High temperature resistant flexible power control composite cable

A power control and integrated cable technology, applied in the field of integrated cables, can solve problems such as easy drop, interference with control signal cable signal transmission, cable temperature resistance level and flexibility not meeting customer requirements, etc., to improve high temperature resistance performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

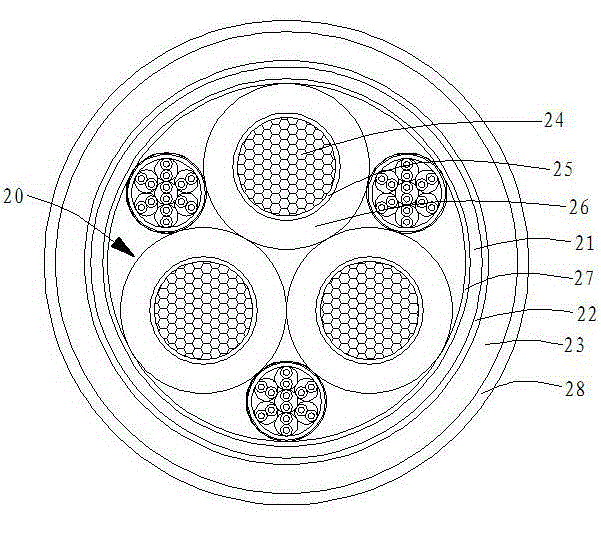

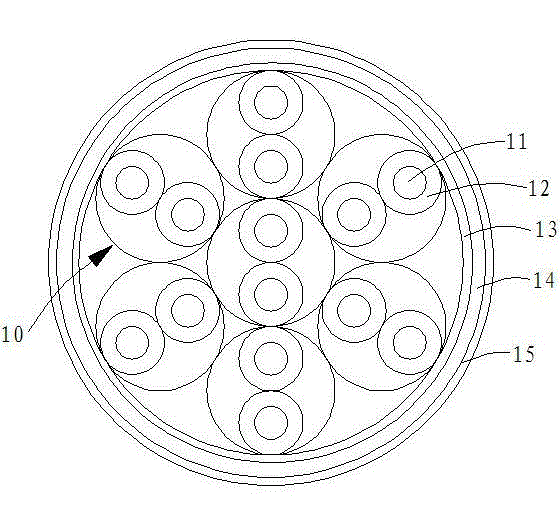

[0011] see figure 1 , figure 2 , the present invention is a kind of high temperature resistant flexible power control integrated cable, including control signal cable and cable, the control signal cable includes a plurality of control signal units 10 and a polyester tape layer 13 coated outside the plurality of control signal units 10, Each control signal unit 10 has two control signal conductor cores 11, and each control signal conductor core 11 is covered with a signal insulating layer 12; An inner sheath 21, an armor layer 22 and an outer sheath 23 outside a power transmission unit 20, the power transmission unit 20 includes a power conductor core 24 and mica coated on the outside of the power conductor core 24 in sequence tape layer 25 and power insulating layer 26, the control signal cable is arranged at the gap formed by the plurality of power transmission units 20; the inner wall of the inner sheath 21 is compounded with an inner metal wire braided shielding layer 27,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com