Resin filling system in simulated moving bed separation technology

A technology of simulating moving bed and separation technology, applied in the field of resin filling system, can solve the problem of reducing the use of non-ionized water, and achieve the effect of shortening the filling time, large flow, and saving non-ionized water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

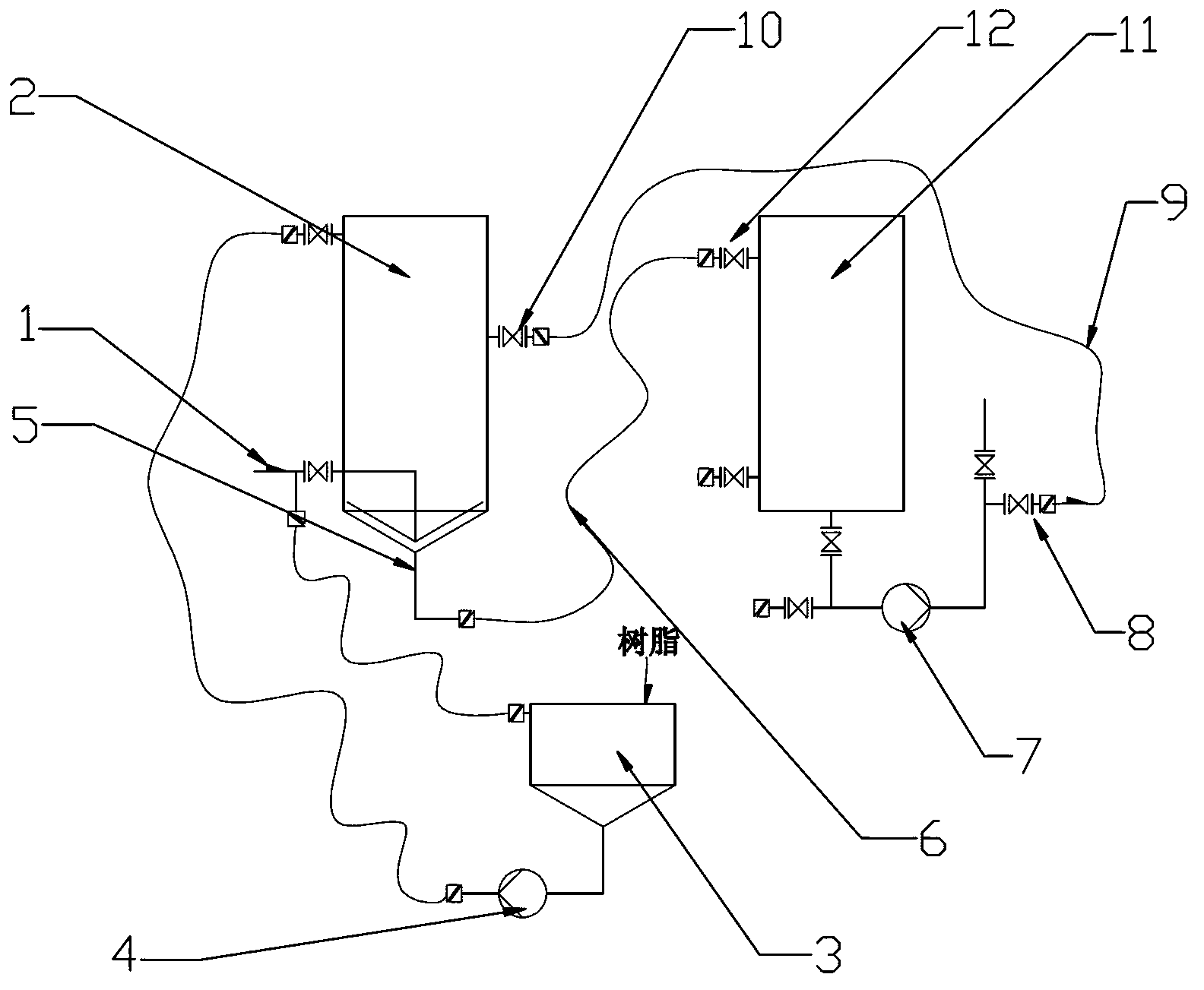

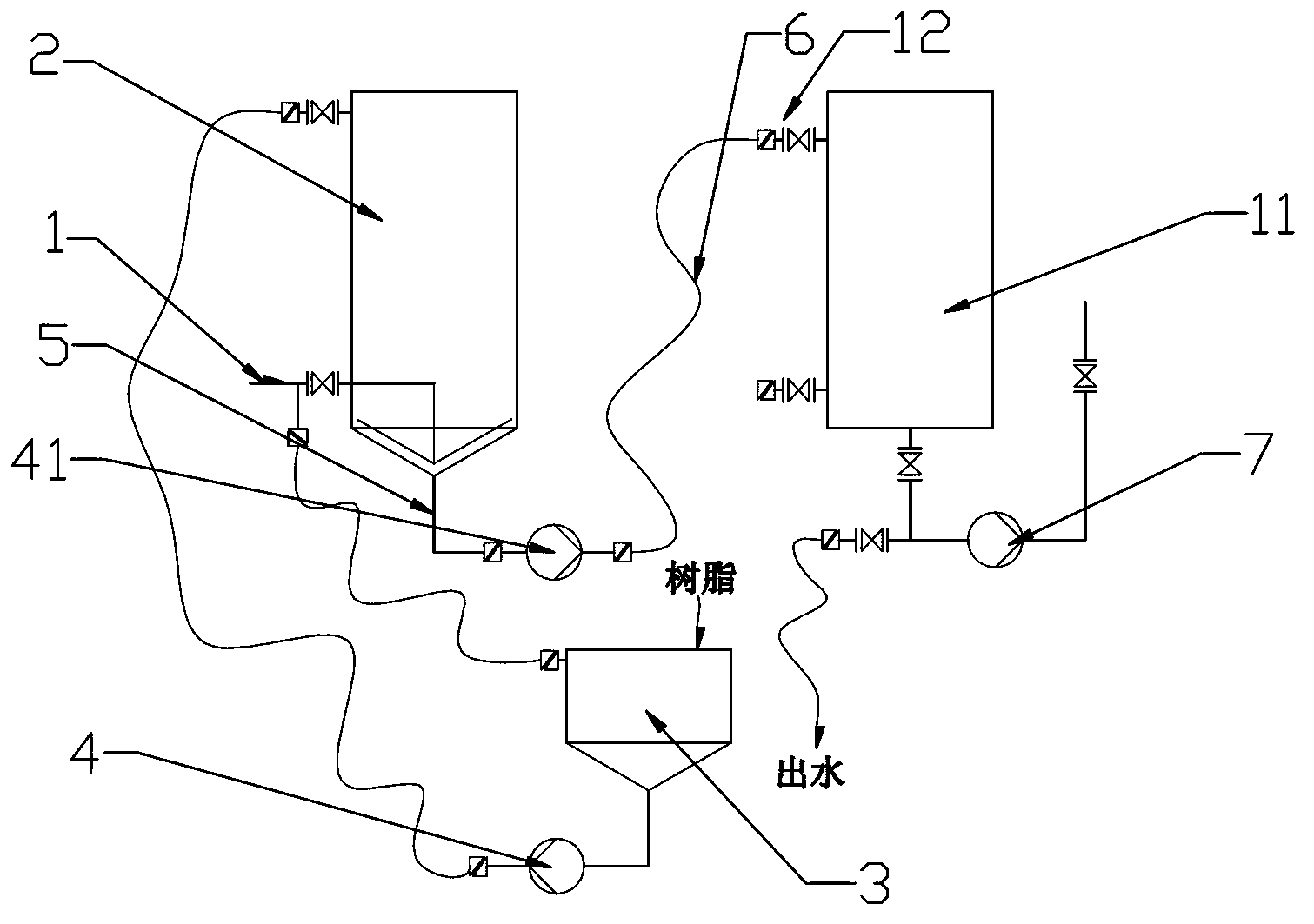

[0012] Such as figure 1 , to simulate the resin filling system in moving bed separation technology, including backwash tank 2, ion exchange column 11 and centrifugal pump 7 and other parts.

[0013] The resin tank 3 is injected with deionized water through the water inlet 1, and under the action of the first diaphragm pump 4, the resin is transported into the backwash tank 2, and the outlet 5 of the backwash tank is directly connected to the ion exchange column 11 through the pipeline 6 On the resin filling port 12. That is to say, when the separation medium of the simulated moving bed system migrates between devices, the diaphragm pump is no longer used as the power, but the existing centrifugal pump 7 in the system is used as the power, which reduces the blockage of the diaphragm pump and the frequent use of the diaphragm pump. question.

[0014] The specific process is: the outlet 5 of the backwash tank is no longer installed with a diaphragm pump, and is directly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com