Method for removing sulfur trioxide in production of heavy alkyl benzene sulfonic acid

A technology of heavy alkyl benzene sulfonic acid and alkyl benzene sulfonic acid material, applied in the field of heavy alkyl benzene sulfonate production, can solve the problem of affecting the quality of heavy alkyl benzene sulfonate, affecting the health of packaging workers, and environmental protection costs and high economic cost, to achieve the effect of stable deacidification, occupational health protection, and acid content reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

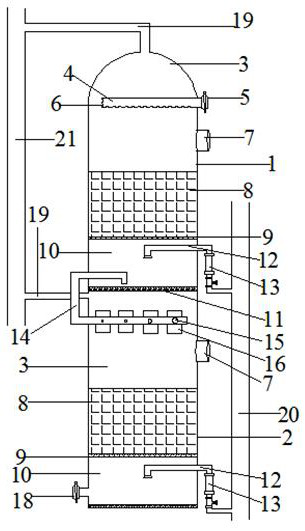

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0025] A method for removing sulfur trioxide in the production of heavy alkylbenzenesulfonic acid is completed by the following devices and methods:

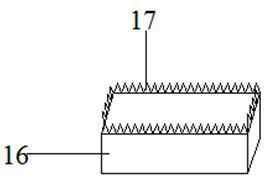

[0026] Removal device: such as Figure 1-2 As shown, it includes a first removal unit 1 and a second removal unit 2 separated by a separation plate 11, and the first removal unit 1 and the second removal unit 2 are sequentially provided with a feed liquid distribution chamber 3, a Pall ring packing layer 8, liquid storage chamber 10, a filter screen 9 is arranged between the liquid storage chamber 10 and the Pall ring packing layer 8, and the Pall ring packing layer 8 is arranged on the filter screen 9, and the Pall ring packing layer 8 can make The heavy alkylbenzene sulfonic acid feed liquid and waste heat air are fully dispersed in the removal unit, and the flow velocity of the heavy alkyl benzene sulfonic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com