Solar cell front face grid line and solar cell sheet printed with same

A technology of solar cells and front grid lines, which is applied to circuits, photovoltaic power generation, electrical components, etc., can solve the problems of reducing the utilization efficiency of solar cells, high production costs of solar cells, and increased use of conductive pastes. Effects of weight reduction, area reduction, and improved ability to collect electrons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

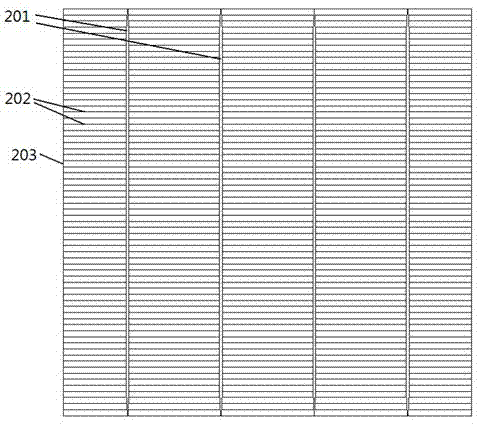

[0024] like figure 2 As shown, the front electrode of the solar cell includes four main grids 201, the width of the main grid is 1.2 μm, the distance between the main grid and the side is 24 mm, and the distance between the main grid is 35 mm. mm; it also includes 81 auxiliary grid lines 202 parallel to each other and perpendicular to the main grid, and the width of the auxiliary grid lines is 45 μm; it also includes two auxiliary grid lines 203 parallel to the main grid and connected to the endpoints of other auxiliary grid lines. 45μm, these two grid lines can increase the electrode circuit, prevent the circuit failure caused by the short grid of the auxiliary grid line, and increase the ability of the electrode to collect current.

[0025] The inventors of the invention have found that, using the electrode structure described in the present invention, the designed refractive index can be reduced from about 6% of the existing battery to 5.09%, which effectively increases th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com