Micropore rubber pad and manufacture process thereof

A technology of microporous rubber and backing plate, which is applied in the field of polymer processing, can solve the problems of poor impact load resistance, heavy weight of solid rubber backing plate, and low cushioning and shock absorption performance, and achieve strong impact load resistance and texture Uniform, high cushioning and shock absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] A microporous rubber backing plate, the backing plate is made of the following ingredients in proportion by weight: 100 parts of Jihua EPDM4045, 10 parts of ZnO, 1 part of stearic acid 800 type, 1.2 parts of accelerator CBS, 0.8 parts of accelerator TMTD, 2 parts of S-80 vulcanizing agent, 65 parts of carbon black N330, 5 parts of nano clay, 25 parts of paraffin oil, 1 part of anti-aging agent RD, 1 part of anti-aging agent 4010NA, Rhine powder A- 16 is 2 copies, OBSH is 2 copies;

[0036] Above-mentioned microporous rubber backing plate is made by following preparation method:

[0037] a. Take each component according to the above-mentioned formula quantity, and set aside;

[0038] b. Put Jihua EPDM4045 into the internal mixing chamber of the internal mixer and pressurize (6-7MPa) for internal mixing for 1 minute, the internal mixing temperature is 45-50°C; the internal mixer speed is 35r / min;

[0039] c. Then put ZnO, stearic acid type 800, anti-aging agent 4010NA, ...

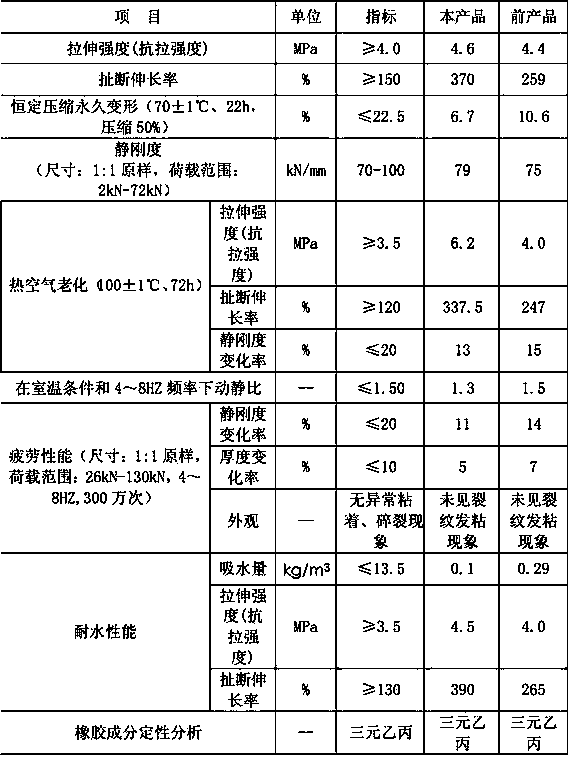

PUM

| Property | Measurement | Unit |

|---|---|---|

| stiffness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com