Reinforcement of paper pulp-based materials using a reactive alkyd oligomer capable of forming a reprocessable reinforcement resin in situ

A reprocessing and pulping technology, applied in paper coating, papermaking, paper, etc., can solve problems such as high application temperature and expensive coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In this example, a reworkable alkyd coated liner was produced. Glycerin (1 molar equivalent) and citric acid (1 molar equivalent) were heated at 100°C for 60 minutes in a hot air oven to form a mixture comprising glyceryl citrate alkyd oligomer, glycerol, and citric acid. This mixture was added to various amounts of hot water to form prepolymer liquids having the following concentrations: 50%, 60%, 70%, 80% and 90% by weight based on the total weight of the prepolymer liquid. % by weight of water. At 20.5°C, and at 12g / m 2 , 14g / m 2 and 16g / m 2 Coating weights of each prepolymer liquid were applied to backing boards (99g / m 2 base weigh). The weight of coating applied is varied by adjusting the pressure and speed of the size press. The prepolymer liquid was then dried at 108°C for about 3 minutes or about 10 minutes.

Embodiment 2

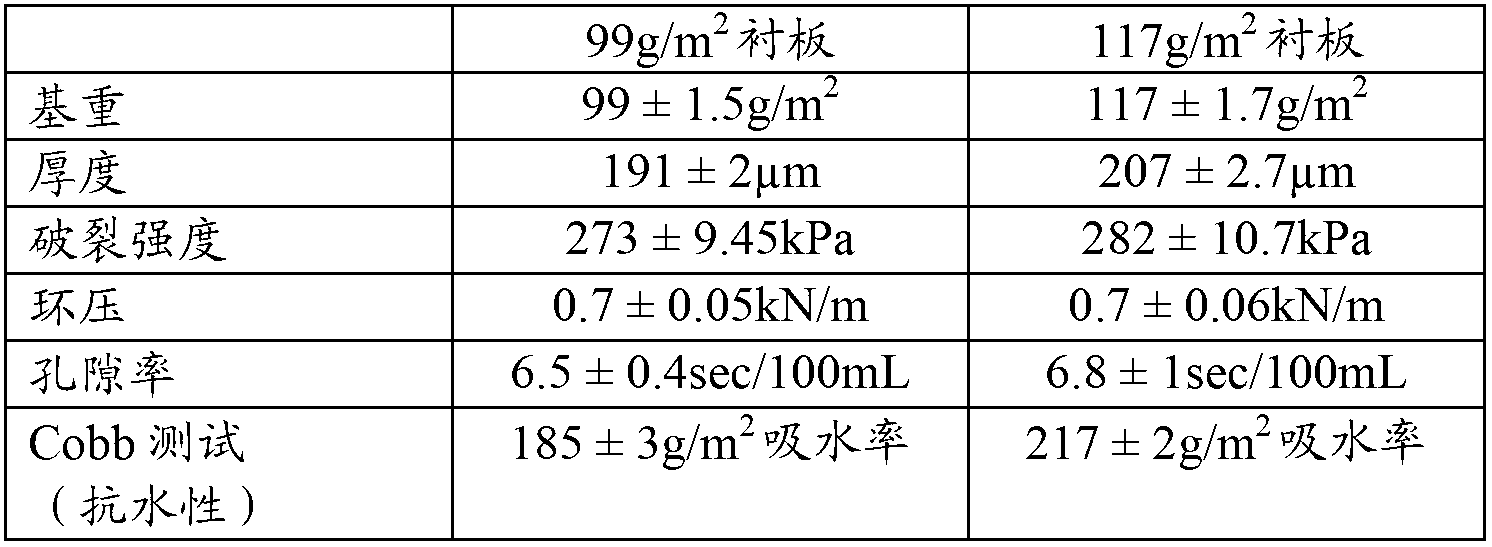

[0042] The mechanical properties of the coated liner from Example 1 were determined. Specifically, burst strength (TAPPI T810), thickness (TAPPI T411), water resistance (30 minute Cobb test, TAPPI T441), porosity (TAPPI T460) and ring pressure were determined for each alkyd coated liner (TAPPI T822). Compare the result with 117g / m 2 The basis weight of the uncoated liner was compared. Table 1 shows 99g / m 2 Basis weight and 117g / m 2 Mechanical properties of uncoated liners by basis weight.

[0043] Table 1 :

[0044]

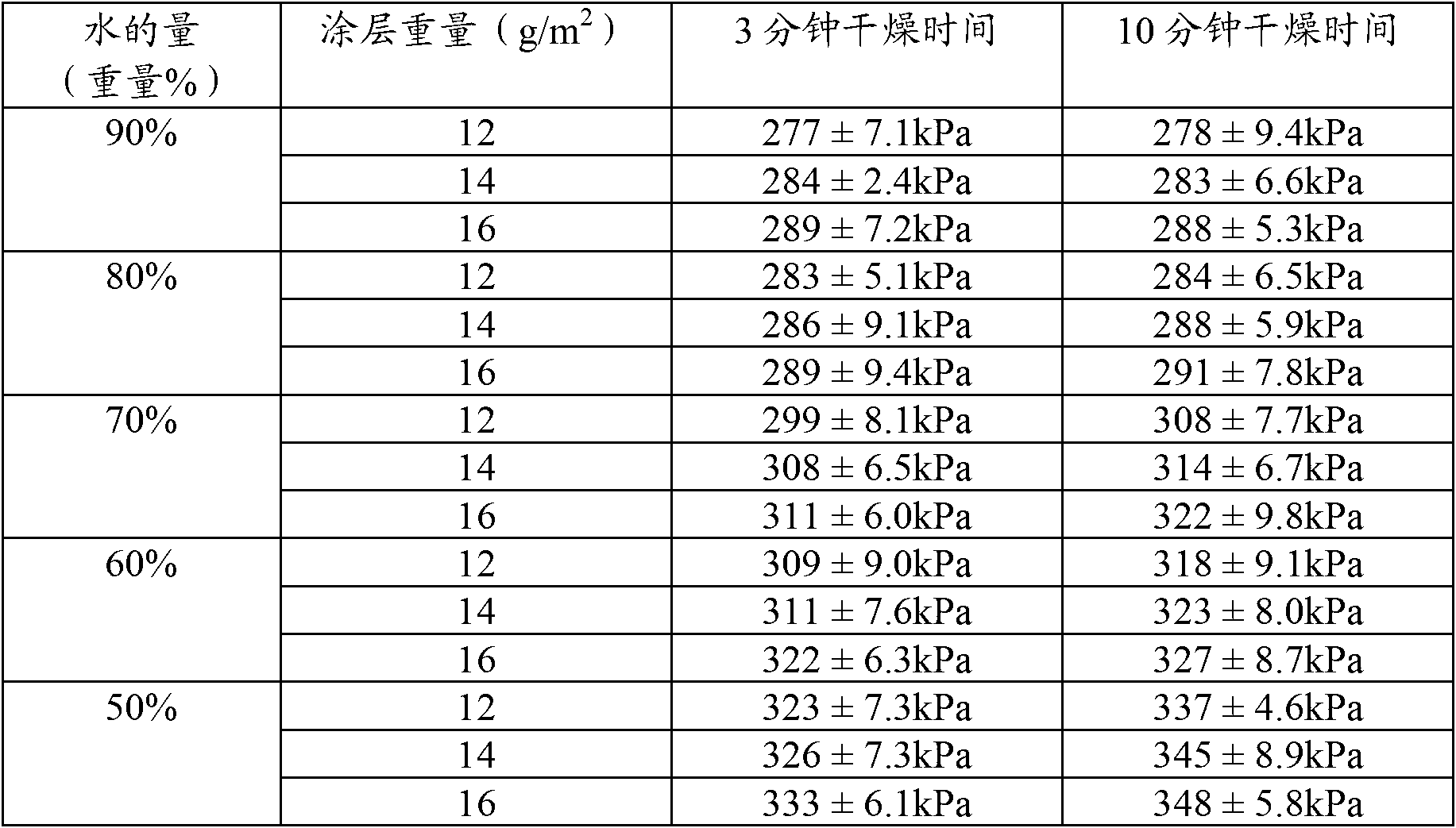

[0045] Bursting strength

[0046] Alkyd Coated 99g / m 2 The burst strength of the liner increases with coat weight and the amount of alkyd oligomers and monomers in the prepolymer liquid. As shown in Table 2, 99g / m2 coated with prepolymer liquid 2 The bursting strength of the liner exceeds 117g / m 2 The burst strength of an uncoated liner, the prepolymer liquid having from about 50% to about 70% by weight water, based on the total weight of the pre...

Embodiment 3

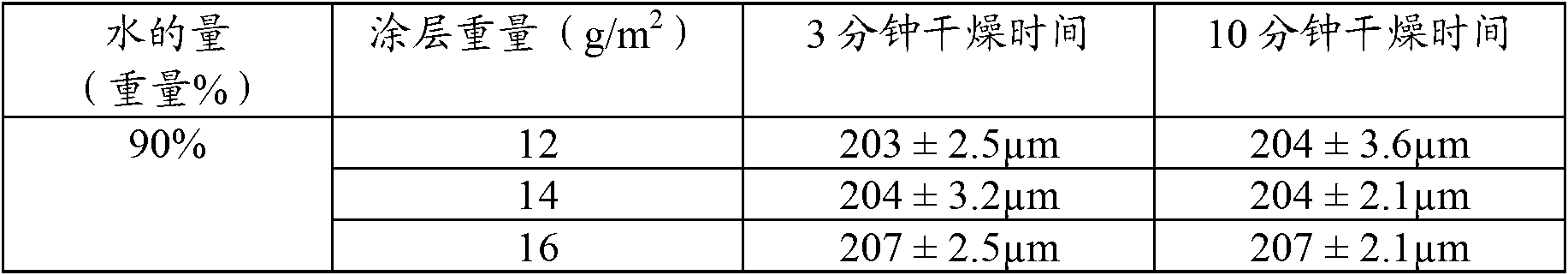

[0067] The amount of alkyd coating (on a dry weight basis) was determined to be 99g / m 2 The effect of liner burst strength and ring pressure. The alkyd coated liner was prepared as described in Example 1. Bursting strength and ring pressure were determined as described in Example 2. Compare the result with the 99g / m 2 and 117g / m 2 Basis weights of uncoated liners were compared (Table 7).

[0068] Table 7 :

[0069]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com