Mulching film convenient to recover

A technology of plastic film and body, which is applied in the field of field covering plastic film, can solve problems such as the inability to realize the mechanization of plastic film recycling, the difficulty of complete recycling of plastic film, and environmental pollution, so as to achieve efficient and sustainable development, save labor, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

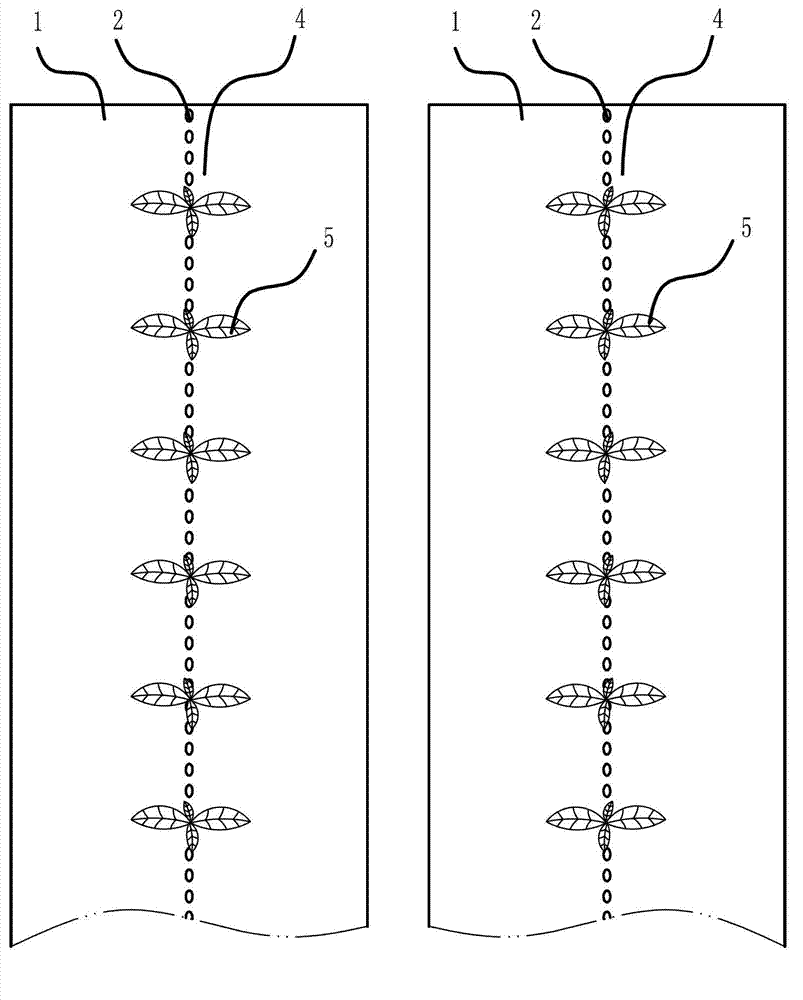

[0025] Embodiment one: if figure 1 As shown, the mulch film that is easy to recycle includes a mulch film body 1, and the mulch film body 1 is provided with opening slits 2 corresponding to the covered crop planting rows 4 along the length direction.

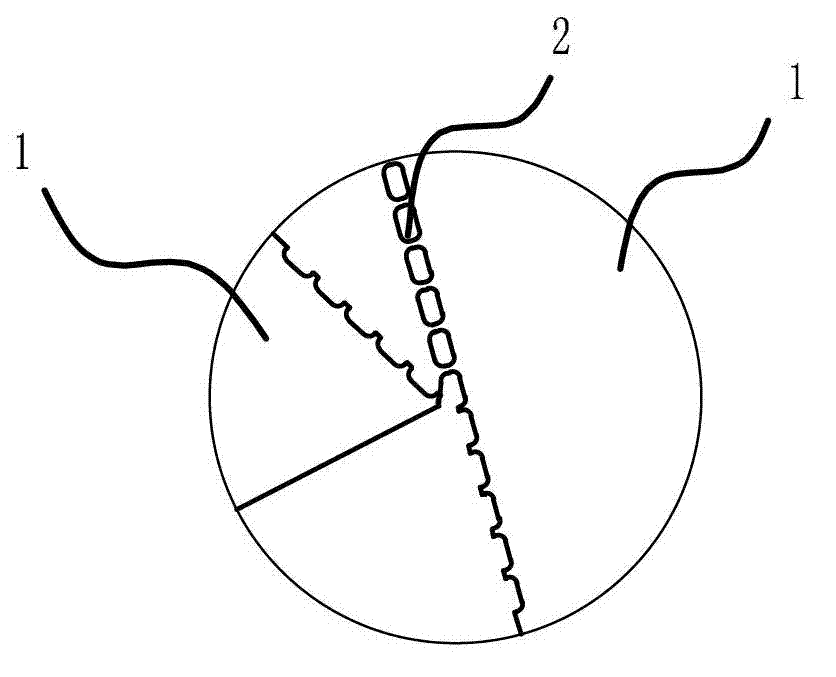

[0026] Such as figure 2 As shown, the opening slits 2 in this embodiment are elliptical holes arranged at intervals along a straight line. Of course, as ordinary engineers and technicians in the field, according to the technical inspiration of the present invention, it can be deduced without doubt that the opening seam 2 can also be a round hole, a tear line or a tear mark. The lines are slits arranged at intervals, and the tear marks are cuts or indentations that do not go through the mulch. The opening slit 2 is required to be able to meet the horizontal tensile force in the film width direction during the film covering process, and to ensure that the film will not be broken by the wind after film covering. The special fi...

Embodiment 2

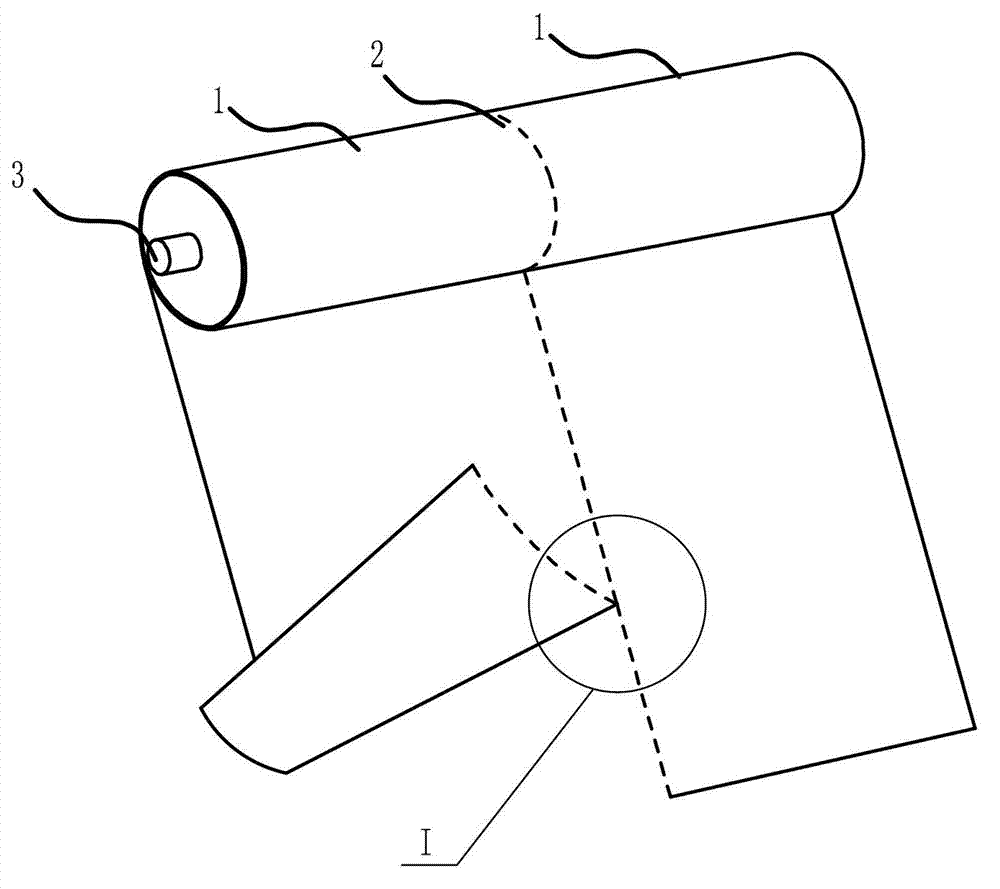

[0028] Embodiment two: if Figure 4 As shown, the plastic film of this embodiment is wound on the plastic film roller 3, and the plastic film can be uniformly made with two opening slits 2 along the longitudinal direction in the film making or film covering process according to the planting density of the crops. Of course, it can also be Make multiple opening seams 2 as required. In this embodiment, the opening seam 2 has tear lines arranged at a certain interval, and the tear lines are required to be able to meet the horizontal tension in the film width direction during the film covering process, and to ensure that they are not damaged by wind after film covering. blow out. The mulching film in this embodiment can be applied to crops covered by double rows, such as peanuts, garlic and other crops that need to be covered with a film to preserve moisture.

[0029] According to the technical inspiration of the above embodiments, the opening seam 2 of the present invention can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com