Novel cloth dust collector

A technology of dust collector and cloth bag, applied in the field of new type cloth bag dust collector, can solve the problems of reduced injection frequency and insufficient strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

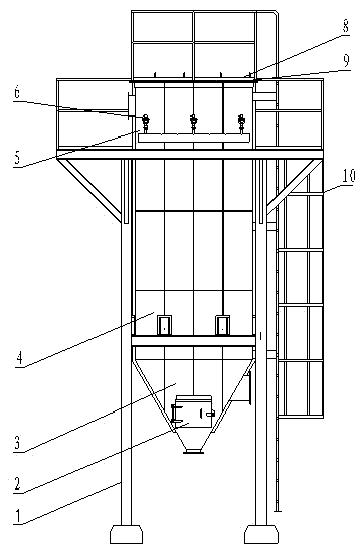

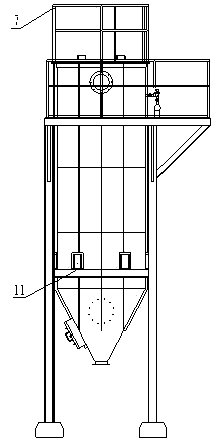

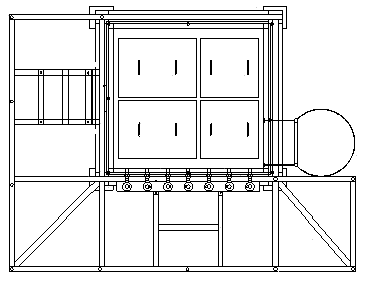

[0021] A new type of bag dust collector, as attached figure 1 and 2 As shown, it consists of a support frame 1, an inlet hole 2, a deflector 3, a casing 4, a porous plate 5, a pulse injection system 6, a top railing 7, a cover plate 8, a top cover surface 9, and a ladder 10; The upper end of the shell 4 is provided with a porous plate 5, one side of the porous plate 5 is provided with a rib plate, and 42 Φ162 through holes are provided on the porous plate, and a filter bag is provided on the lower side of the porous plate 5 Combination, the filter bag combination is composed of a filter bag and a cage head Venturi tube, the cage head Venturi tube is set on the top of the filter bag, and a plurality of cage longitudinal strips and upper and lower layers of cages are arranged on the inner wall of the filter bag The inner hoop is provided with a plurality of pulse injection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com