Enamel flat-bottom concentration reaction vessel

A reaction kettle and enamel technology, which is applied in the field of enamel flat bottom concentration reaction kettle, can solve the problems of high consumption of iron powder, slow reaction speed, hidden danger of pot overflow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in combination with specific embodiments.

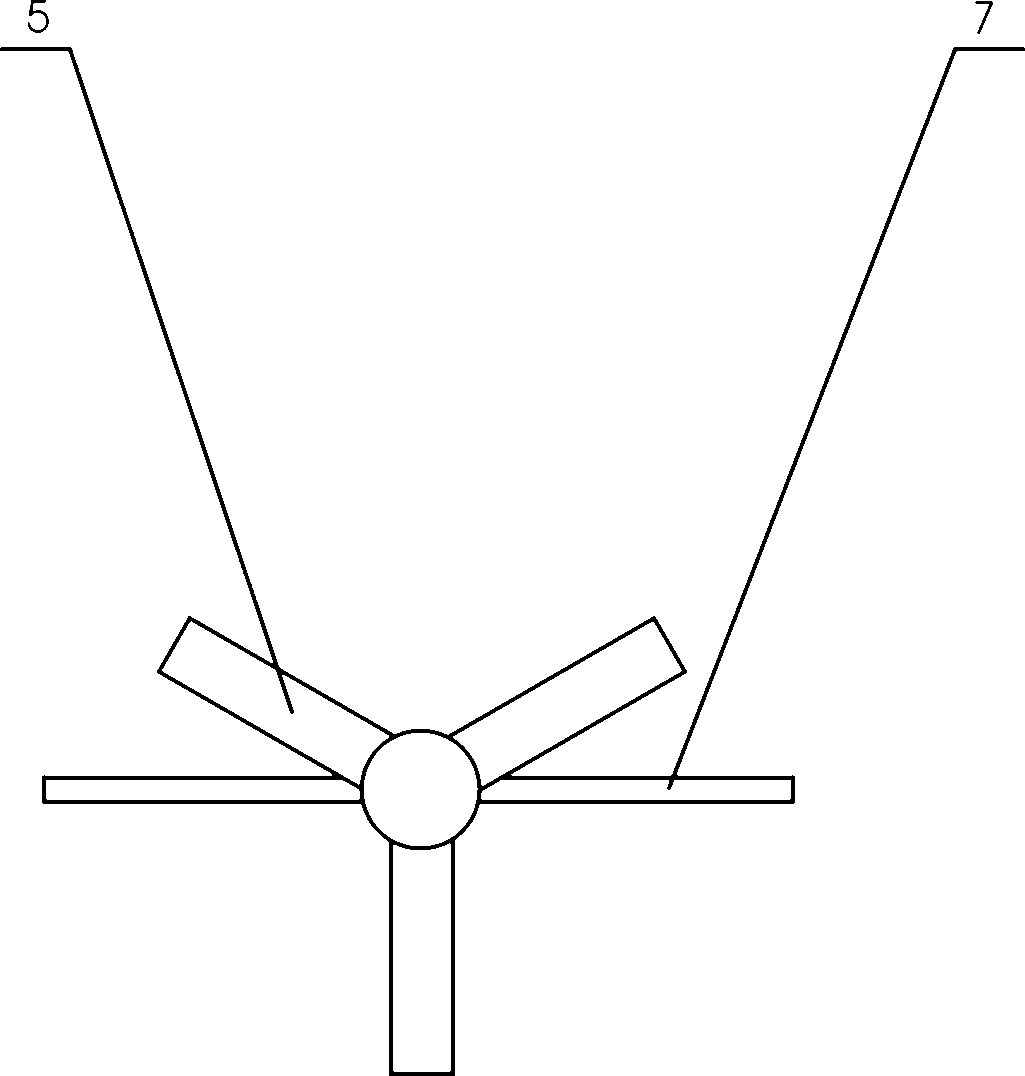

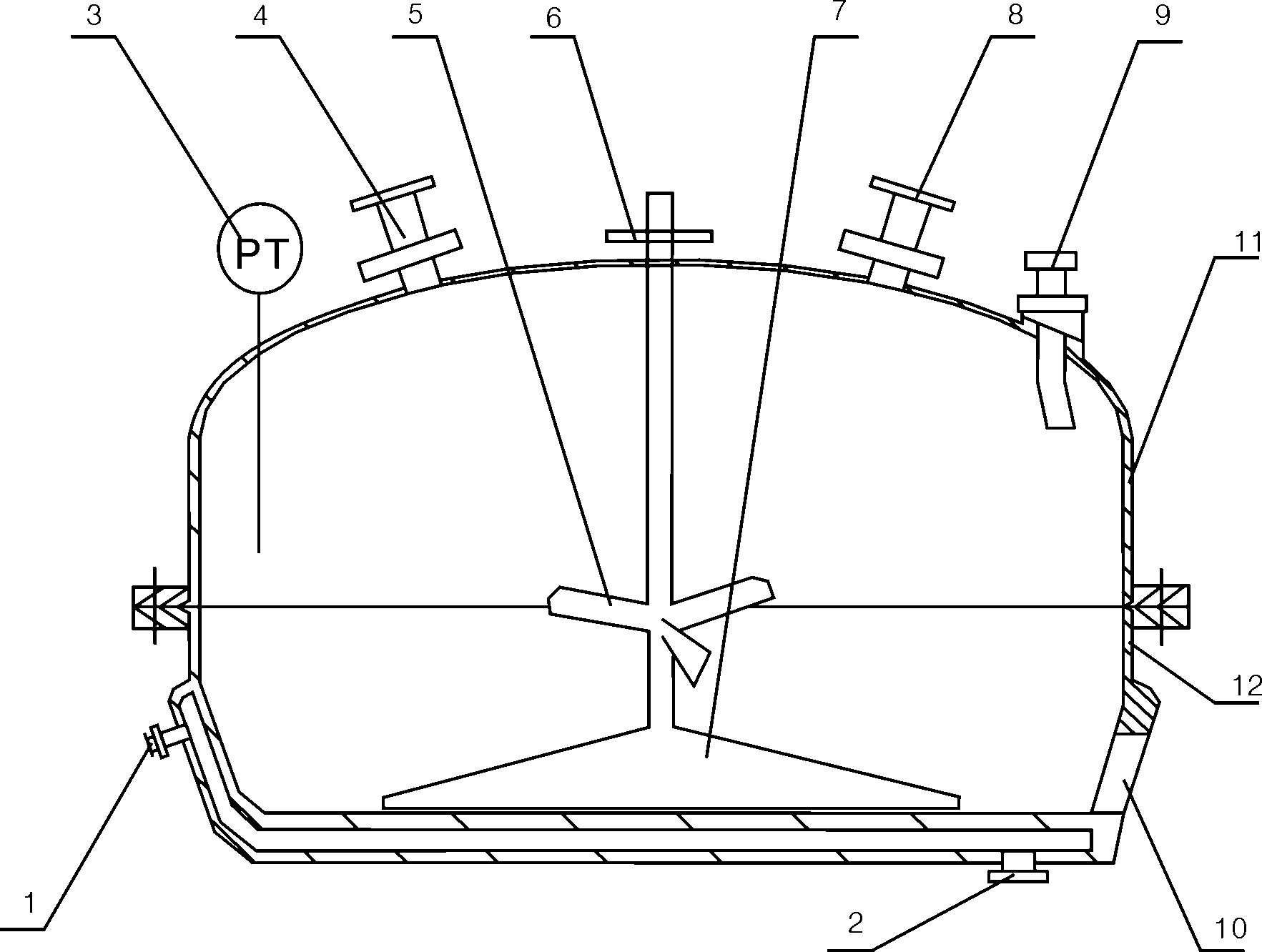

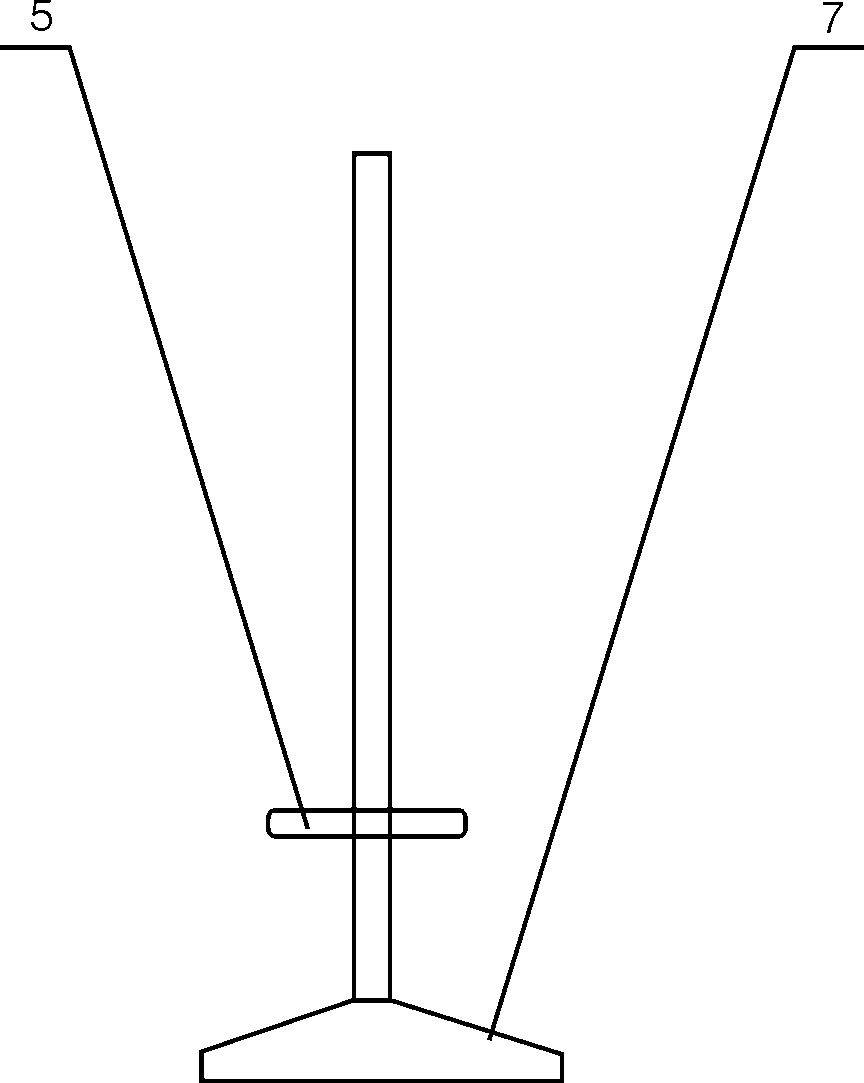

[0023] The reaction kettle for the production of aromatic amine and edible potassium iodide by reagent concentration and iron powder reduction method is characterized in that: the lid of the reaction kettle is a basin head cover, the stirring shaft is set in the middle of the reaction kettle, the bottom of the stirring shaft is equipped with a rake-type main paddle, and the rake-type main paddle is close to the stirring shaft The center is high and the end is low. The auxiliary stirring paddle is above the rake-type main paddle. The sub-stirring paddle is coaxial with the rake-type main paddle. The discharge port is located on the side of the kettle. , Paddle enamel, the bottom of the reactor is flat, and the bottom surface of the rake-type main paddle is parallel to the bottom of the reactor.

[0024] This enamel flat-bottomed concentration reaction kettle, the inner and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com