Method for evaluating high-temperature softening-melting dropping properties of iron-bearing burden

An evaluation method, reflow technology, applied in the direction of furnace, blast furnace, furnace type, etc., can solve the problem of not enough to reflect the actual situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

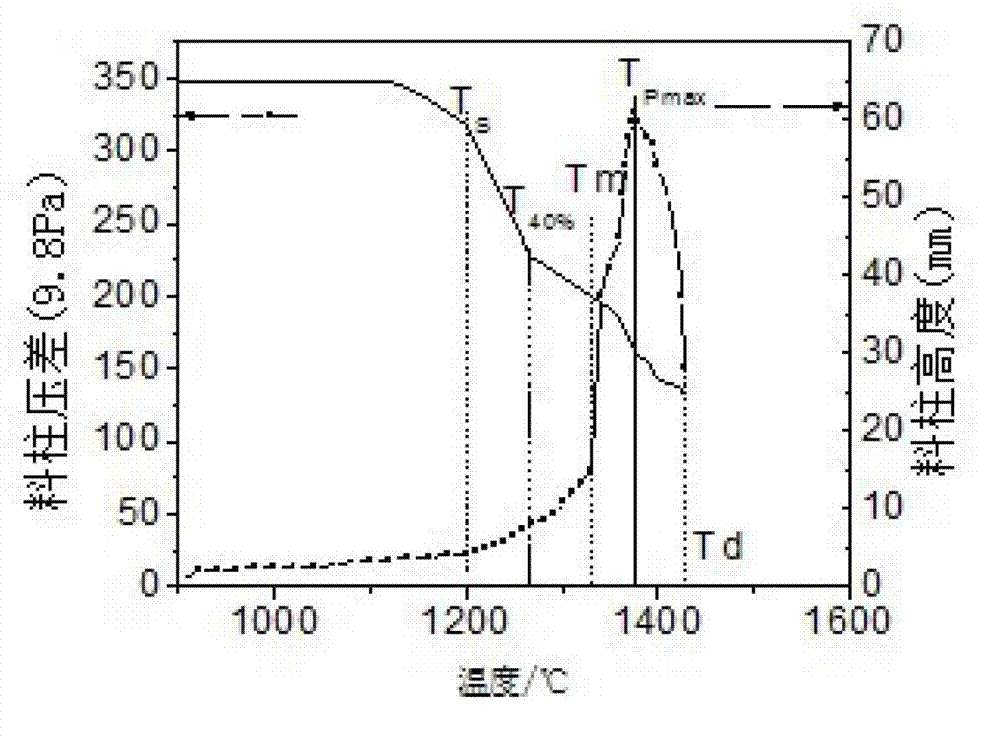

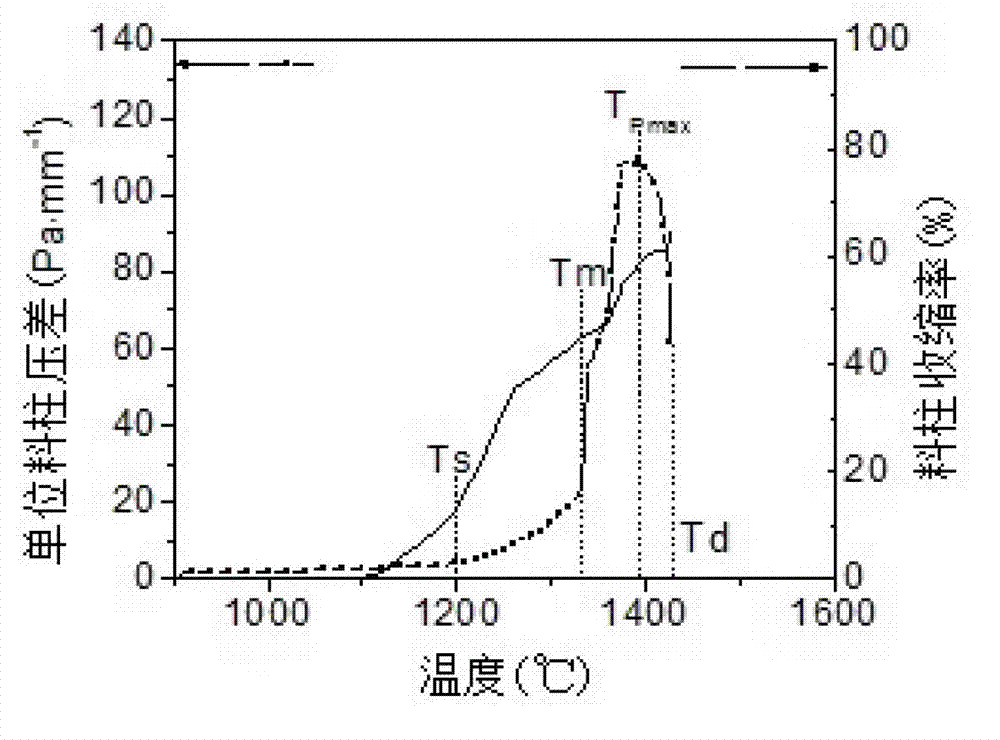

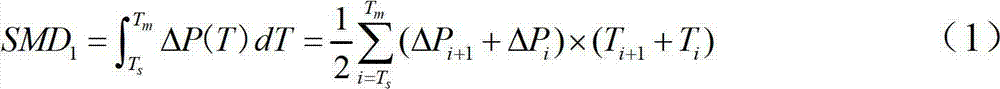

[0032] Put the iron-containing charge and coke into the graphite reaction tube in such a way that the bottom and top layers of the material column are respectively 20g of coke, and the middle layer is the iron-containing charge, and the load of the material column is 1kg / cm 2 , start the drop test according to the conditions in Table 1. When the molten iron drops to the crucible at the bottom of the corundum tube, turn off the power and cool down to room temperature, and the test ends. The temperature, material column height and material column pressure difference during the test are monitored and recorded by the computer in real time.

[0033] Table 1 Drop test conditions for iron-containing charge

[0034]

[0035] Table 2 Evaluation comparison of reflow dripping characteristics of typical comprehensive charge

[0036]

[0037]

[0038]

[0039] The comprehensive furnace material used in the on-site production of a steel factory was subjected to a reflow drippin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com