Hydraulic retarder with pressure power generation device and control method thereof

A technology of hydraulic retarder and pressure power generation, which is applied to piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, liquid resistance brakes, etc. Energy has not been recycled and other problems, to achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

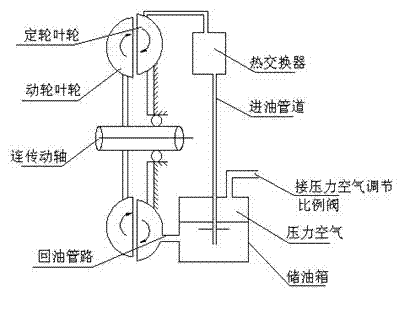

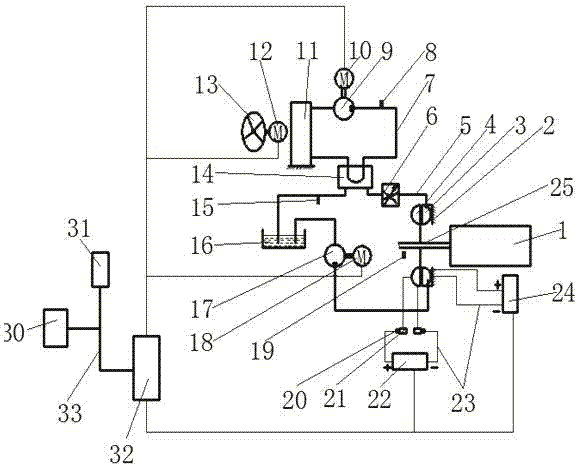

[0025] image 3 As shown, the structure of the hydraulic retarder with pressure generating device of the present invention includes a retarder body, a heat dissipation system, a pressure generating device, an electronic control system and other parts. The hydraulic retarder can be arranged at the output end of the transmission, the input end of the transmission and the input end of the rear axle as required. Here, the arrangement at the output end of the transmission is taken as an example for description.

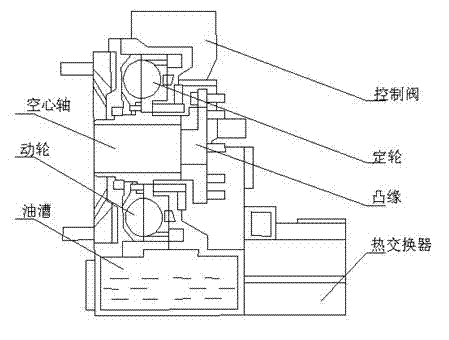

[0026] The retarder body includes a moving wheel 3, a fixed wheel 4, a retarder housing 2, an oil pump 17, an oil pump driving motor 18, a working fluid storage tank 16, a throttle valve 6, and the like. The moving wheel 3 and the fixed wheel 4 are coaxially opposed with a gap, and the gap between the moving wheel 3 and the fixed wheel 4 forms a sealed working chamber. The oil inlet and liquid outlet are opened on the working chamber, and the fixed wheel 4 is fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com