Undamaged detection method for pipeline

A non-destructive testing, pipeline technology, applied in the field of image processing and pattern recognition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

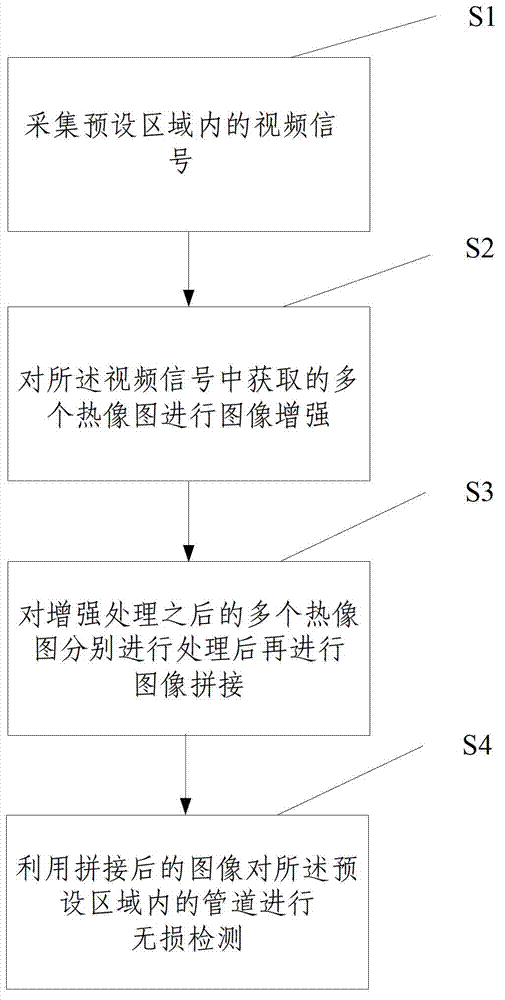

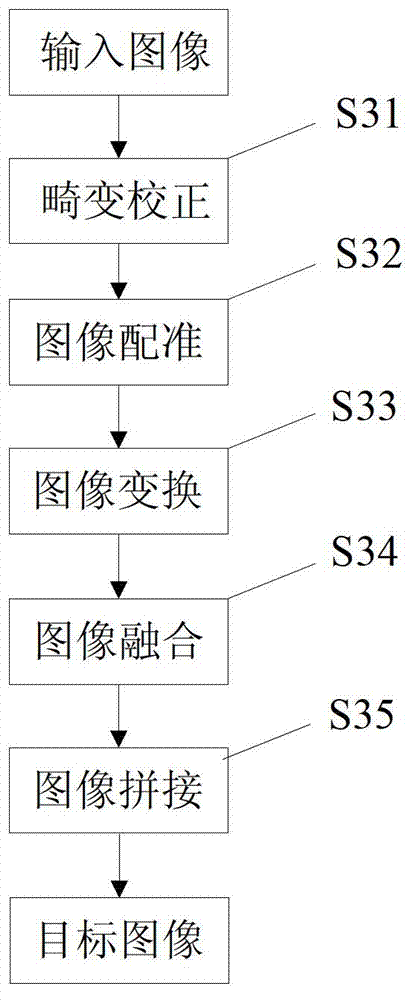

[0044] The present invention designs a systematic and comprehensive non-destructive testing method for various types of pipelines in public pipeline corridors in chemical industry parks. The pipelines in public pipeline corridors are long in length and high in height, and online monitoring is difficult to provide panoramic detection results of pipelines. Thermal imaging of pipelines is required. Graph splicing technology research. Infrared images are gray-scale images without color or shadows, so for the human eye, the resolution is low and there is no stereoscopic effect; due to thermal balance of the scene, long wavelength of light waves, long transmission distance and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com