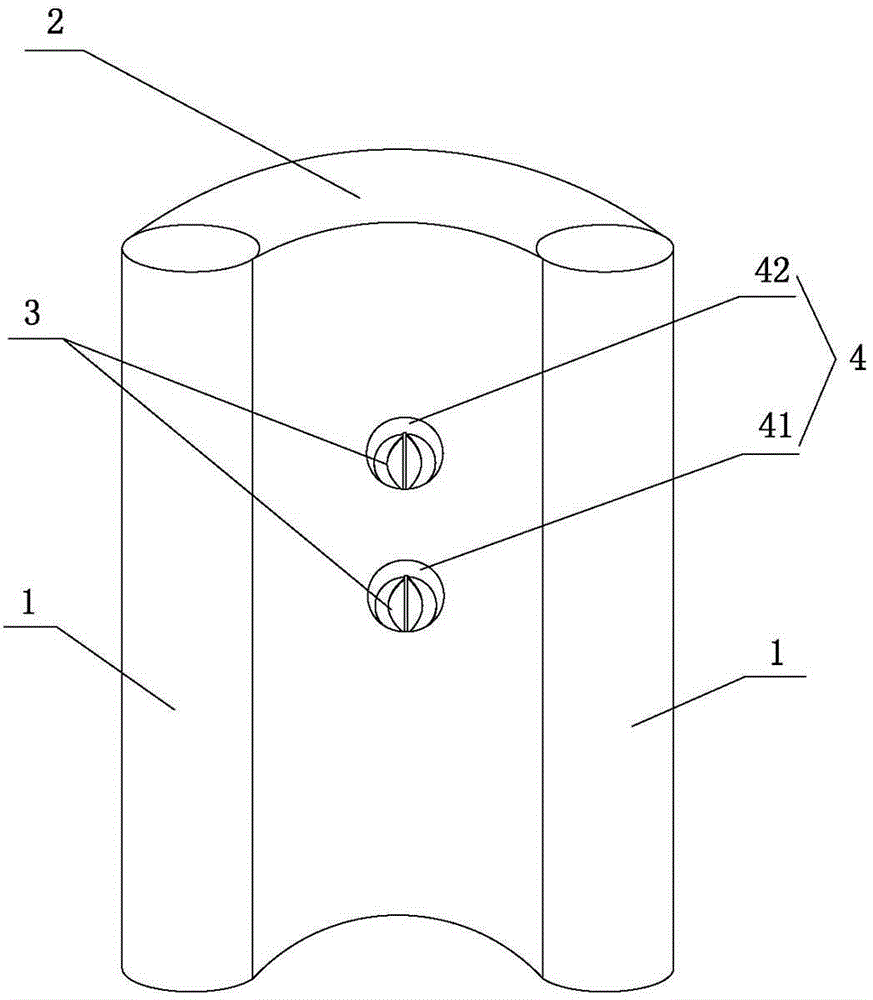

[0040] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the first air duct 41 of this embodiment is located in the middle of the wind gathering device 2, and the distance between the first air duct 41 and the top of the wind gathering device 2 is 40 m. The second air channel 42 is located on the upper part of the wind collecting device 2, and the distance from the second air channel 42 to the top of the wind collecting device 2 is 20 m.

[0041] The cross-section of the wind-accumulating wall in this embodiment is arc-shaped, the windward side of the wind-accumulating wall is concave inward to form a curved surface, and the leeward side protrudes outward. By adopting this solution, the area of the windward side of the wind gathering wall can be further increased, which is conducive to gathering more natural wind, the wind speed of the natural wind in the air duct 4 is further improved, and the power generation of the magnetic levita...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com