Smoke composite analysis system and method

An analysis system and flue gas technology, applied in the analysis of materials, particle suspension analysis, suspension and porous material analysis, etc., can solve the problem that the diameter of the sampling pipe cannot be changed, cannot have sharp angles, and can only be smoothly bent, etc. Achieve the effects of good immediacy, reduced monitoring costs, and expanded scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A flue gas composite analysis system, comprising:

[0052] A sampling unit, the sampling unit includes at least a first sampling pipeline and a second sampling pipeline;

[0053] A flow path switching unit, the flow path switching unit includes an input pipeline and a moving module, the input pipeline is arranged on the moving module, and the flow path switching unit is connected to the sampling unit;

[0054] a control unit, the control unit controls the movement of the mobile module, so that the input pipeline is selectively communicated with the first sampling pipeline or the second sampling pipeline;

[0055] A detection and analysis unit, the detection and analysis unit analyzes the information of the sample input through the input pipeline and obtained through sampling by the sampling unit.

[0056]Further, when the input pipeline selectively communicates with the first sampling pipeline, the control unit controls the gas purge gas pipeline passing through the fi...

Embodiment 2

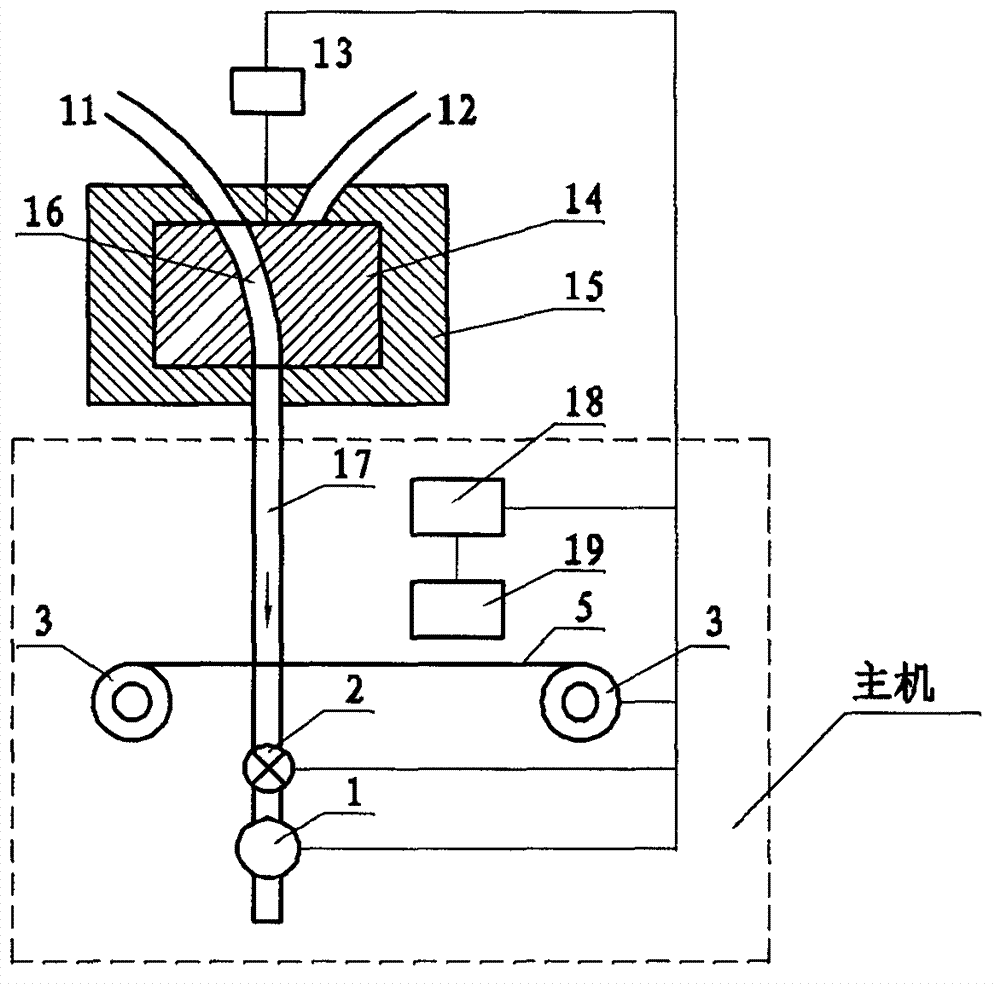

[0071] see figure 1 , a flue gas composite analysis system, applied to waste incineration plants, comprising: a sampling unit, a filter membrane 5, a filter membrane moving unit 3, a flow path switching unit 15, a control unit 18 and a detection analysis unit 19;

[0072] 1. The sampling unit includes an air pump 1, a flow control module 2, a first sampling pipeline 11, a second sampling pipeline 12, and a common pipeline 17;

[0073] The air suction pump 1 collects gas into the flow path at a certain flow rate. The flow control module 2 of the sampling unit is connected to the control unit 18 so that the control unit 18 can monitor and control the working state of the flow control module 2 .

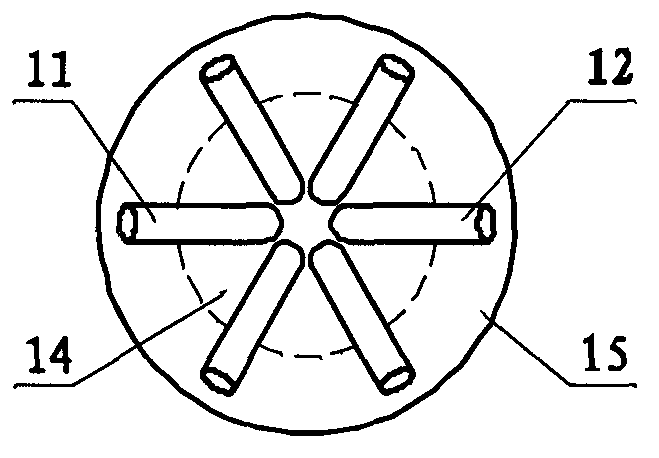

[0074] 2. The flow path switching unit 15 includes a mobile module 14 and an input pipeline 16. The mobile module 14 can make the input pipeline 16 connect with the first sampling pipeline 11 and the second sampling pipeline under the control of the control unit 18, respectively. 12 c...

Embodiment 3

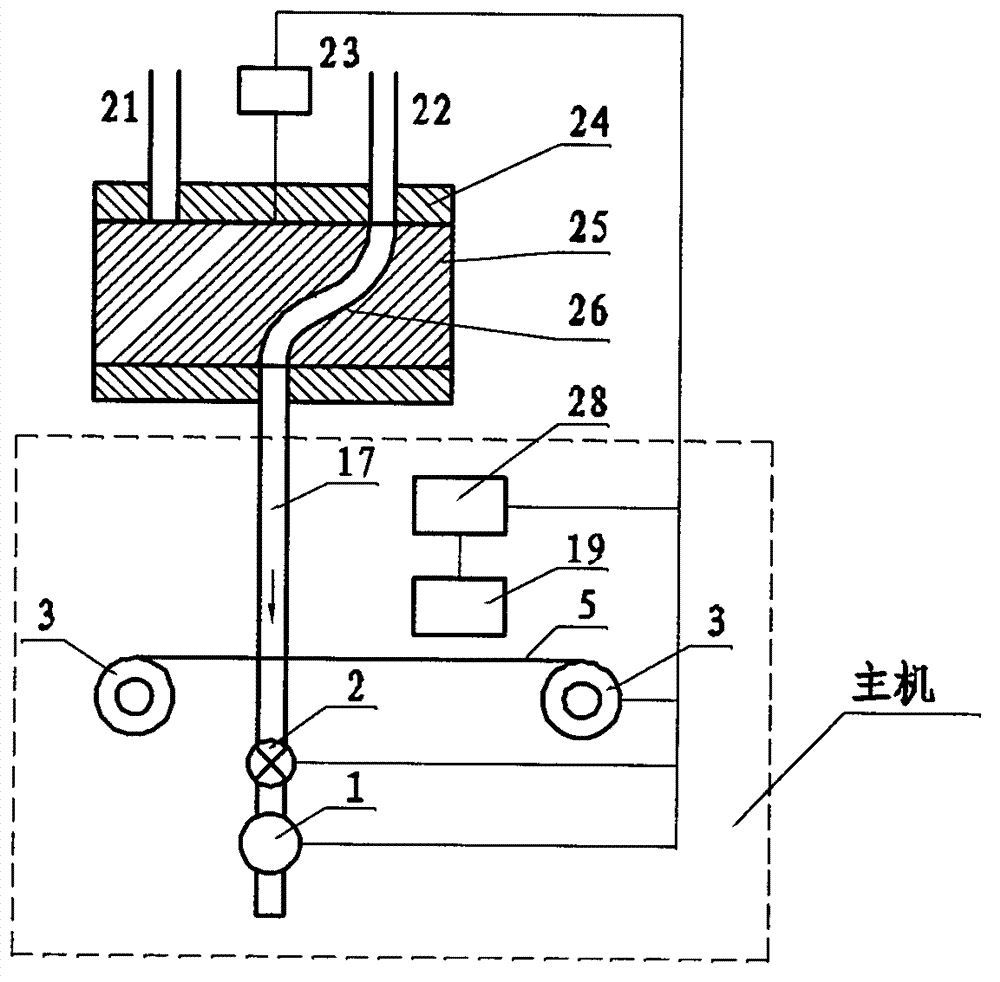

[0101] see image 3 , Figure 4 , a flue gas compound analysis system, different from the analysis system described in embodiment 1 is:

[0102] The flue gas composite analysis system of this embodiment is applied to a smelter.

[0103] Here, the ratio of the radius of curvature of the bend of the feed line 26 to the radius of the bend is 1.5. It can ensure that the particle loss here does not exceed 15% set according to the working conditions.

[0104] The moving module 24 of this embodiment rotates through the flow channel switching unit 25 .

[0105] This embodiment also provides a kind of composite analysis method for flue gas, which is different from the analysis method described in Example 1 in that:

[0106] 1. In step A, the flue gas composite analysis system of this embodiment is used.

[0107] 2. Step B also includes a purging step: when the input pipeline 26 is selectively communicated with the first sampling pipeline 21, the control unit 28 controls the gas pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com