Energy-saving condensing box

A condensing box, energy-saving technology, applied in the direction of steam condensation, chemical instruments and methods, separation methods, etc., can solve problems such as waste of cooling capacity, and achieve the effects of reducing manufacturing and operating costs, reducing energy consumption, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

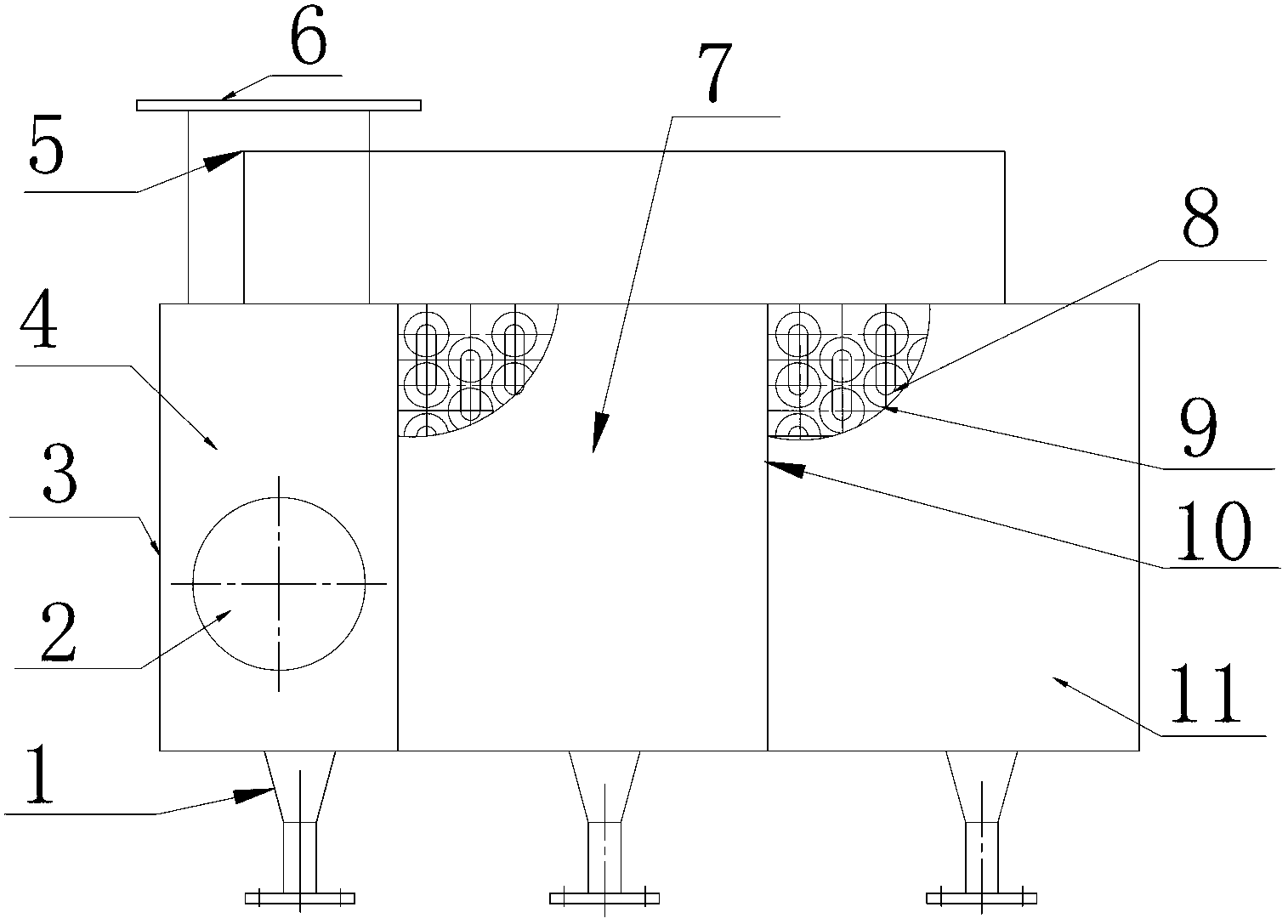

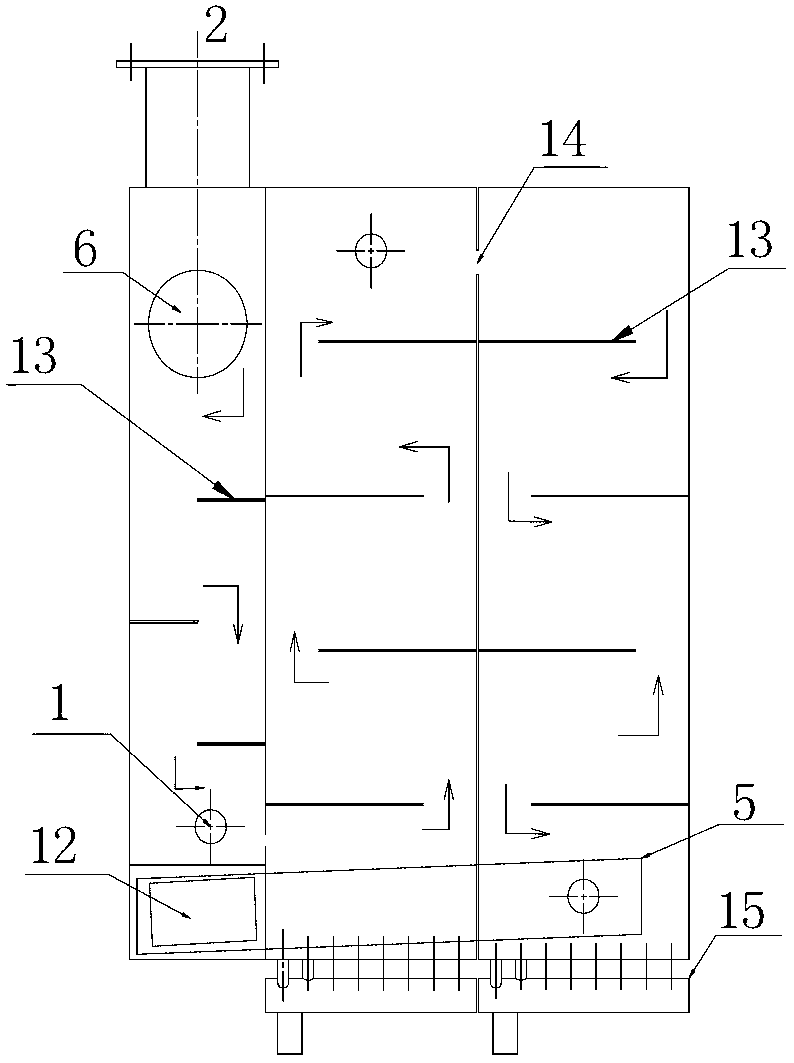

[0016] In order to solve the above-mentioned technical problems, the present invention provides an energy-saving condensing box, which includes a box body 3, and a partition 10 is arranged in the box body 3, and the box body is divided into a pre-cooling box 4, a middle box by the partition plate 10 Put the pre-cooling box 7 and the last condensing box 11; The plate 10 is respectively provided with diversion openings 14, so that the front pre-cooling box 4, the middle pre-cooling box 7 and the last condensation box 11 communicate with each other; the front pre-cooling box 4 and the last condensation box An exhaust gas return pipe 5 is arranged between the tanks 11, and the two ends of the exhaust gas return pipe 5 communicate with the front pre-cooling box 4 and the last condenser box 11 respectively. A plurality of baffles 13 are arranged inside the pre-cooling box 4, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com