Concrete member molding machine

A molding machine and concrete technology, which is applied in the field of water collection well grate molding machine and concrete inspection manhole cover, can solve the problems of backward production technology, low production efficiency, and low degree of mechanization, so as to improve production efficiency, reduce work intensity, and liberate productivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

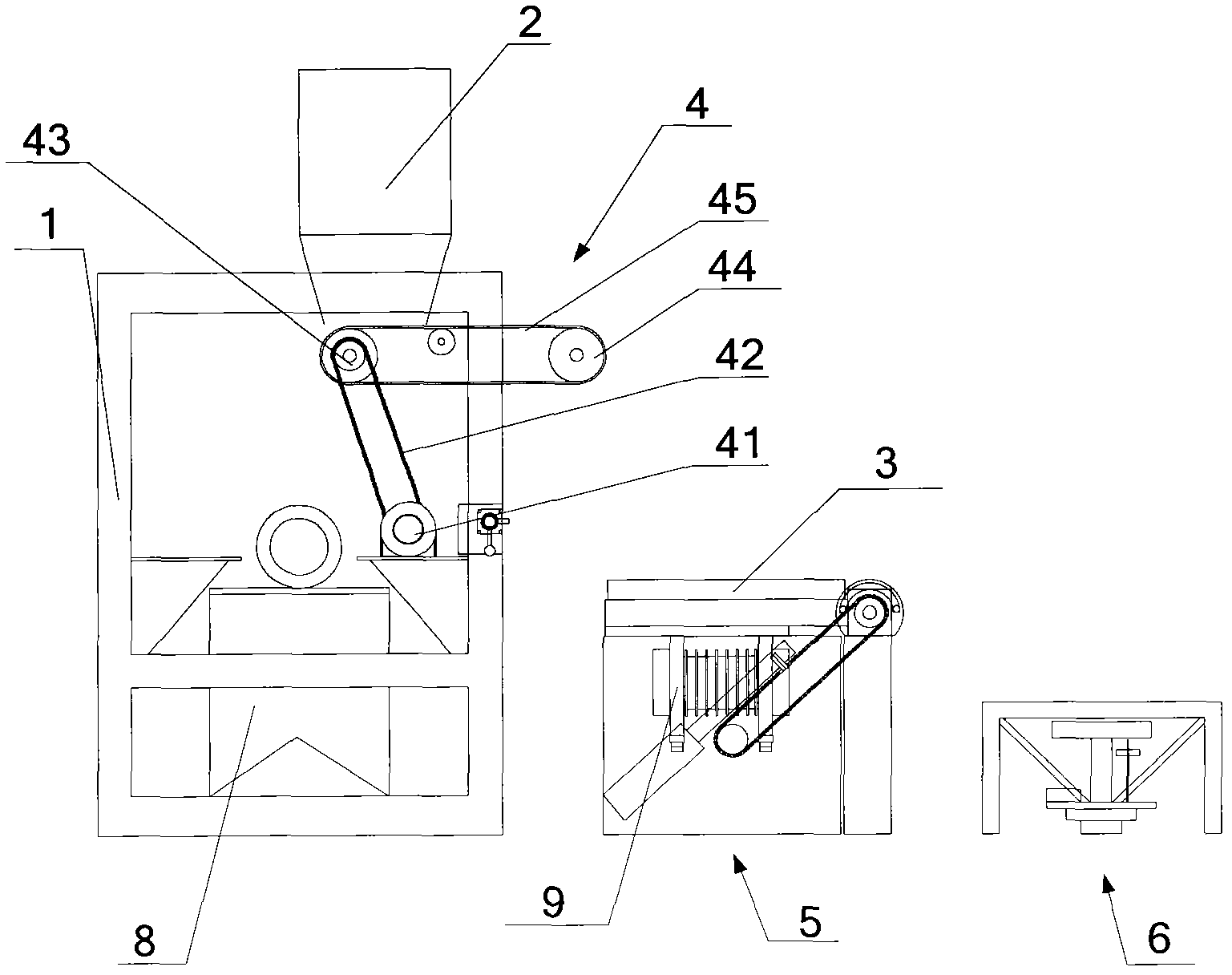

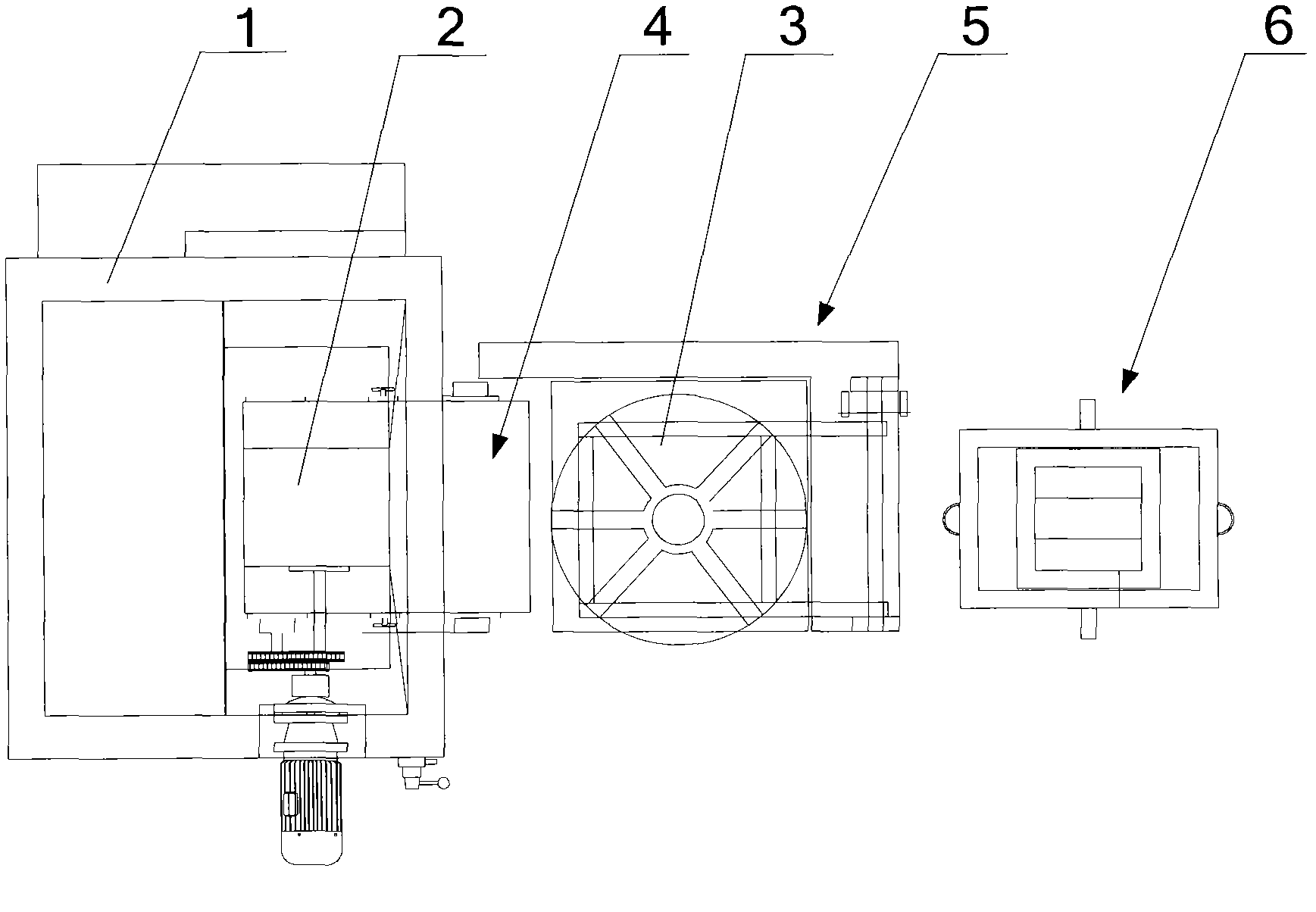

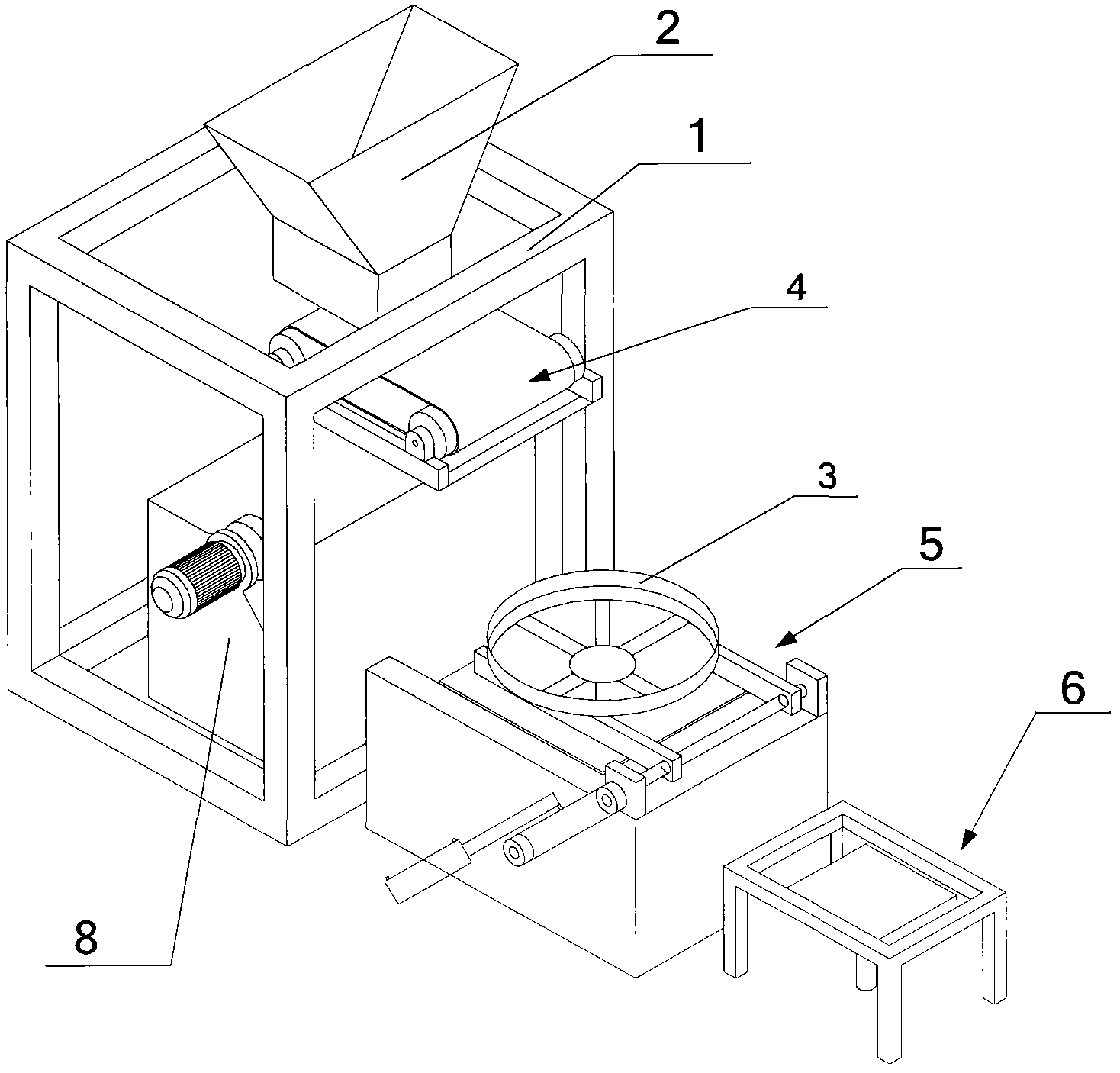

[0042] figure 1 It shows a schematic structural view of an embodiment of the concrete forming machine according to the present invention; figure 2 show figure 1 A schematic top view of the structure shown; image 3 show figure 1 A three-dimensional schematic diagram of the structure shown; Figure 4 It shows a schematic structural view of an embodiment of the rack according to the present invention; Figure 5shows a schematic structural view of an embodiment of the turning mechanism according to the present invention; Image 6 It shows a schematic structural view of an embodiment of the splicing machine according to the present invention; Figure 7 show Image 6 The three-dimensional schematic diagram of the bamboo plywood on the structure shown in ; Figure 8 A schematic structural view of an embodiment of the vibrating forming device according to the present invention is shown; Figure 9 shows the basis Figure 8 Schematic diagram of the front view of the structure...

Embodiment 2

[0061] Figure 11 It shows a schematic structural view of another embodiment of the concrete component molding machine according to the present invention; Figure 12 shows the basis Figure 11 A schematic top view of the structure shown; Figure 13 A schematic structural view of an embodiment of the palletizer according to the present invention is shown; Figure 14 show Figure 13 A schematic front view of the structure shown in .

[0062] like Figure 11 to Figure 16 As shown, this embodiment is basically the same as Embodiment 1, the difference is that:

[0063] It also includes a stacker 7 arranged on one side of the plate receiving machine 6, and the stacker 7 includes a stacker frame 71, a mobile frame 72, a slider 73, a slider lifting device and a mobile frame walking device, so The slider 73 is installed on the moving frame 72, and can move up and down along the moving frame 72 under the action of the slider lifting device, and the moving frame 72 is installed on ...

Embodiment 3

[0069] This embodiment is basically the same as the second embodiment, the difference is that: the lifting device of the slider and the traveling device of the mobile frame of the palletizer both adopt hydraulic cylinders.

[0070] like Figure 18 , Figure 19As shown, the stacker 7 includes a stacker frame 71, a mobile frame 72 slider 73, the slider lifting device can also be a slider lifting oil 76, and the mobile frame walking device can also be a mobile frame walking Oil cylinder 77, described moving frame 72 is installed on the described stacker frame 71, and one end of described stacker frame 71 is fixed on the described frame 1, and one end of described moving frame walking oil cylinder 77 is fixed on the described On the frame 1, the other end is fixed on the moving frame 72, and the moving frame 72 can move linearly along the chute 711 of the stacker frame 71 under the action of the moving frame walking cylinder 77; Slide block lift cylinder 76 and slide block 73 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com