A long-life gray control rod and absorber

A technology for absorbers and control rods, applied in the field of reactivity control in nuclear power plants, can solve problems such as reducing or no longer satisfying the reactivity value of ash control rod components, and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of long-life ash control rod of the present invention, it is elongated solid tubular structure, is made of thulium oxide (Tm 2 o 3 )production. The gray control rod is clad with a cladding tube made of stainless steel or nickel-based alloy.

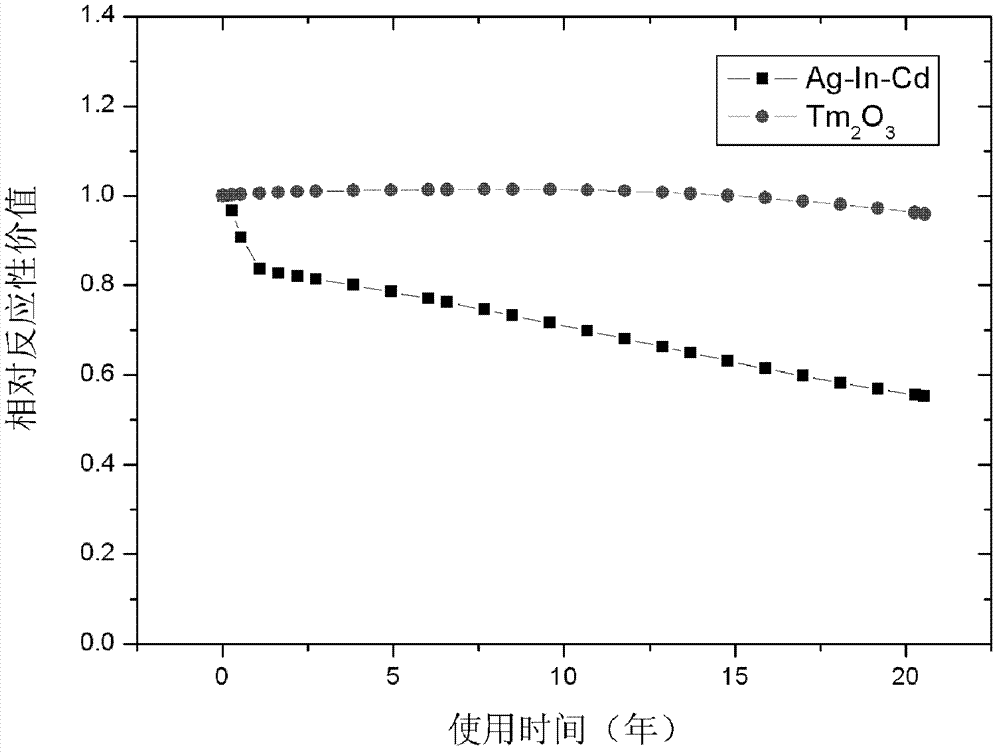

[0022] Such as figure 1 As shown, the existing gray control rod design uses Ag-In-Cd alloy as the absorber. The Ag-In-Cd alloy has a relatively large neutron absorption cross-section, especially the neutron absorption cross-section of the product of the naturally occurring isotope transmutation of the three elements of Ag, In and Cd is significantly reduced, so the Ag-In-Cd The reactivity value of the ash control rod with the alloy as the absorber decreases very quickly with the burnup, and drops to about 80% of the initial value in about 5 years, which no longer meets the requirements of the MSHIM model for the reactivity value of the ash control rod assembly .

[0023] Such as figure 1 As shown, Tm is used in this em...

Embodiment 2~15

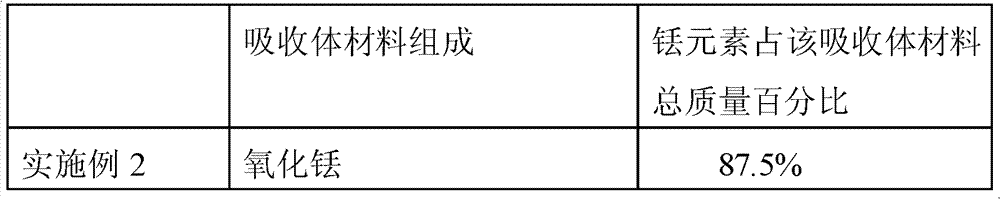

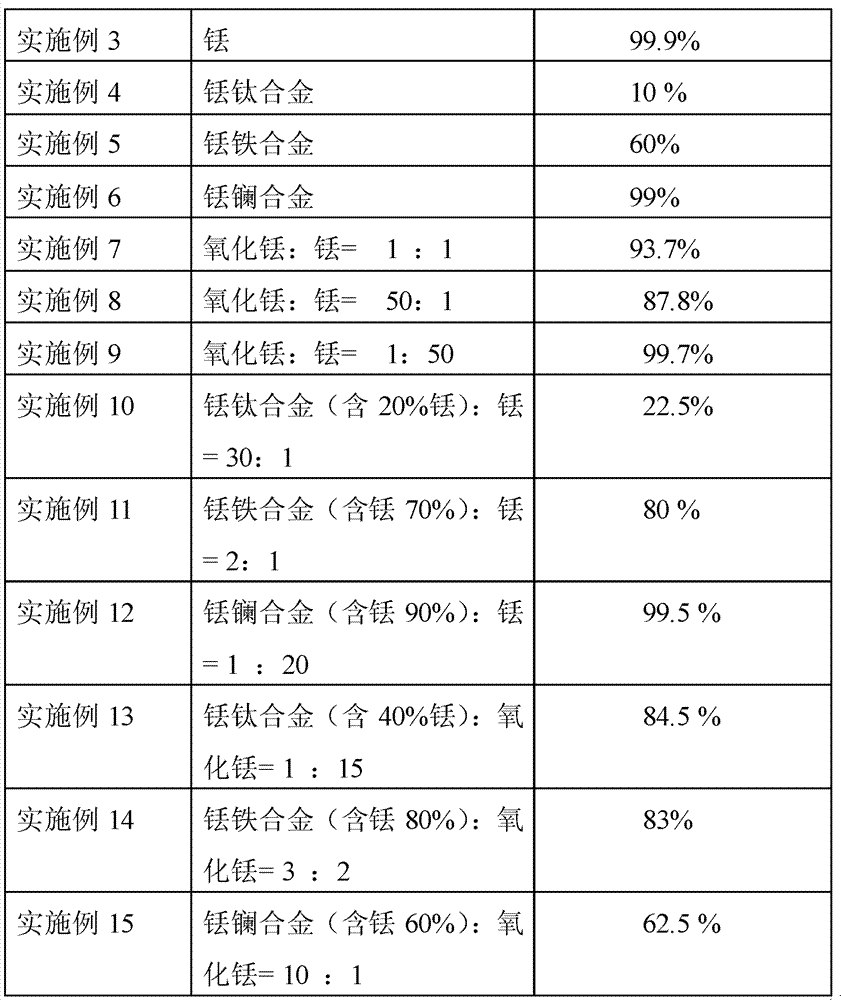

[0025] The absorber material for long-life gray control rods of the present invention contains one or more of thulium, thulium alloy or thulium oxide, and the specific composition is shown in Table 1 below. (The absorber material may also contain impurity components such as Gd, Tb, Dy, Eu, Sm, Er, Ho, etc. not exceeding 2%.)

[0026] Table 1

[0027]

[0028]

Embodiment 16

[0030] A long-life gray control rod according to the present invention, the gray control rod is a concentrically arranged inner and outer two-layer slender solid tubular structure; the gray control rod is covered with a cladding tube made of stainless steel or nickel-based alloy.

[0031] The inner tube is made of thulium oxide, and the diameter of the inner tube is 3mm;

[0032] The outer tube is made of Inconel 718 alloy, the inner diameter of the outer tube is 3mm, and the outer diameter is 8mm;

[0033] Wherein, the thulium element in the gray control rod accounts for 13% of the total mass percentage of the gray control rod.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com