Treatment method for arsenic-alkali residue

A treatment method, the technology of arsenic-alkali slag, applied in the field of hydrometallurgy, can solve the problems of unstable leaching effect, difficult industrial application, and difficult solid-liquid separation, and achieve the effect of low difficulty of solid-liquid separation and reduction of the proportion of fine particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

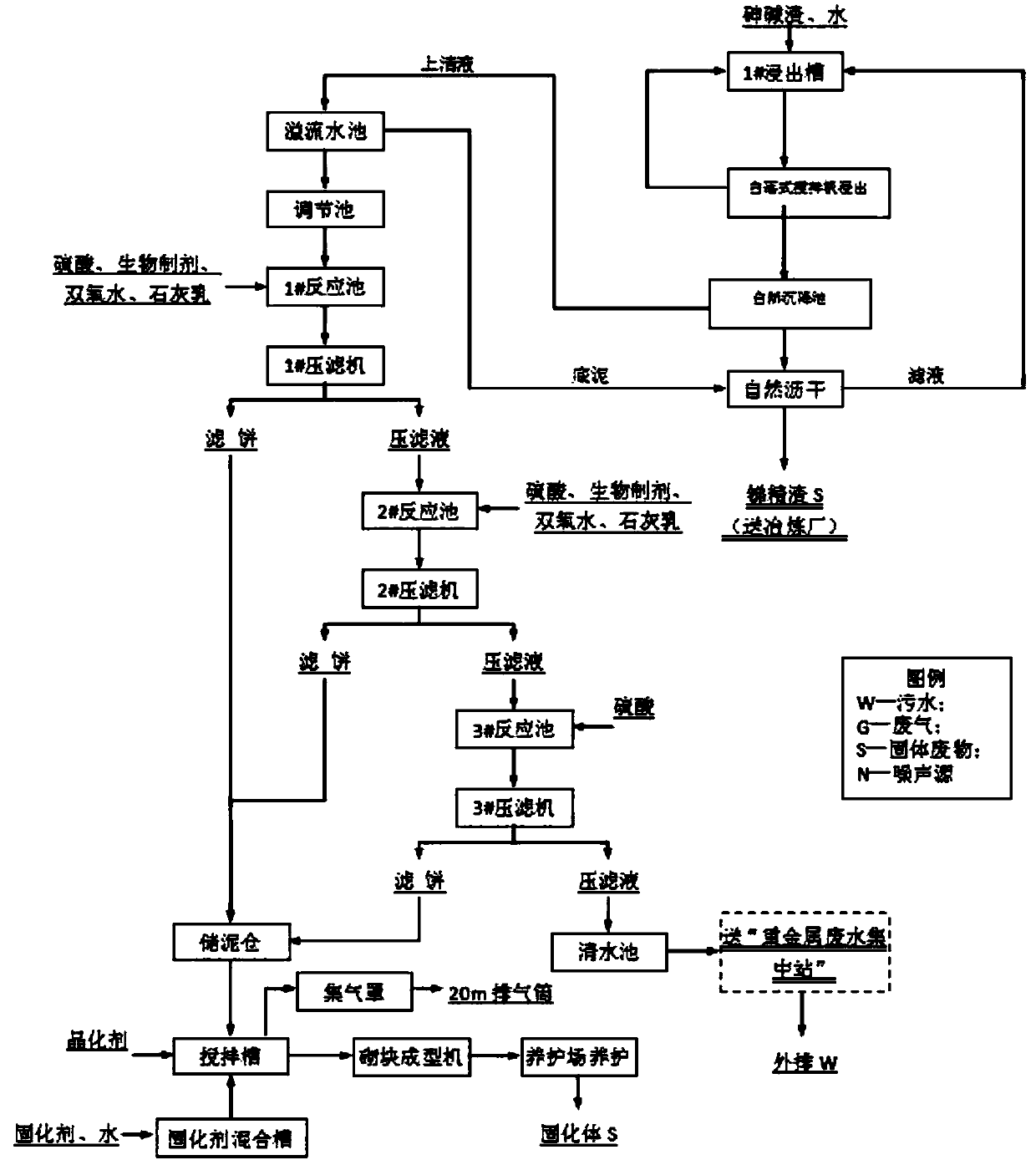

Method used

Image

Examples

Embodiment 1

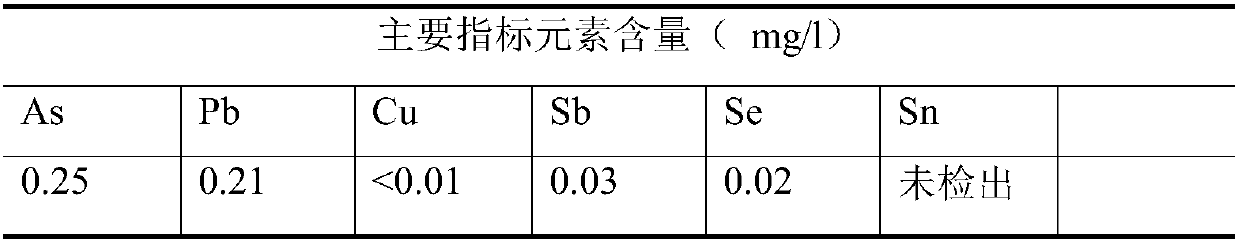

[0081] Weigh 100kg of arsenic-alkali slag containing 16.10% of arsenic and 22.99% of antimony, add 150kg of water to soak for 68 hours, put it into a self-falling concrete mixer and add 250kg of water to stir at a temperature of about 25°C (stirring speed is 15-18r / min ) to react for 1 hour. Then after natural precipitation, the supernatant was taken out, and the antimony fine slag at the bottom was naturally air-dried. The dry weight of the slag was 32kg. The grades of antimony and arsenic in the analysis slag were: antimony 70.0%, arsenic 1.4%, and the calculation shows that the recovery rate of antimony reached 97.4%. %, the leaching rate of arsenic reaches 97.2%.

Embodiment 2

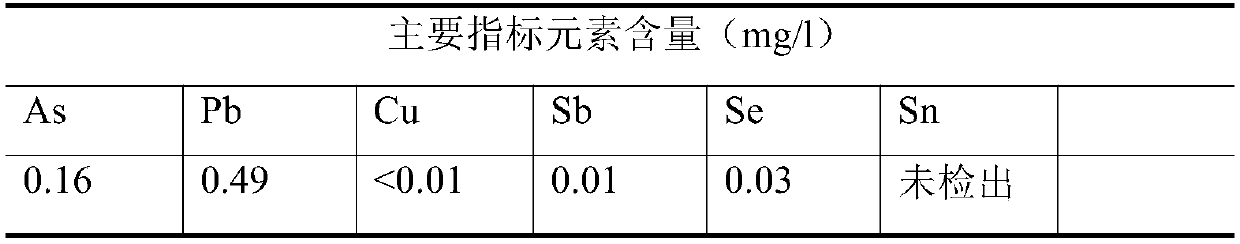

[0083]Weigh 100kg of arsenic-alkali slag containing 16.10% of arsenic and 22.99% of antimony, add 150kg of water to soak for 72 hours, put it into a self-falling concrete mixer and add 250kg of water to stir at a temperature of about 25°C (stirring speed is 15-18r / min ) to react for 1 hour. After natural precipitation, the supernatant was taken out, and the antimony fine residue at the bottom was naturally air-dried. The dry weight of the residue was 29kg. The grades of antimony and arsenic in the residue were analyzed, and they were respectively: antimony 77.9%, arsenic 1.3%, and the calculation showed that the recovery rate of antimony reached 98.26%. %, the leaching rate of arsenic reaches 97.66%.

Embodiment 3

[0085] Weigh 100kg of arsenic-alkali slag containing 16.10% of arsenic and 22.99% of antimony, put it into a self-falling concrete mixer and add 400kg of water for stirring (stirring speed is 15-18r / min) and react for 1 hour. After natural precipitation, the supernatant was taken out, and the antimony fine residue at the bottom was naturally air-dried. The dry weight of the residue was 34kg. The grades of antimony and arsenic in the analysis residue were: antimony 61%, arsenic 2.9%, and the calculation showed that the recovery rate of antimony reached 90.21%. %, the leaching rate of arsenic reaches 93.88%. The arsenic-alkali slag was not pre-soaked, and the leaching rate was slightly worse than that of Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com