Submersible electric pump with intermediate bearing as main stress bearing

A technology for intermediate bearings and submersible electric pumps, which is applied to components, pumps, pump devices, etc. of pumping devices for elastic fluids, and can solve the problem that the bottom bearing seat is easy to fall off and damage, which affects the reliability of the motor cavity seal, and electric pumps Reduced operating accuracy and other issues, to achieve significant energy-saving effects, strengthen rigidity, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

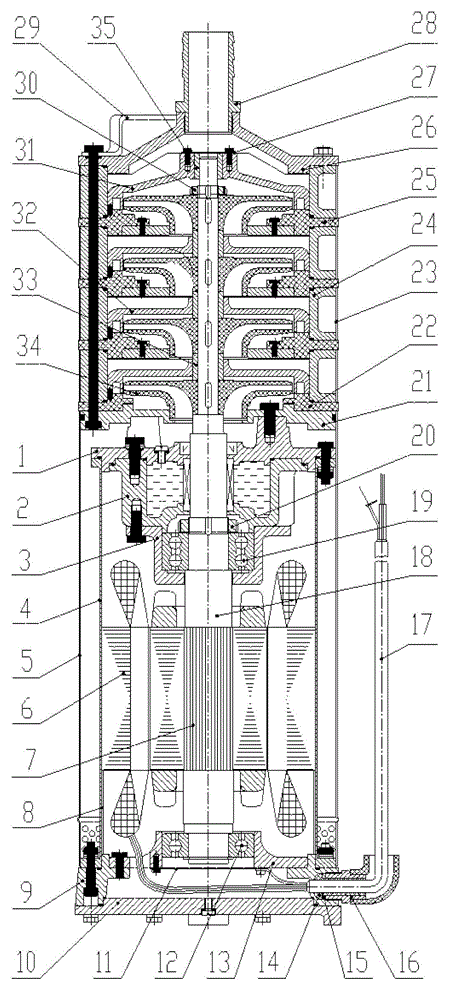

[0034] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

[0035] Such as figure 1 As shown, a submersible electric pump in which an intermediate bearing of the present invention is a stressed main bearing is mainly composed of a motor, a pump, and an outer shell 5. The motor is placed in the outer shell 5, and the pump is placed between the motor and the outer shell 5. Above, a water inlet hole is provided on the wall of the lower end of the outer casing 5, and an annular channel for passing water is provided between the motor casing 4 and the outer casing 5. The pump consists of a water pump upper cover 26, a water pump lower cover 21 and It is composed of the impeller 34 surrounded by the guide vane casing 23, the guide vane 32, the guide vane cylinder 24, the final guide vane 31, the spacer 33, the partition 25, and the backing plate 22. Ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com