Metal section mould with controllable cross section and gravity slantingly-rotated foundry technique of aluminum alloy cylinder cover of metal section mould

A metal type and controllable technology, applied in metal processing equipment, manufacturing tools, casting molding equipment, etc., can solve problems such as shrinkage cavity, affecting gas discharge, shrinkage porosity, etc., achieve stable mold filling and increase yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

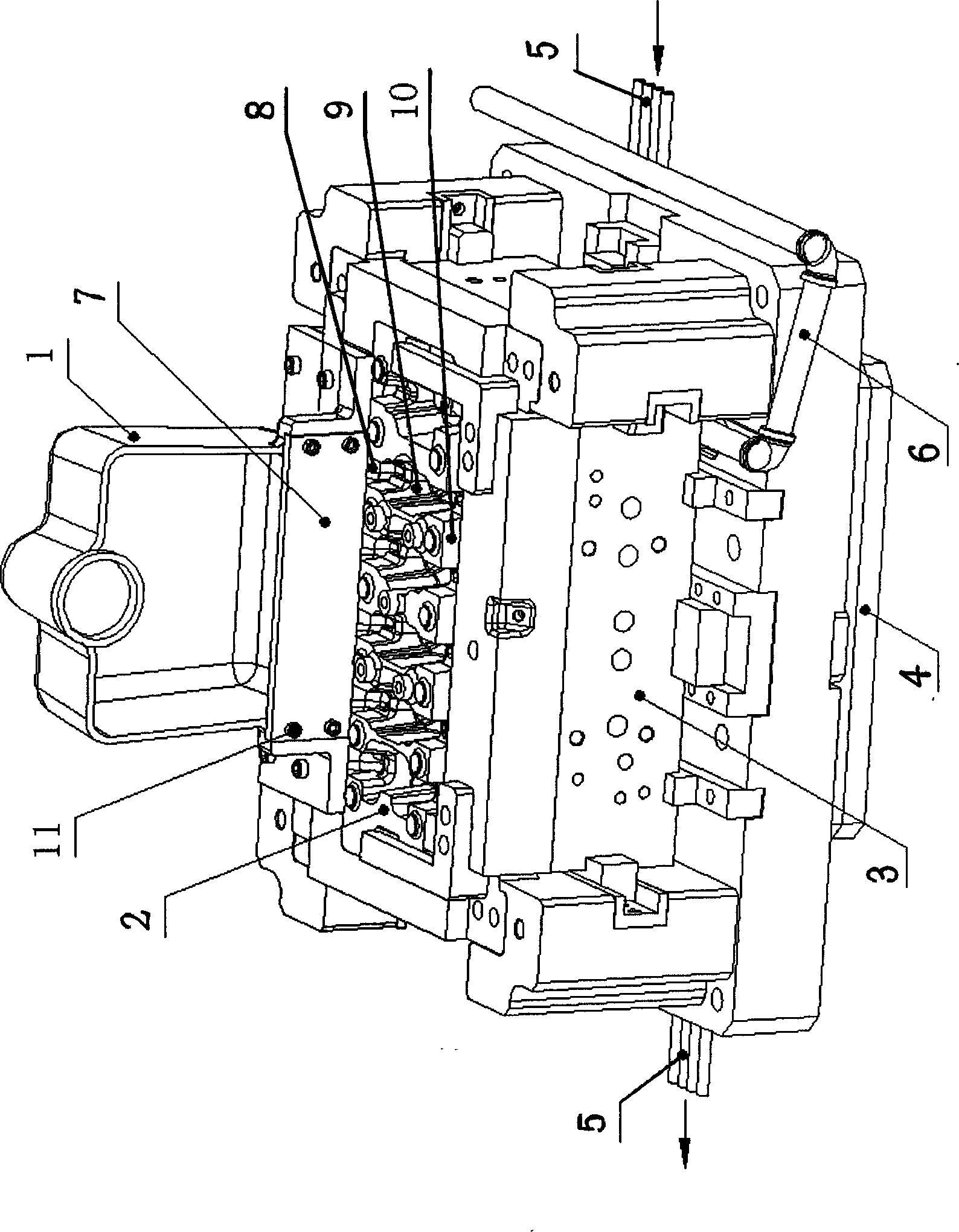

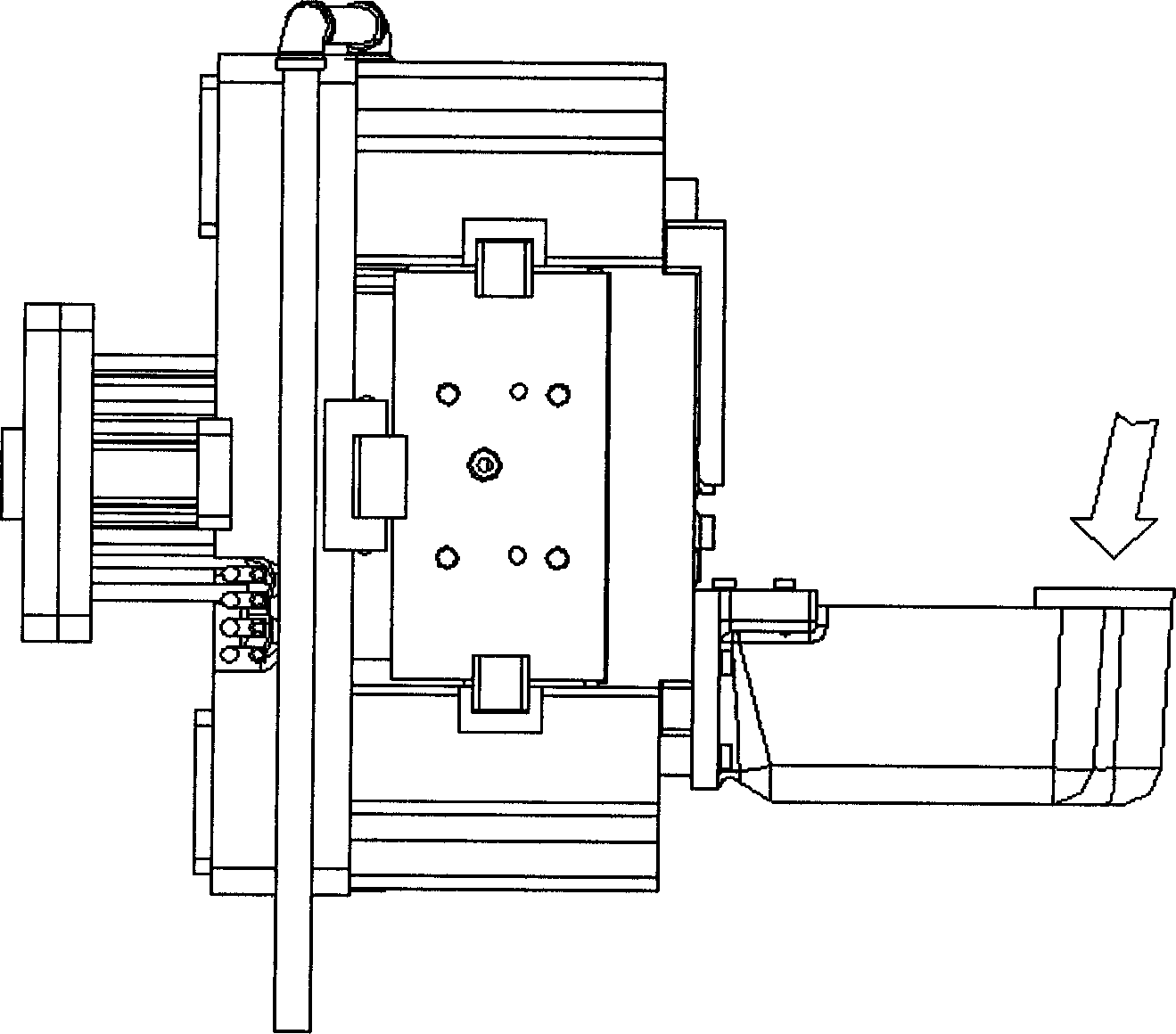

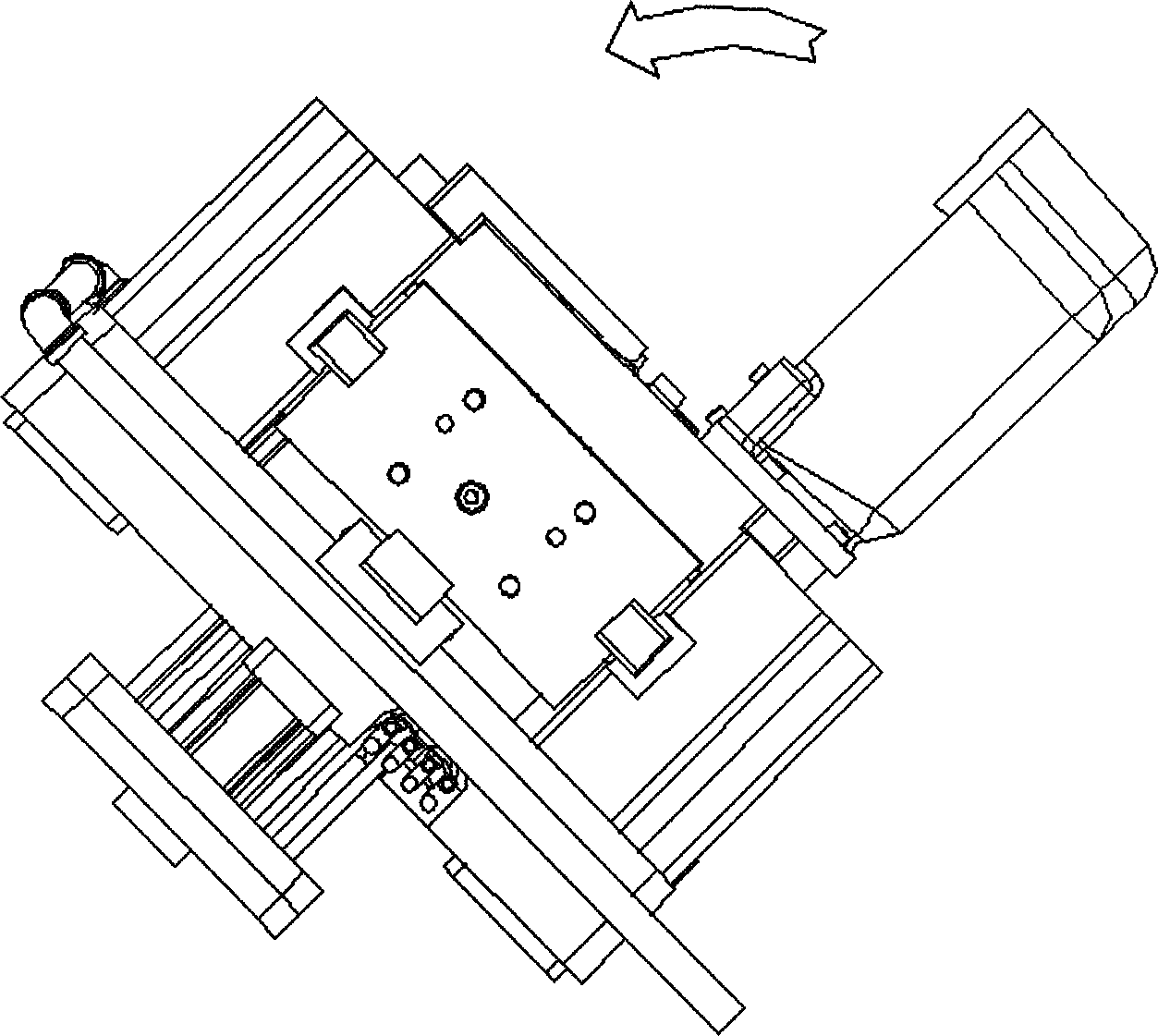

[0012] refer to figure 1 As shown, the present invention is applied to the cross-section controllable metal mold of the metal mold gravity tilting casting aluminum cylinder head process, including the sprue cup 1, the riser sand core 2, the molding module 3, the ejector device 4, and the water cooling device 5 , Negative pressure air extraction device 6, on the bottom of described sprue cup 1, and at the intersection of sprue cup 1 and riser sand core 2 (by screw 11) control section baffle plate 7 is housed. The sprue cup can also be called a controlled section sprue cup. The gravity tilting (control section) casting process of the aluminum alloy cylinder head obtained according to the cross-section controllable metal mold is: the first step is core making: the aluminum alloy cylinder head is water-jacketed with sand core, intake and exhaust passages The sand core, the oil chamber sand core and the riser sand core are manufactured and assembled respectively; the second step i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com