Experimental facility for testing autoignition temperature of gas in high-pressure oxygen-enriched environment

An experimental device and auto-ignition temperature technology, applied in the investigation stage/state change, etc., can solve the problems of undesigned test device and inability to complete auto-ignition temperature measurement, etc., and achieve the effect of increasing the measurement range, reducing risk, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention tests the behavior of spontaneous combustion of the gas under airtight condition and pre-set pressure by continuously raising the temperature, and records the temperature change in the whole process through the temperature and pressure sensor and the computer.

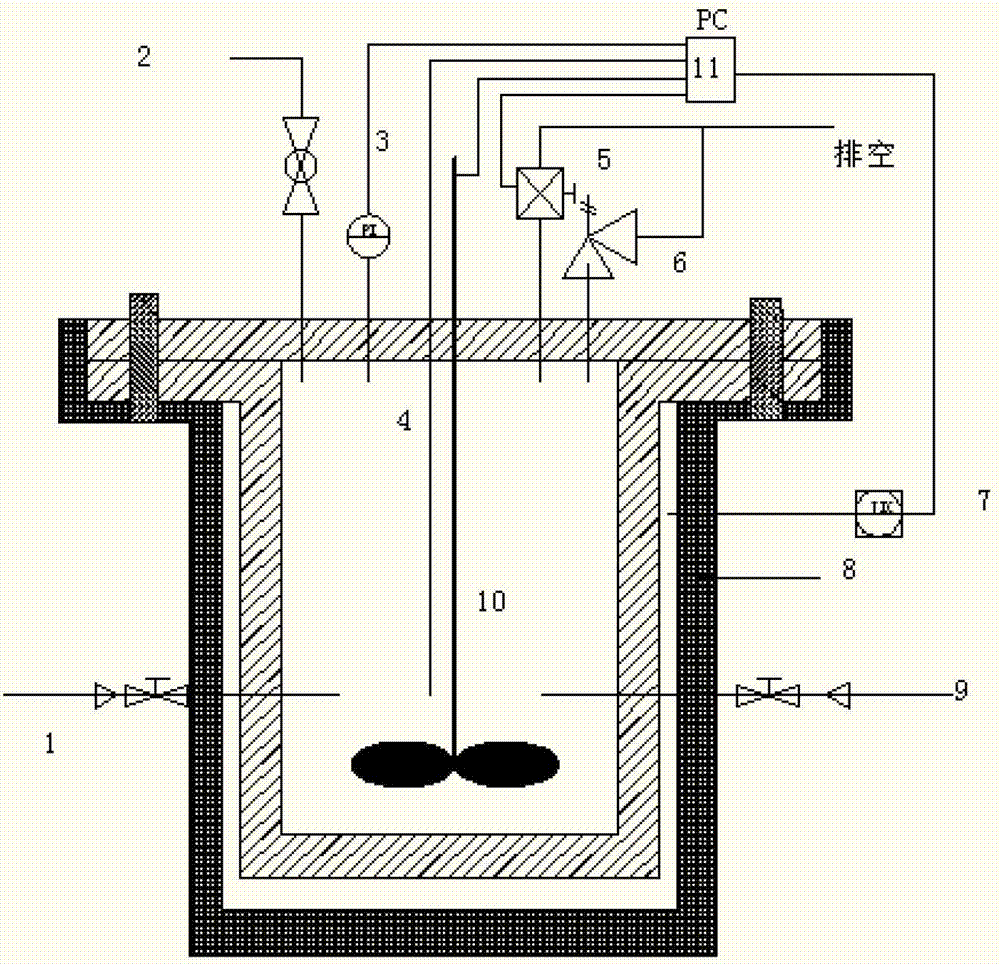

[0026] The experimental device includes a gas supply part, a temperature-controlled heating part, a reactor part, a safety interlock device and a PC, wherein,

[0027] The gas supply part includes a steel cylinder containing air or oxygen-enriched air, a steel cylinder containing the gas to be measured, a one-way valve and a needle valve, and the air or oxygen-enriched air passes through the steel cylinder, and is reacted The middle and lower part of the cylinder of the reactor part enters the reactor part, and the gas to be tested enters the reactor part from the middle and lower part of the cylinder of the reactor part through the steel cylinder through the one-way valve and the needle val...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com