Multistage variable-temperature and variable-pressure steam heating device and heat exchange system thereof

A steam heating device, multi-stage technology, applied in the direction of steam generation, feed water heater, steam generation method, etc., can solve the problems of steam production speed/power ratio, low energy efficiency, energy waste, etc., and achieve high effective power, high The effect of energy efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

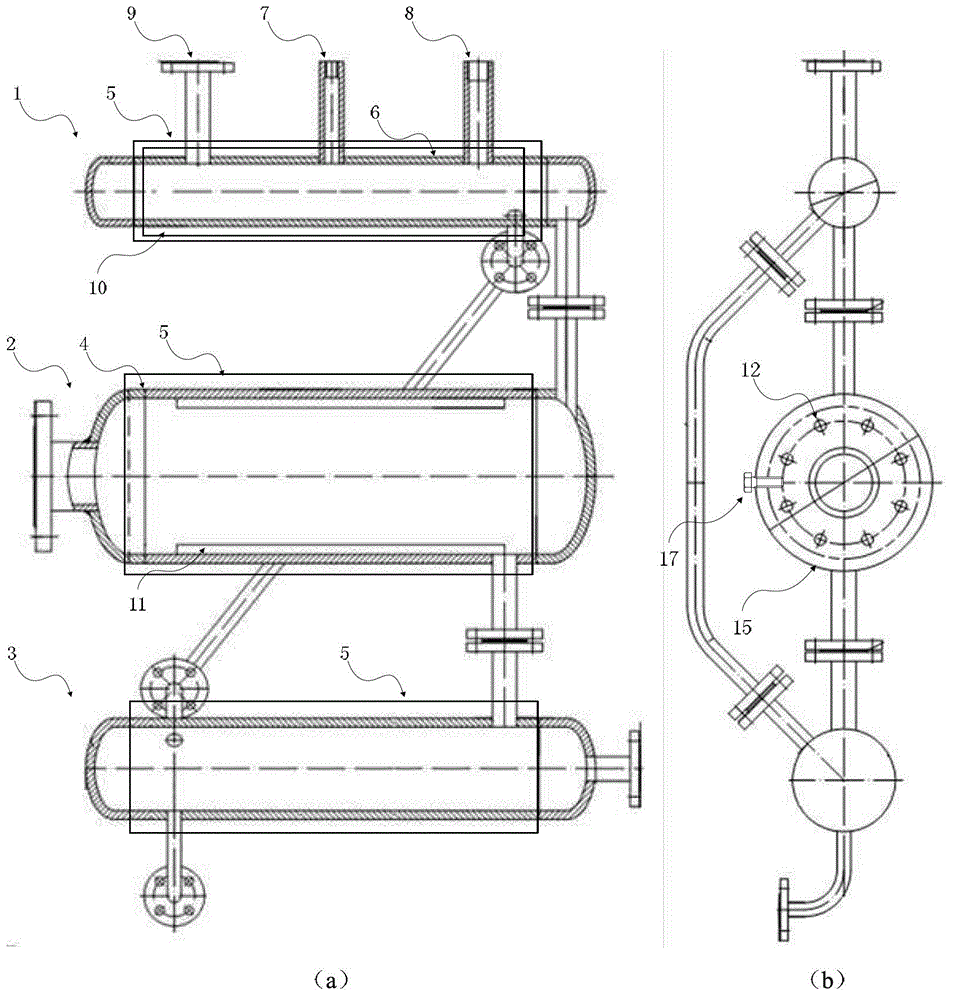

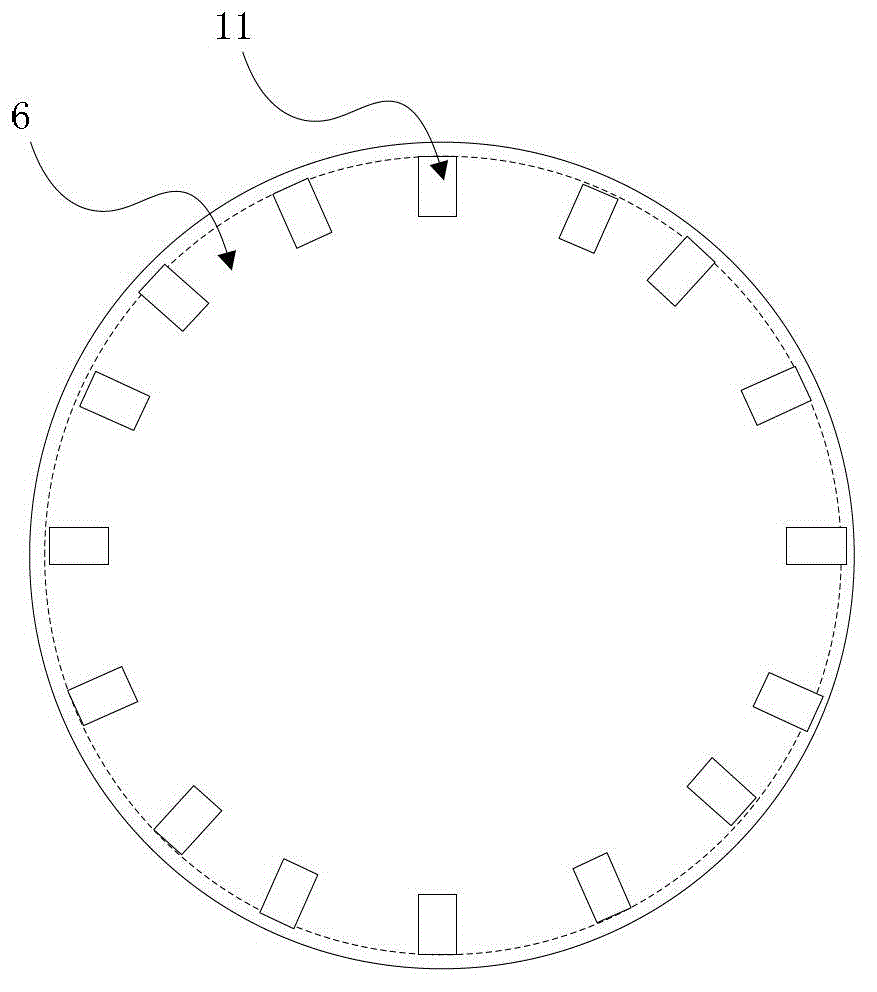

[0039] like figure 1 As shown in (a), this embodiment relates to a multi-stage adjustable temperature and pressure steam heating device 0 comprising: an output unit 1, a feedback unit 2 and a heating unit 3 with an atomizing nozzle group 4, wherein: the output The input end of the unit 1 is connected to the output end of the heating unit 3 and the output end of the feedback unit 2, the feedback end of the heating unit 3 is connected to the input end of the feedback unit 2, and the atomizing nozzle group 4 is arranged at the input end of the heating unit 3, so The output unit 1 , the heating unit 3 and the feedback unit 2 are all provided with an electromagnetic induction heating device 5 .

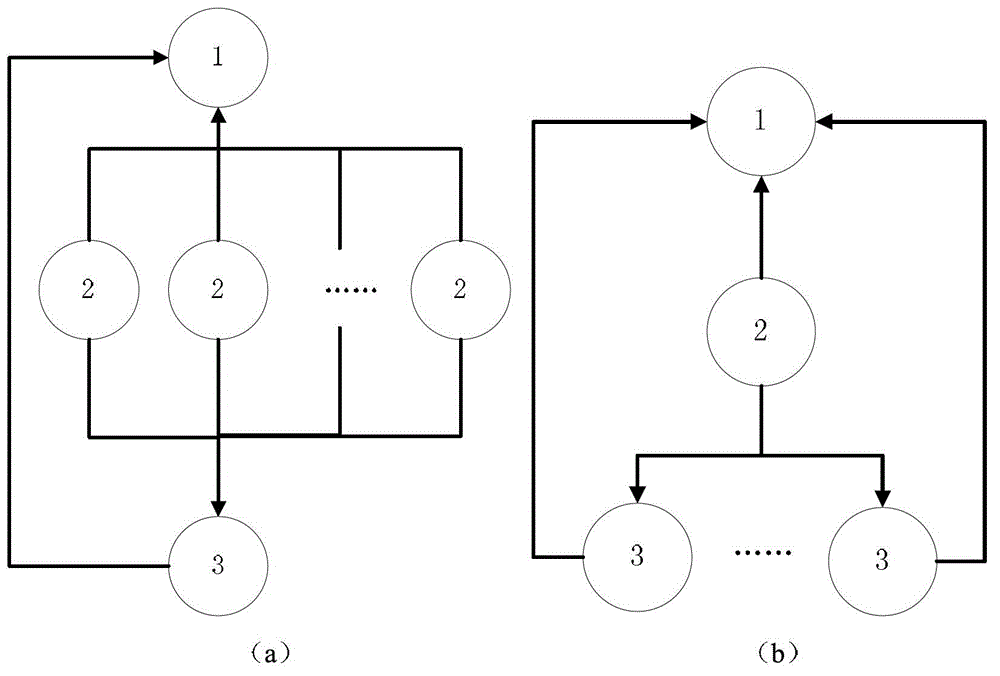

[0040] like figure 2 (a) and figure 2 As shown in (b), in the actual application process, you can also refer to the following methods for setting, such as:

[0041] a) a combination of an output unit 1, several heating units 3 and a feedback unit 2, or

[0042] b) The combination of ...

Embodiment 2

[0055] like Figure 8 As shown, in this embodiment, a multi-stage adjustable temperature and pressure steam heat exchange system includes: a primary heating mechanism and the multi-stage adjustable temperature and pressure steam heating device 0 connected thereto, wherein: the primary heating The mechanism includes a water softening processor 18, a high-pressure water pump 19, a heat pump water heating unit 20, and a two-position three-way valve 21 connected in series. Valve 22 groups are connected with multi-stage adjustable temperature and pressure steam heating device O.

[0056] The two-position three-way valve 21 is set to shut off the water temperature to 85°C;

[0057] like Figure 8 and Figure 9 As shown, a solenoid valve 22 is preferably set between the primary heating mechanism and the multi-stage adjustable temperature and pressure regulating steam heating device O, the solenoid valve 22 can control the outlet water temperature of the primary heating mechanism, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com