Full-automatic constant temperature instant boiling type gas water boiler

A fully automatic, water boiler technology, applied to water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of stopping production to remove scale, water not reaching the boiling point, high energy consumption, etc., and achieve the goal of saving fuel energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

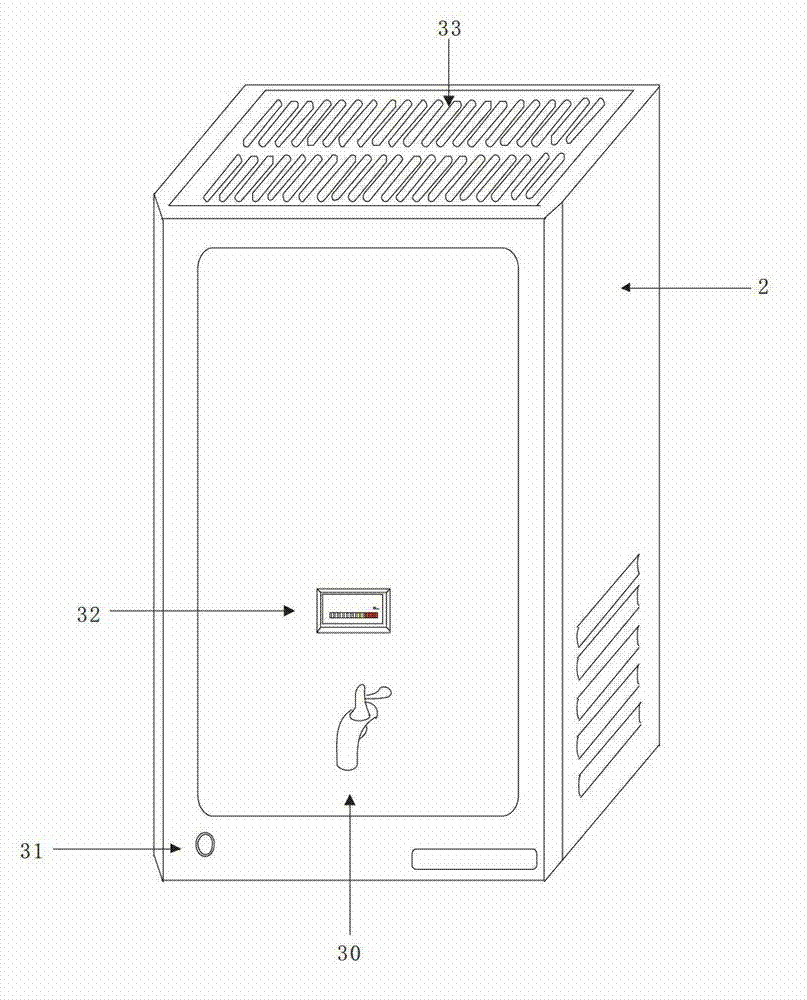

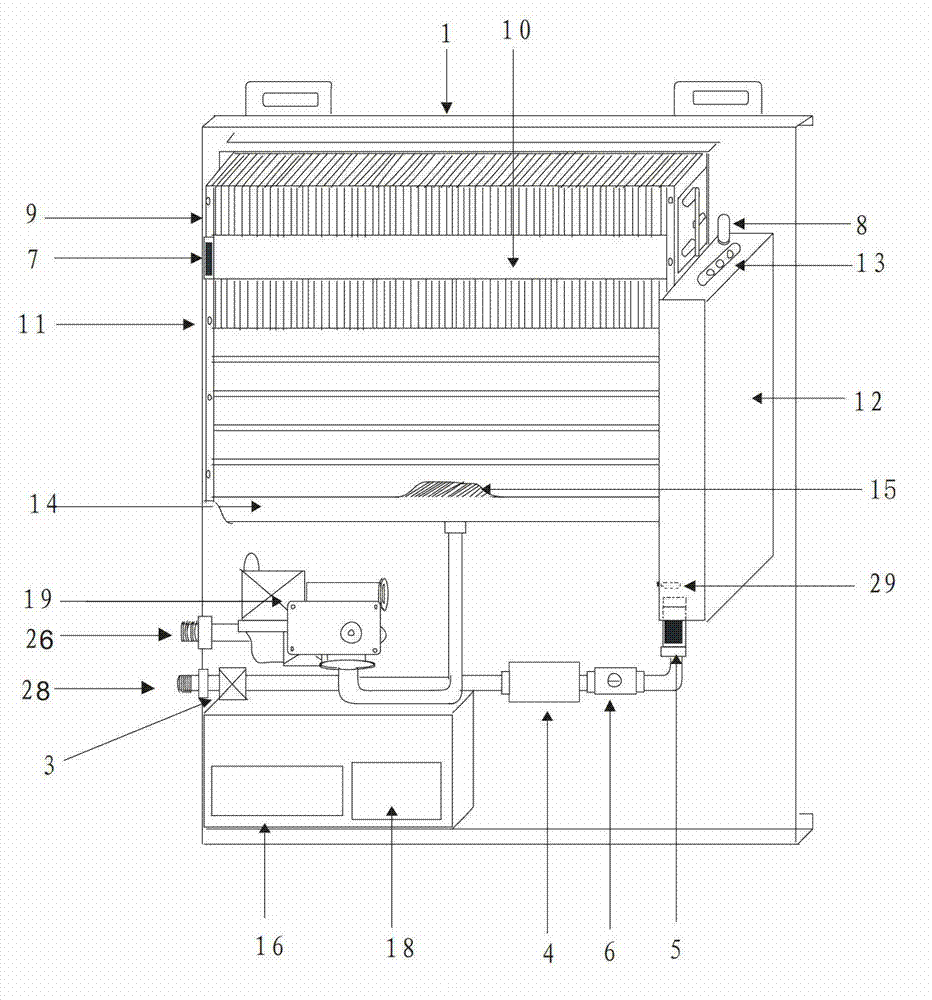

[0037] Such as Figure 1-4 As shown, in a preferred embodiment of the present invention, the fully automatic constant temperature instant boiling gas water boiler includes a water inlet system, an air inlet system, a heating system, a water outlet system and a microcomputer control device;

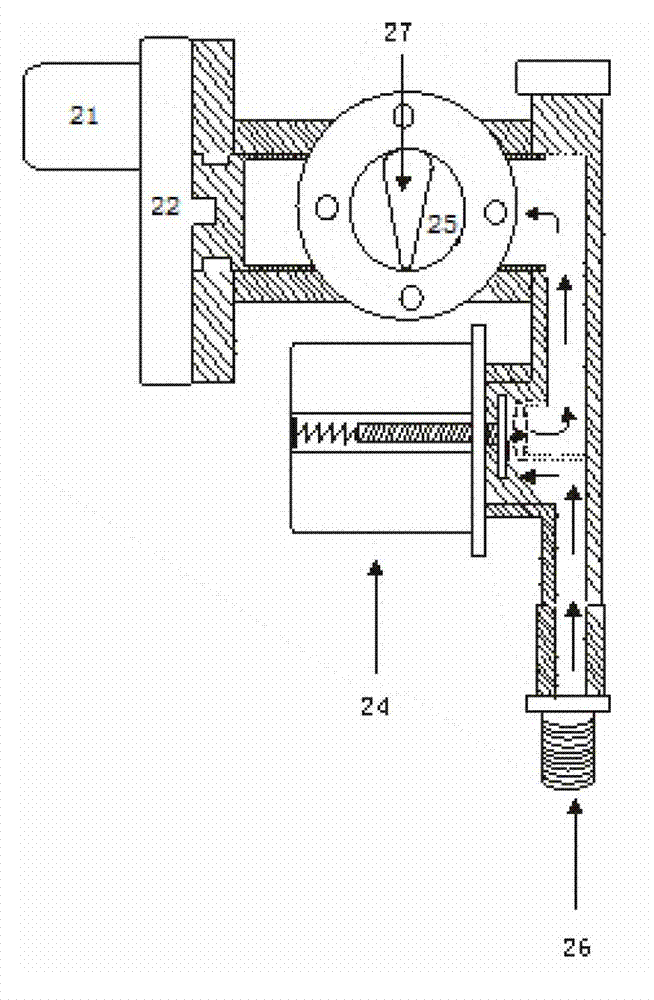

[0038] Such as figure 2 As shown, the air intake system is made up of gas pipelines 25, 26 and a gas valve assembly 19 of a deceleration motor, and the gas valve assembly 19 of a deceleration motor is connected with the heating system through a gas pipeline 25; and the gas valve assembly 19 of a deceleration motor is connected with a microcomputer device 16.

[0039] Such as Figure 3 ~ Figure 4 As shown, the geared motor gas valve assembly 19 includes a self-priming solenoid valve 24 and an intake air flow regulating device. The self-priming solenoid valve 24 is arranged on the gas pipeline 26 connecting the gas inlet and the intake flow regulating device, and connected with the micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com