Nano stress sensor based on metal nano gap and preparation method thereof

A stress sensor and metal nanotechnology, which is applied in the coating process of metal materials, processes and instruments for producing decorative surface effects, etc., can solve the problems of slow, low industrial value of stress changes, controllable realization and electrode laying difficulties. and other problems, to achieve the effect of fast response, easy miniaturization and miniaturization, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

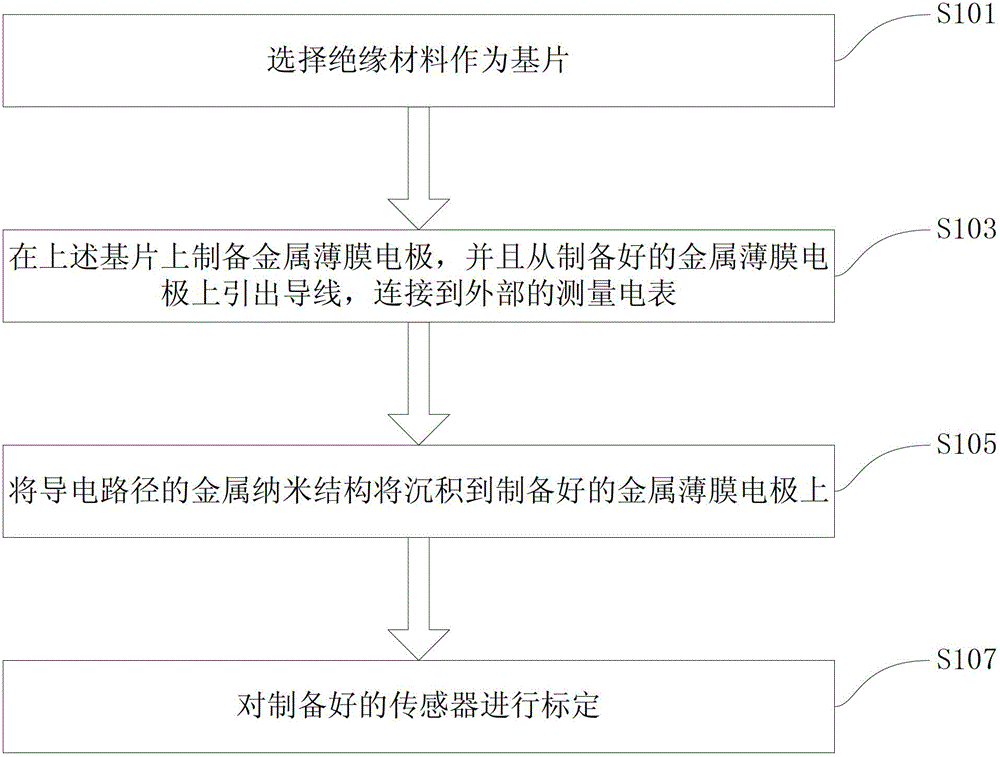

[0024] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

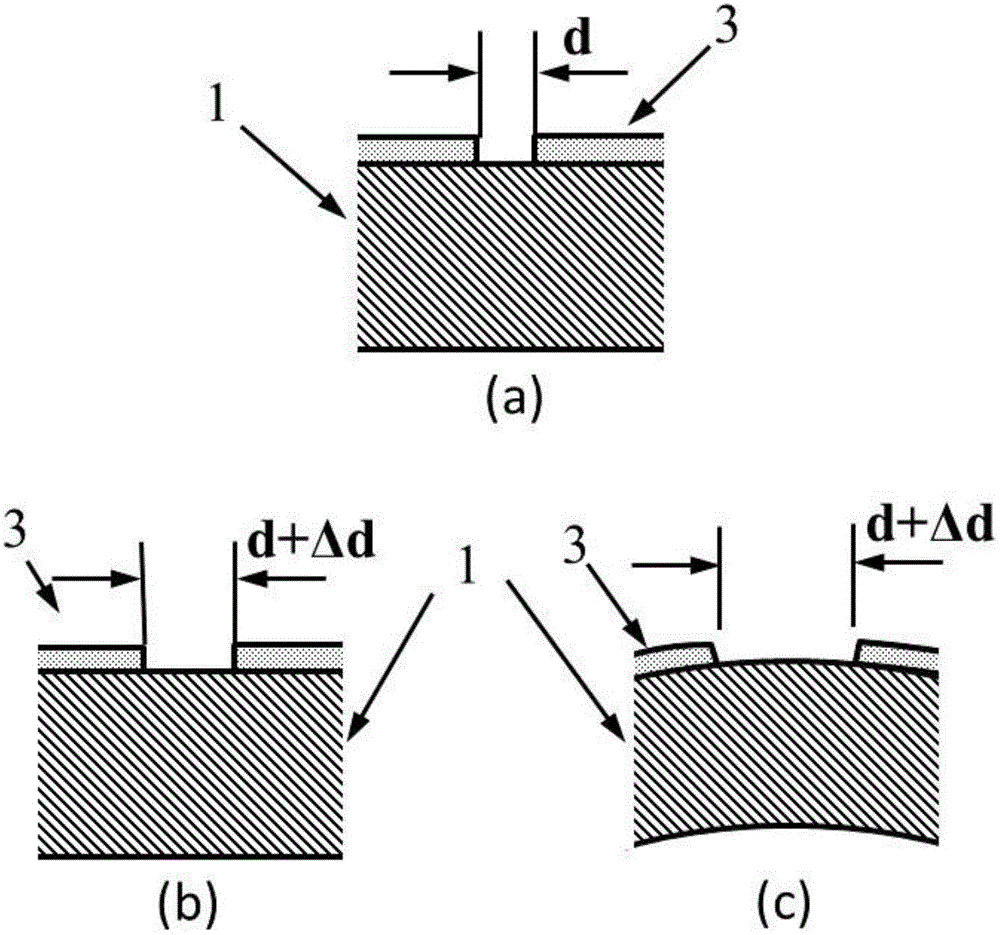

[0025] Firstly, the method of sensing using the nanogap is introduced. The principle is as figure 1 shown, if any figure 1 (a) shows a nanoscale gap d, the current I∝Ve between metal nanostructures (3) (which can be bulk or metal nanospheres) -kd , where V is the voltage across the nanogap. If there is local stress or strain on the substrate, such as figure 1 (b) is the tensile stress, figure 1 (c) is the shear stress, no matter which stress mode it is, it will cause the metal gap d to change Δd, and the tunneling current will change sensitively.

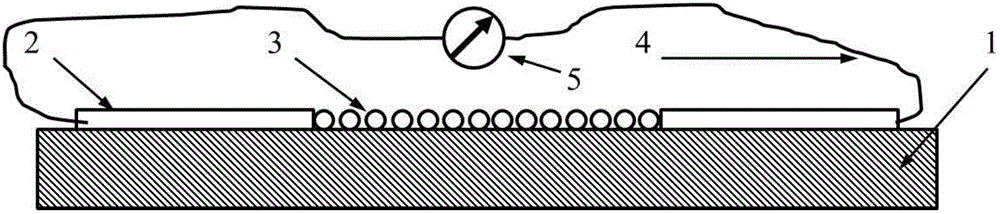

[0026] figure 2 It is a schematic structural diagram of a nano-stress sensor based on a metal nano-gap according to an embodiment of the present invention. Such as figure 2 As shown, the nano-stress sensor based on the metal nano-gap includes: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com