Light-splitting synchronous phase shifting interference microscopy device and detection method

A synchronous phase-shifting and interference microscopy technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of low measurement accuracy, complicated and difficult operation, etc., and achieve the effect of simple mapping relationship, convenient and flexible operation, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

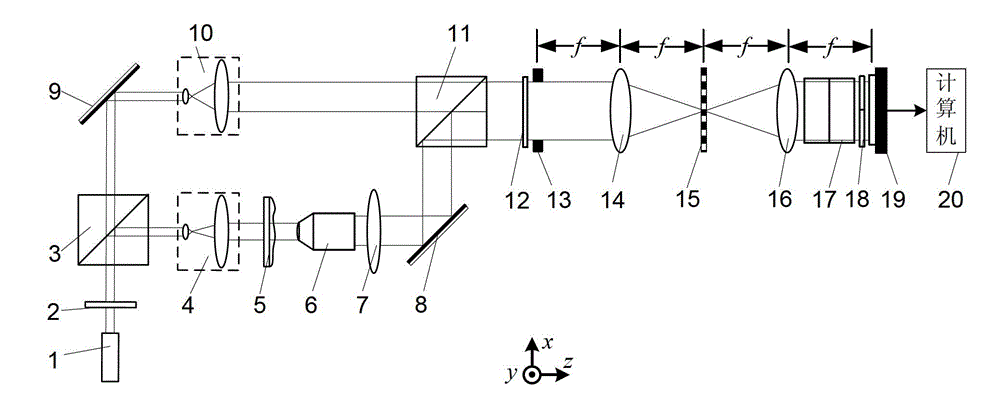

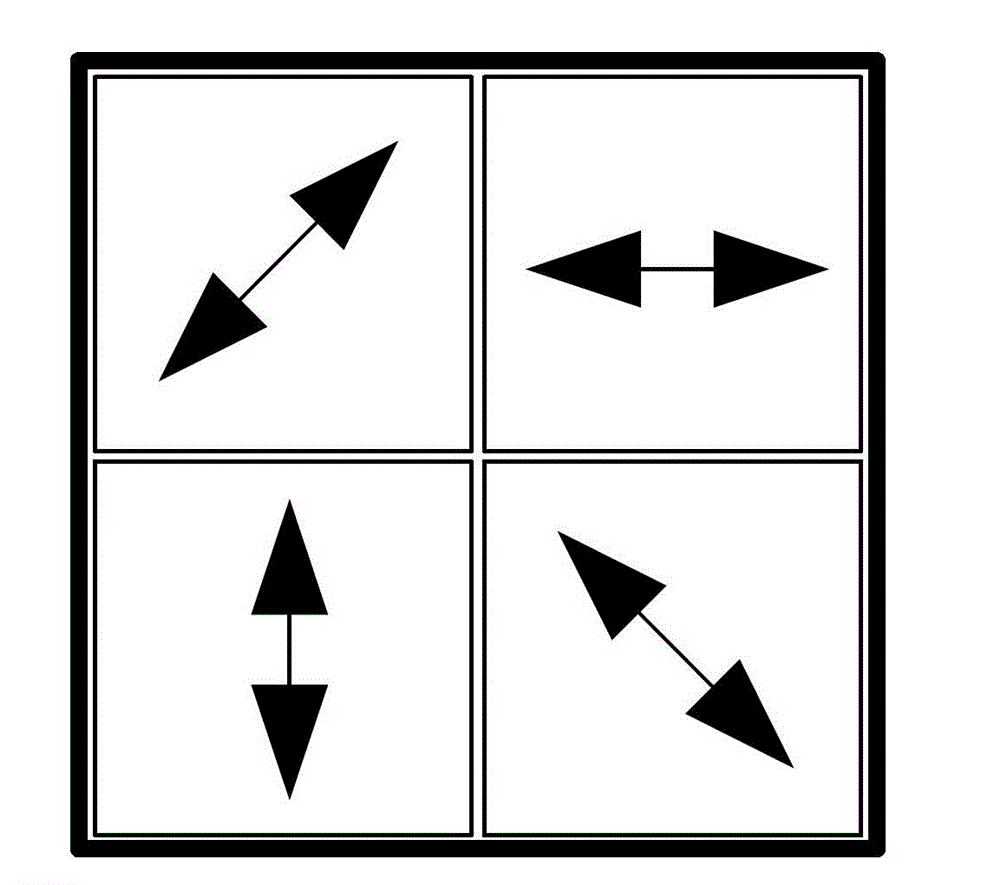

[0034] Specific implementation mode one: the following combination Figure 1 to Figure 4 Describe the present embodiment, the spectroscopic synchronous phase-shifting interference microscopic detection device described in the present embodiment, it comprises light source 1, and it also comprises polarizer 2, the first polarizing beam splitting prism 3, the first collimating beam expander system 4, to-be-measured Object 5, microscope objective lens 6, correction objective lens 7, first mirror 8, second mirror 9, second collimator beam expander system 10, second polarization beam splitter prism 11, λ / 4 wave plate 12, rectangular window 13 , a first Fourier lens 14, a one-dimensional periodic grating 15, a second Fourier lens 16, a depolarizing beamsplitter prism 17, a four-quadrant polarizer group 18, an image sensor 19 and a computer 20, where λ is the light beam emitted by the light source 1 wavelength of light,

[0035] The light beam emitted by the light source 1 enters the...

specific Embodiment approach 2

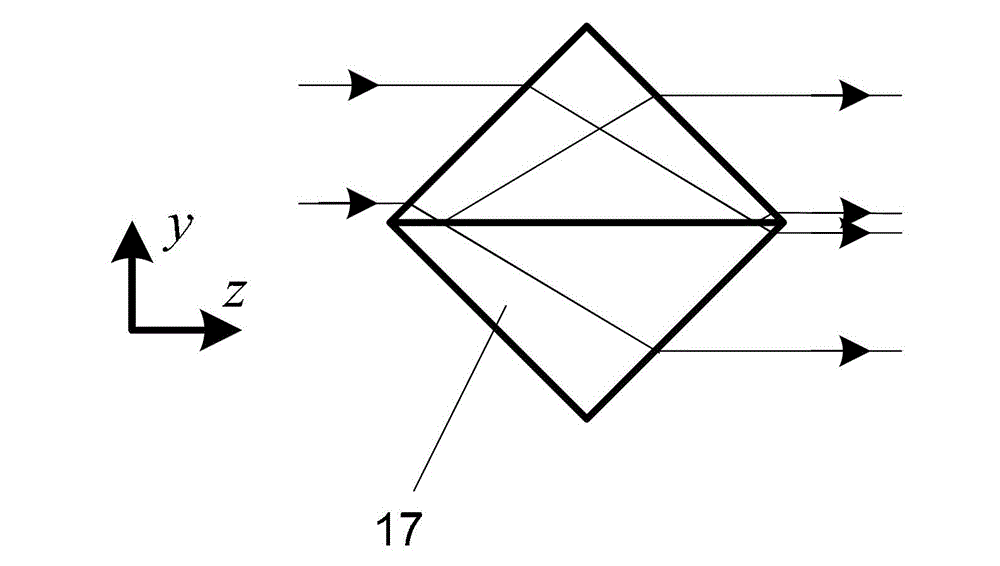

[0045] Specific implementation mode two: the following combination figure 2 Describe this embodiment mode, this embodiment mode will be further described to Embodiment 1, the depolarization dichroic prism 17 is placed according to the mode that its dichroic surface is parallel to the plane formed by x-axis and z-axis, and the incident light is from 45° or -45° to its dichroic plane. ° Angle of incidence.

specific Embodiment approach 3

[0046] Embodiment 3: In this embodiment, Embodiment 1 or Embodiment 2 is further described. The one-dimensional periodic grating 15 is a binary one-dimensional periodic grating or a sine one-dimensional periodic grating or a cosine one-dimensional periodic grating.

[0047] In this embodiment, the one-dimensional periodic grating 15 adopts a Ronchi grating with period d=50 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com