Ultra-large-diameter material switch angle valve

A technology with super-large diameter and switching angle, which is applied in the direction of lift valve, valve device, engine components, etc., can solve the problems that cannot meet the working requirements of super-large-diameter angle valve, affect the valve core assembly, and the valve core assembly is bulky, etc. It is not easy to achieve Jamming and deformation phenomenon, not easy to loosen, flexible movement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific examples.

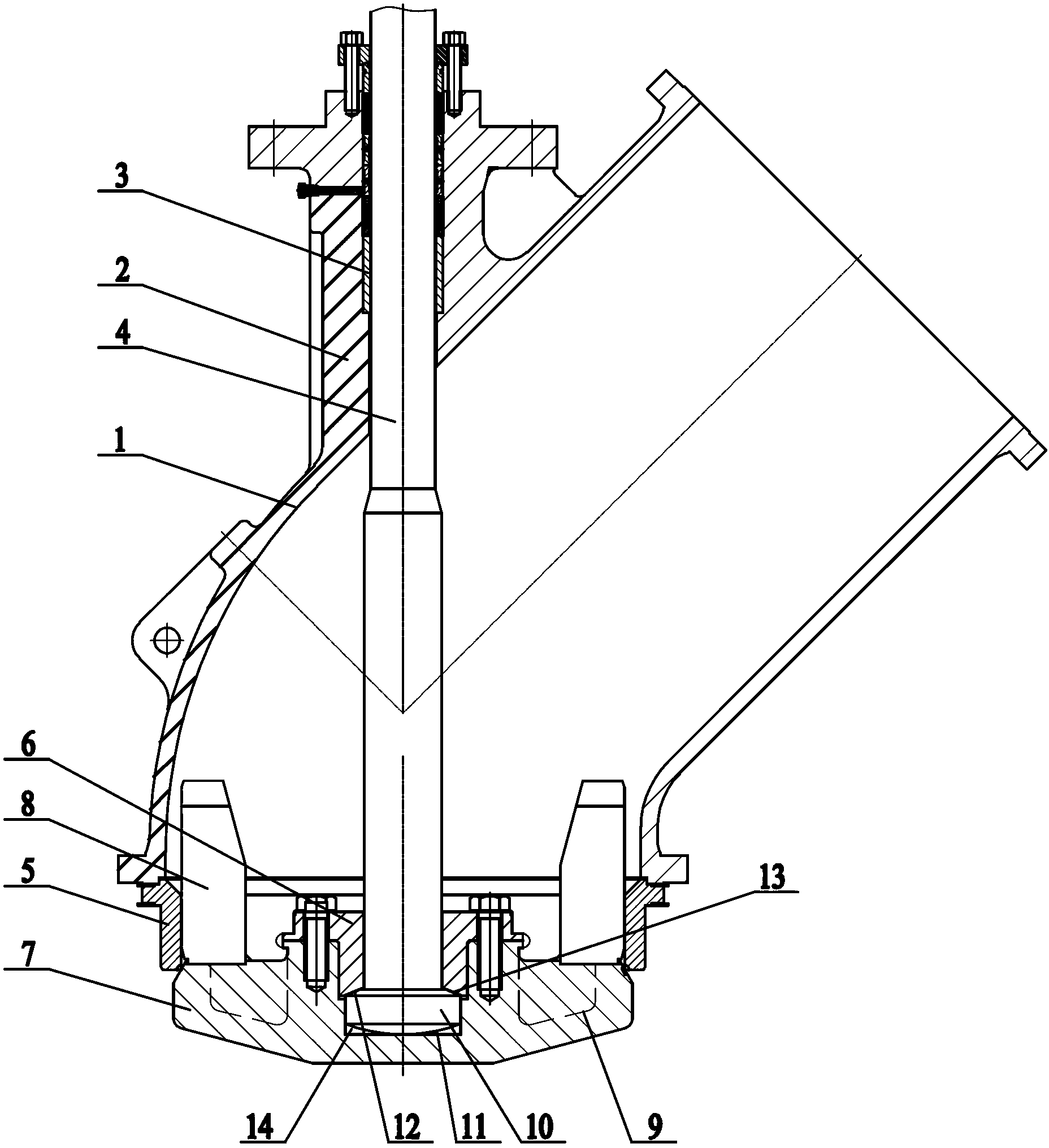

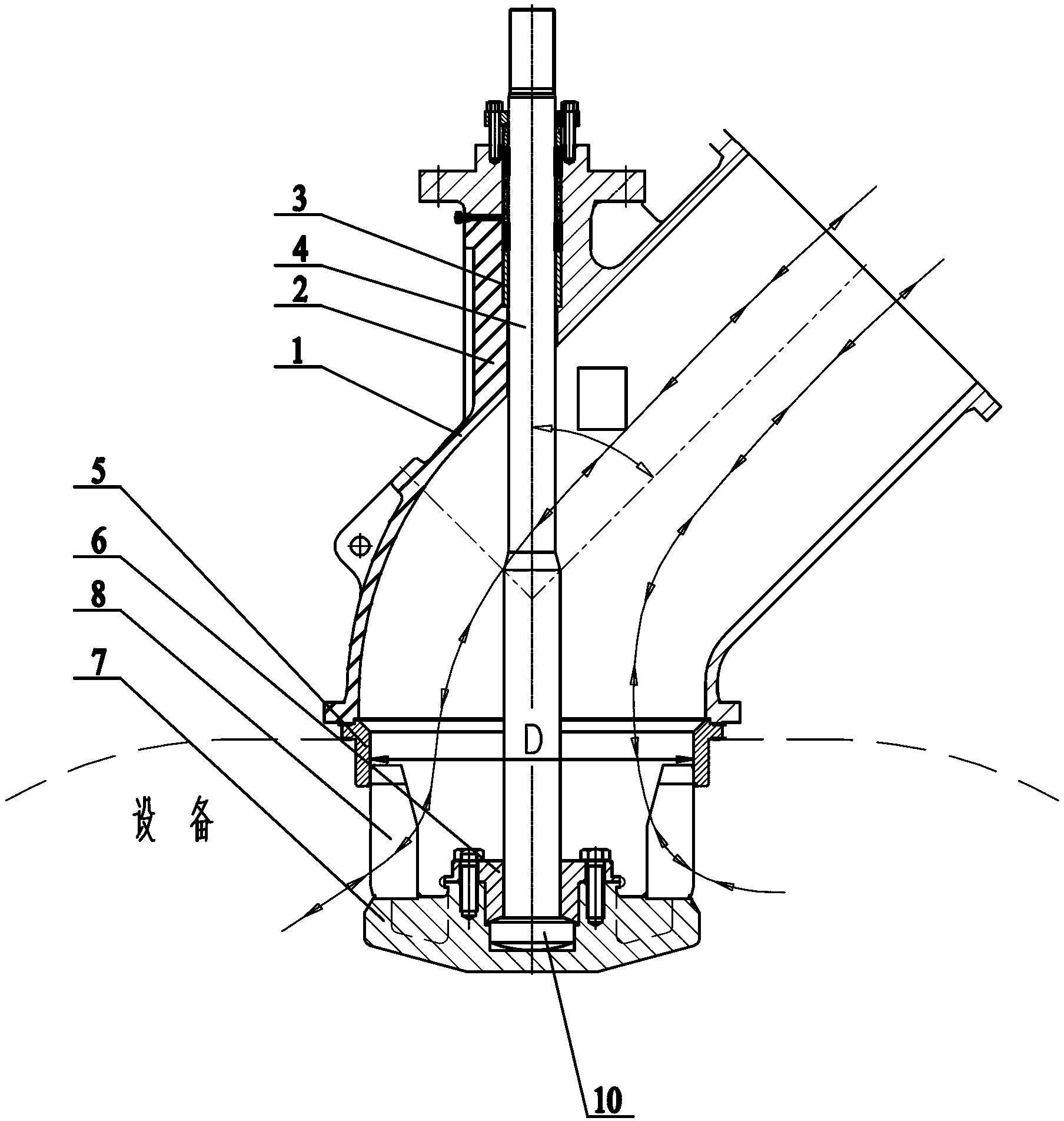

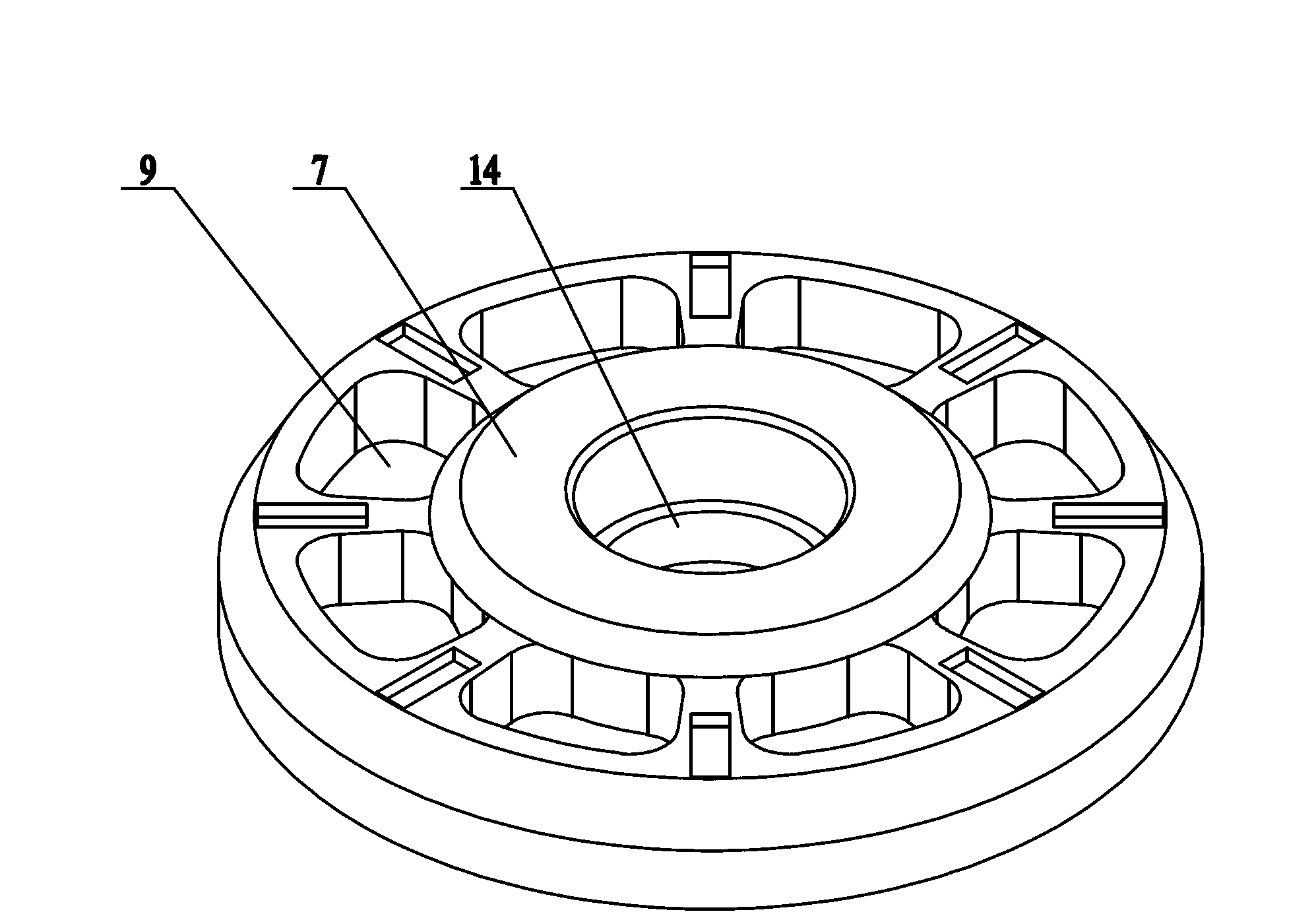

[0030] As shown in the figure, the super large diameter material switch angle valve has a stuffing box 2 processed on the valve body 1, a guide bush 3 is installed in the stuffing box 2, and a stuffing sliding sealing valve stem 4 is installed, and the valve stem 4 is connected to the The guide bush 3 is slidingly connected, and a thrust nut 6 is installed at the bottom end of the valve stem 4, and is connected with the valve disc 7 by fastening screws, and the valve stem 4, the thrust nut 6, and the valve disc 7 form a valve core assembly , The thrust nut 6 and the outer surface of the valve disc 7 are fastened by lip welding, and the end of the fastening screw is fastened by a figure-eight connection of corrosion-resistant stainless steel wire. The valve seat 5 is pressed against the valve body 1 by the valve core assembly. The tapered surface cooperates and seals between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com