One-side arc welding device

An arc welding, single-sided technology, applied in arc welding equipment, welding equipment, auxiliary devices, etc., can solve the problems of non-formation of weld bead, time-consuming preparation operation, laborious repair operation of welded steel plate, etc., to prevent welding defects. The effect of generating and stabilizing the shape of the weld bead

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

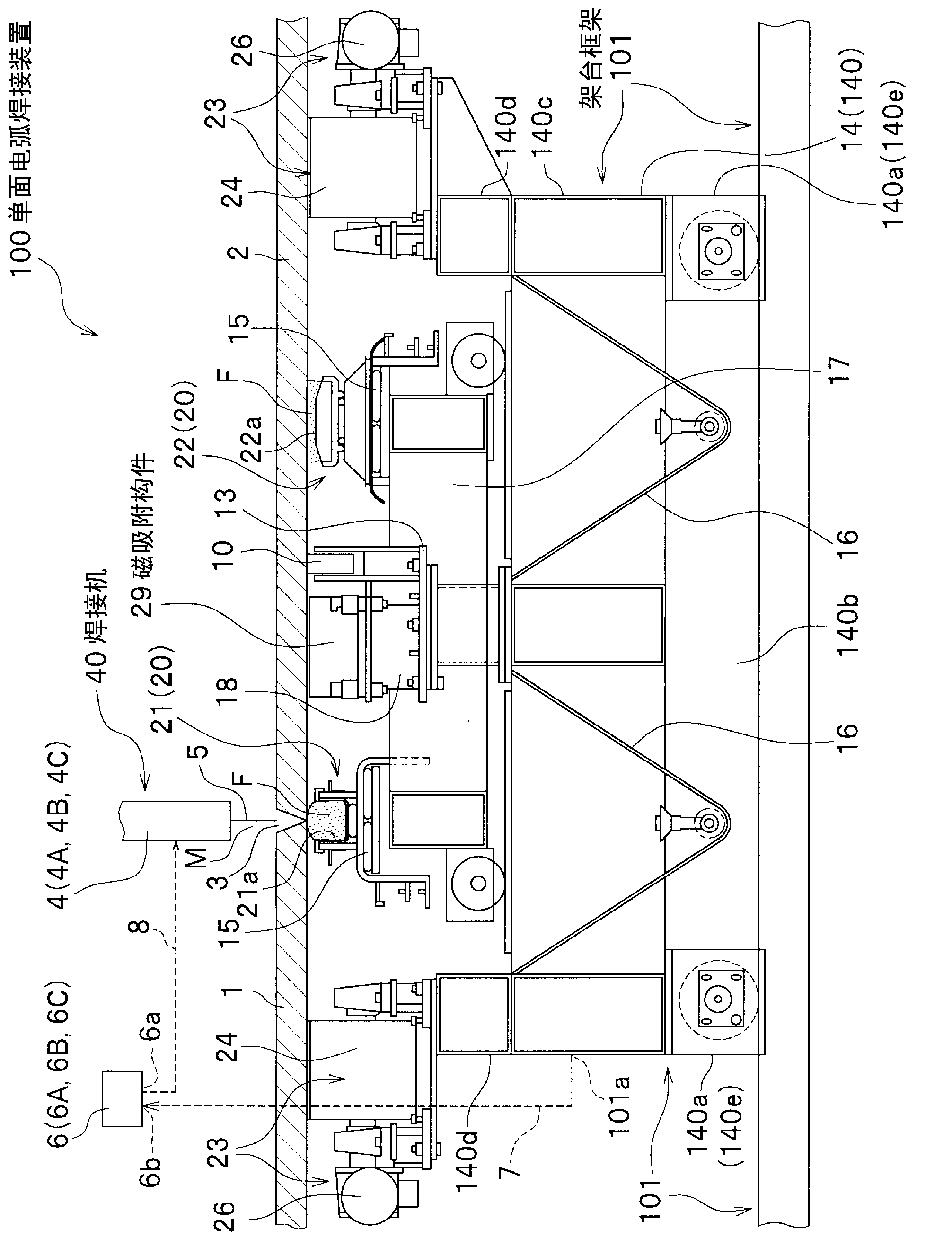

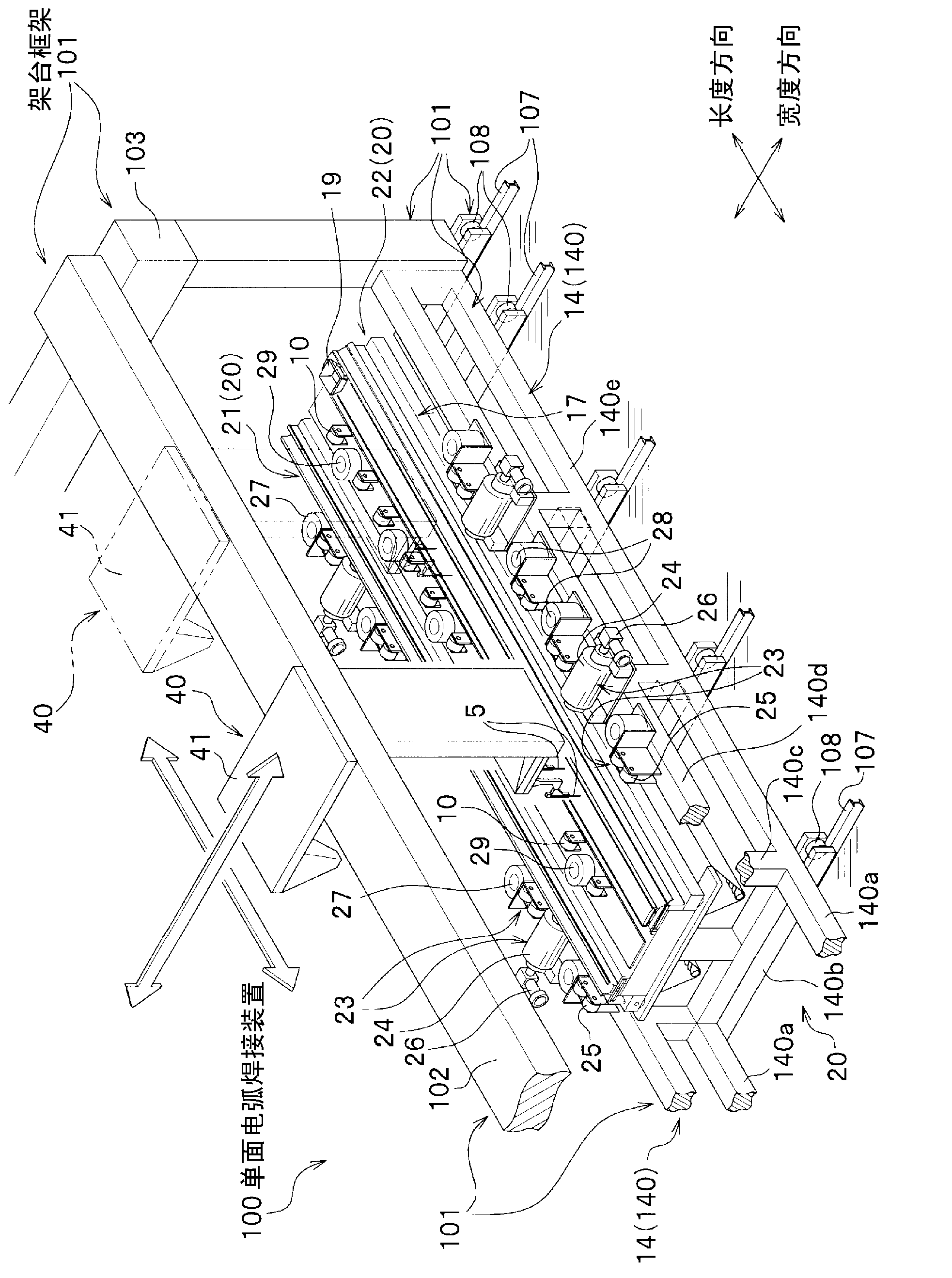

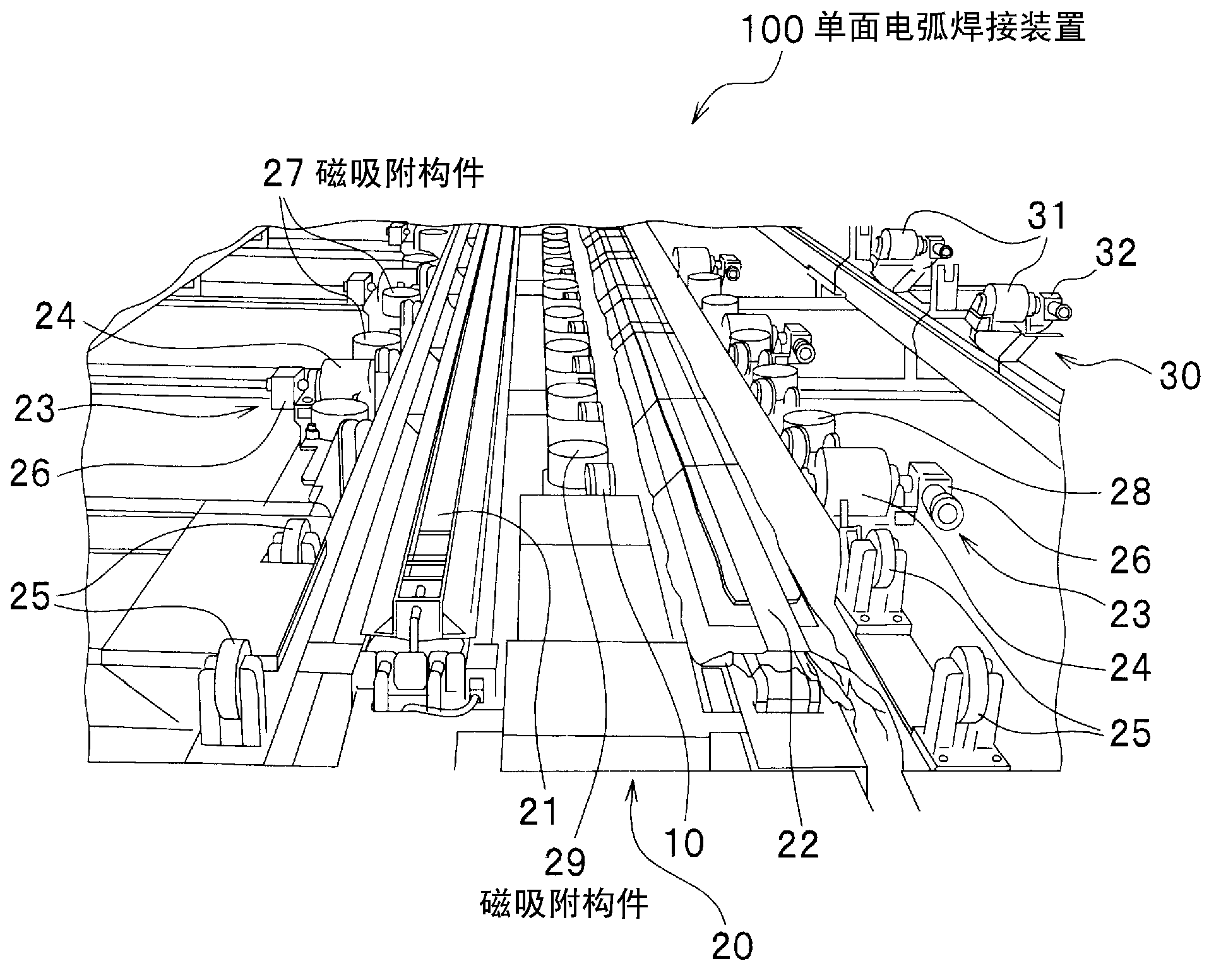

[0057] Below, refer to Figure 1 to Figure 5 Embodiments of the present invention will be described.

[0058] In addition, in the description of the embodiment, the longitudinal direction refers to the direction parallel to the welding line 3 of the steel plates 1 and 2 to be welded, and the width direction refers to the direction perpendicular to the welding line 3 .

[0059] Structure of single-sided arc welding device

[0060] Such as figure 1 As shown, the single-sided arc welding device 100 is a submerged arc welding device that performs single-sided welding of the steel plates 1 and 2 to be welded using flux F while moving the welding machine 40 along the welding line 3 . Such as figure 2 As shown, the single-sided arc welding device 100 respectively includes: a welding machine 40 described later; a welding power source 6 (6A, 6B, 6C); a stand frame 101; a welding material conveying device 23; magnetic adsorption members 27, 28, 29; Backing plate device 20; Elevatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com