Automatic leveling control device based on single chip microcomputer (SCM)

A single-chip control, automatic leveling technology, applied in the direction of computer control, feedback control, program control, etc., can solve the problems of unguaranteed leveling speed and accuracy, long time consumption, low precision, etc., to reduce work The effect of low burden, small space required for installation, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

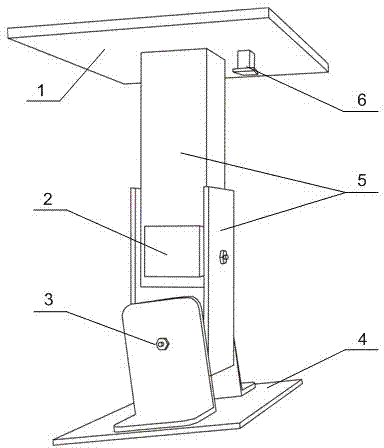

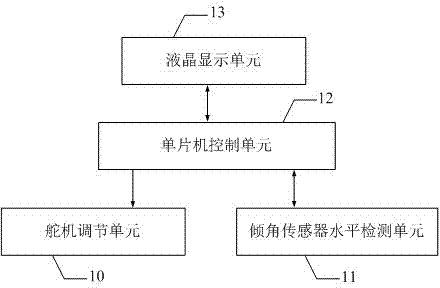

[0025] Embodiment 1: A kind of automatic leveling control device based on single-chip microcomputer provided by the present invention, its structure is as follows figure 1 , shown in 2, includes equipment part and automatic control part, and described equipment part is provided with loading platform 1, X axial steering gear 2, Y axial steering gear 3, base 4, X, Y axial rotation mechanism 5 and the three-axis acceleration sensor 6, on the base 4, the X, Y axial rotation mechanism 5 is installed, and the X axial steering gear 2 and the Y axial steering gear 3 are installed on the X, Y axial steering gear with two axes perpendicular to each other. On the Y-axis rotation mechanism 5, the rotation axes of the X-axis steering gear 2 and the Y-axis steering gear 3 are perpendicular to each other, and the X-axis steering gear and the Y-axis steering gear adopt digital rudders with high precision, small size, and large torque. machine in figure 1 The middle Y-axis steering gear 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com