Injection molding mold for chain wheel of chain saw

A technology of injection molding and sprockets, which is applied in the field of injection molding molds for manufacturing chain saw sprockets, can solve problems such as low production efficiency, poor quality of parts, and impact on corporate benefits, so as to reduce production costs, improve production efficiency, and technology less demanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

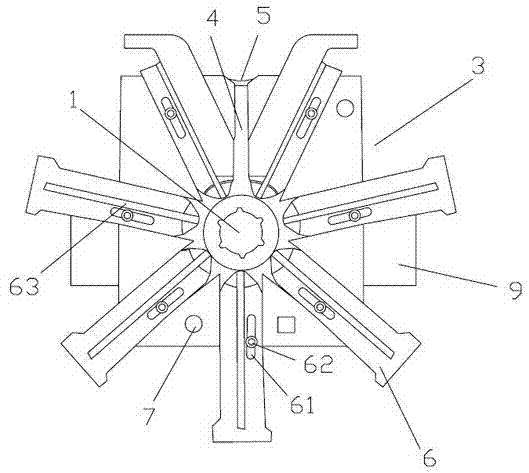

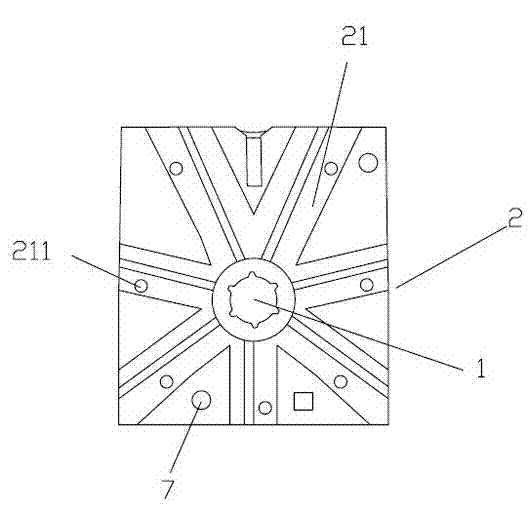

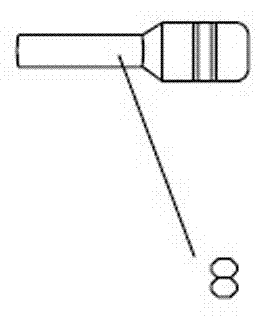

[0016] Such as Figure 1-3 As shown, the chain saw sprocket injection molding mold includes an upper mold 2 and a lower mold 3. Both the upper mold 2 and the lower mold 3 have fixing holes 7. The two molds are combined together and connected by fixing pins 8 inserted into the fixing holes 7. fixed. In order to guide the discharge of the gas inside the cavity, there are seven air guide pieces 6 around the cavity 1. The air guide pieces 6 are "T" shaped, and their ends are arc-shaped; Passage 63; the air guide plate 6 slides on the upper mold 2 through the cooperation of the chute 61 on the air guide plate 6 and the locking device 62, and the locking device 62 is a bolt. The lower mold 3 is provided with a groove 21 for matching with the air-guiding sheet 6, and also has a concave hole 211 for matching with a nut on the bolt on the groove 21. The liquid is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com