Vacuum-pumping system and vacuum-pumping method for large-capacity low-temperature thermal insulating container

A vacuum pumping system, low temperature insulation technology, applied in pressure vessels, fixed-capacity gas storage tanks, mechanical equipment, etc., can solve the problem of no heating source in the outer tank, vacuum degree, low leakage and deflation rate indicators, easy to explode, etc. problems, to achieve the effect of improving the leakage rate index, shortening the evacuation cycle, and improving the vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

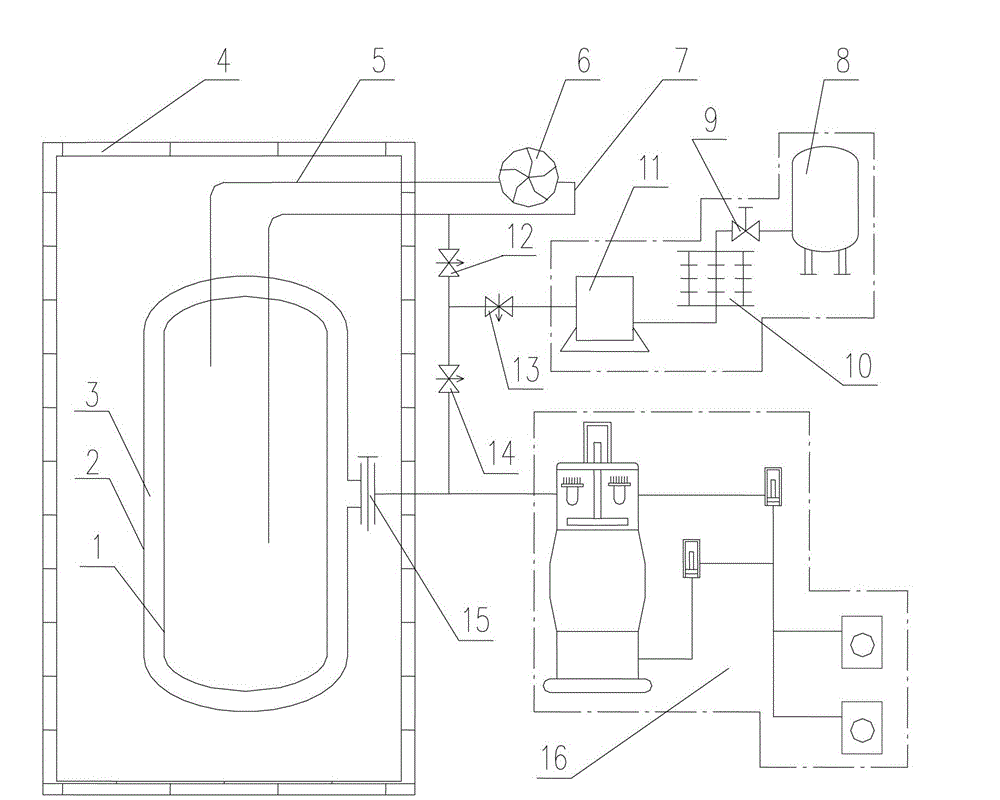

[0034] see figure 1 , The present invention provides a vacuum pumping system for a large-volume low-temperature heat-insulating container, which is mainly composed of four parts: a multi-layer heat-insulating container, a heating device, a gas supply device and a vacuum pumping device. The multi-layer thermal insulation container is composed of an inner tank 1, an outer tank 2 and an interlayer 3; the interlayer 3 is formed by the outer tank 2 and the inner tank 1. The heating device includes an outer tank heating device and an inner tank heating device, wherein the outer tank heating device is arranged outside the outer tank of the heat-insulating container to be evacuated; the inner tank heating device is arranged inside the inner tank of the heat-insulating container to be vacuumed; the gas supply device The pipes are respectively connected with the inner tank and the interlayer of the heat-insulating container to be evacuated; the vacuum device is respectively connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com