In-situ indentation/scratch testing device

A scratch test, in-situ technology, applied in the direction of testing material hardness, etc., can solve the problems of nano-indentation and scratch test device development and research are few, hindering development, etc., to achieve compact structure, high positioning accuracy, quality light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

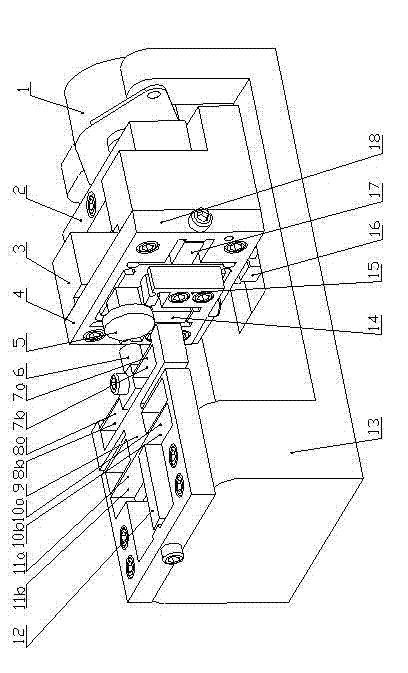

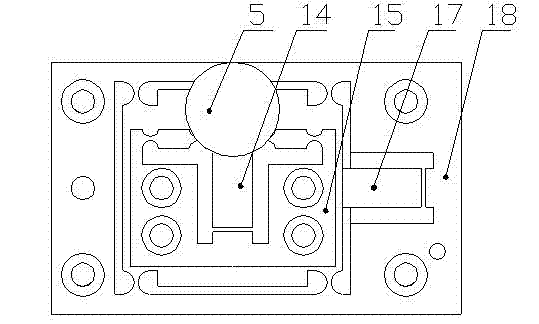

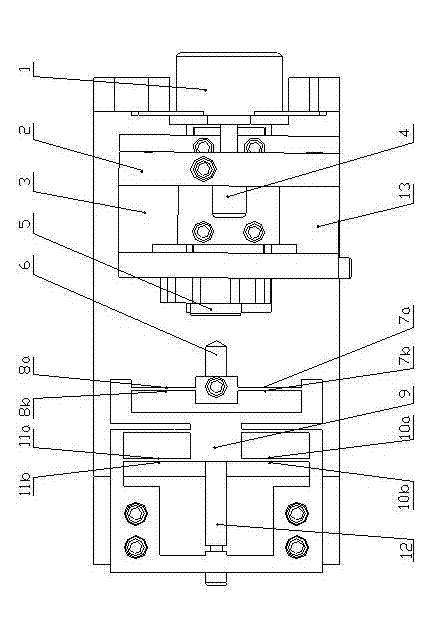

[0021] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0022] see figure 1 , the in-situ pressure / scratch testing device of the present invention includes a precision positioning platform in X and Y directions, a precision linear positioning platform in Z direction, a precision pressing drive unit, a load signal detection and a displacement signal detection unit, wherein the X, The precision positioning platform in the Y direction is fixed on the base 13 through the connecting plate II3, and the stage 5 is connected with the precision positioning platform in the X and Y directions through the piezoelectric stacks 17 and 14 in the X and Y directions. The piezoelectric stacks 17 and 14 in the X and Y directions on the precision positioning platform are directly driven to realize precise movement in the X and Y directions. The diamond indenter 6 is fixedly connected wit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap