Method for determining vanadium in silicon-vanadium alloy

A technology of silicon-vanadium alloy and determination method, which is applied in the field of analytical chemistry and can solve problems such as analysis deviation of vanadium content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

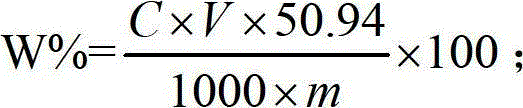

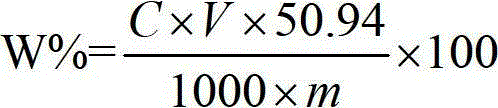

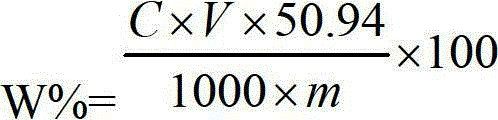

Image

Examples

Embodiment 1

[0025] Weigh 0.1500g of silicon-vanadium alloy standard sample (model SL25--09) and place it in a 500mL conical flask, add about 10ml of water to wet the sample, add 10ml of concentrated nitric acid, 5ml of concentrated hydrochloric acid and 5ml of hydrofluoric acid , Dissolve the sample at room temperature, then add 40ml of sulfuric acid (1:1) and place it on an electric furnace to heat until the sample is completely dissolved and evaporated until sulfuric acid fumes are emitted for 2-3 minutes Take it off, cool down, add 10ml of phosphoric acid (1:1) and 80ml of water, heat to dissolve the salt, remove from the boil and cool to room temperature;

[0026] Add 5 ml of ammonium ferrous sulfate to the sample and mix well, directly add potassium permanganate solution dropwise until the solution appears purple-red after shaking and does not disappear, and excessive 1-2 drops shake fully and let stand for 5 minutes, add 1 g of urea, Then add sodium nitrite solution dropwise until t...

Embodiment 2

[0030] Example 2: Weigh 0.1500g silicon-vanadium alloy standard sample (model SL25--09) and adopt the test method of Example 1. The difference from Example 1 is that no hydrofluoric acid is added. The obtained results are shown in Table 1.

Embodiment 3

[0031] Example 3: Weigh 0.1500g of silicon-vanadium alloy 1# sample and test it by the method of Example 1, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com