Multi-cereal staple food flour and production method thereof

A production method and grain technology, applied in the field of multi-grain staple food powder and its production, can solve the problems of protein titer, dietary fiber content, no reduction in glycemic index, low nutritional value of wheat flour, etc., and achieve good nourishing effect, Delay the aging of starch and improve the effect of immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

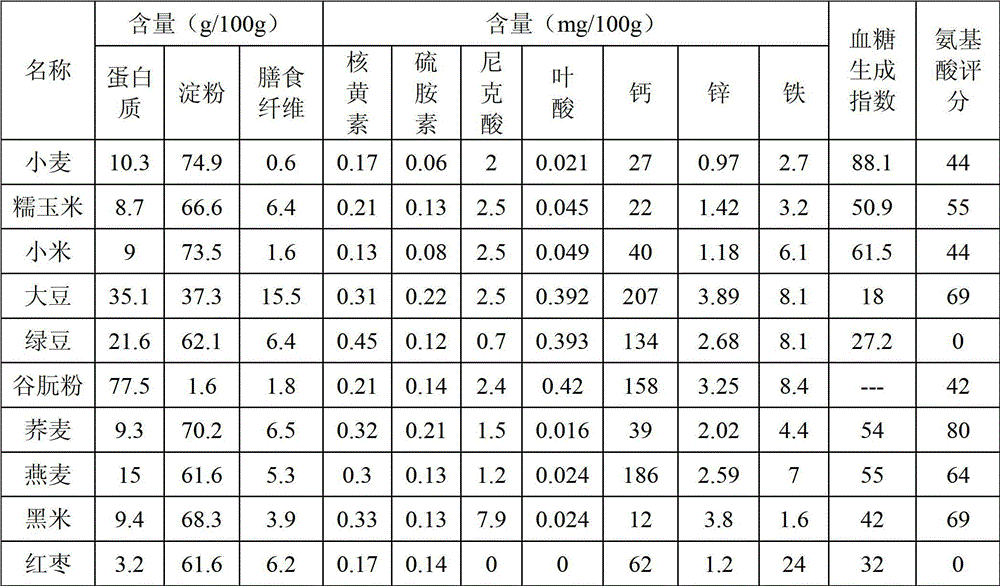

Problems solved by technology

Method used

Image

Examples

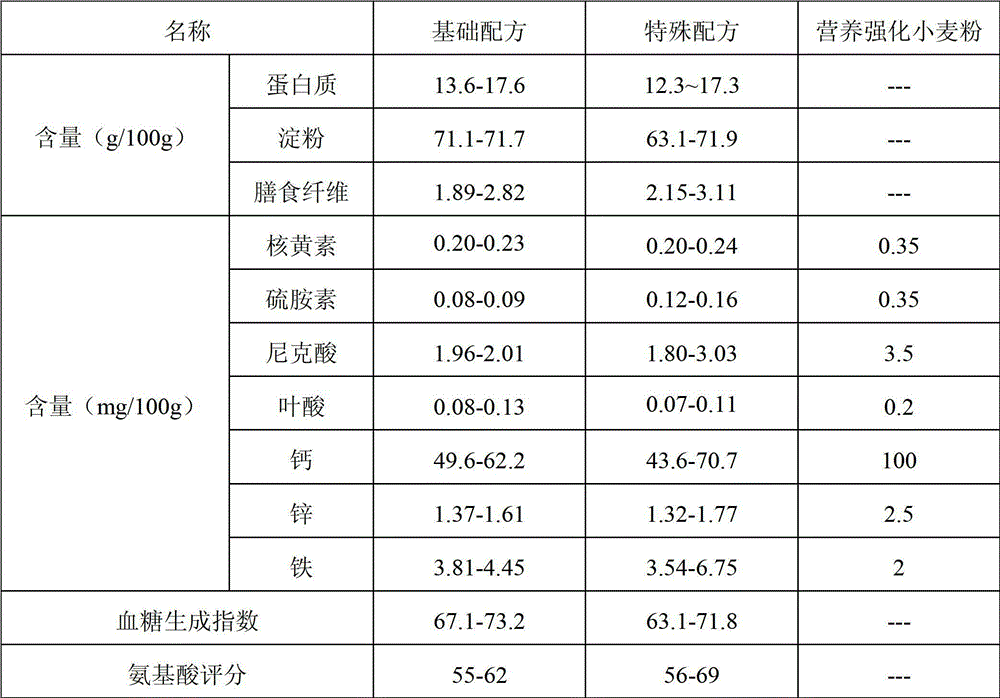

Embodiment 1

[0051] The production method of multi-cereal staple food powder of the present invention comprises the following steps:

[0052] a. Washing the dry grains of waxy corn and then peeling them to make powder, separating skin powder and heart powder;

[0053] b. extruding and puffing the heart powder gained in the step b;

[0054] c. pulverizing the heart powder extruded and puffed in step c to 80-100 mesh;

[0055] d. Take soybeans and mung beans, wash them, peel them to make powder, and grind them to 80-100 mesh;

[0056] e. Wash the millet and grind it to 80-100 mesh;

[0057] f. Weigh 7kg of waxy corn puffed heart powder, 10kg of soybean flour, 15kg of mung bean flour, and 7kg of millet flour prepared by the above method, then add 6kg of gluten powder and 60kg of wheat flour (produced by traditional flour making methods), mix evenly, and obtain this product Invention of basic formula products.

Embodiment 2

[0059] According to the production method of Example 1, weigh 10kg of waxy corn puffed heart powder, 20kg of soybean flour, 20kg of mung bean flour, and 10kg of millet flour, then add 10kg of gluten powder and 80kg of wheat flour (produced by traditional flour-making methods), mix evenly, Promptly obtain the basic formula product of the present invention.

Embodiment 3

[0061] According to the production method of Example 1, weigh 5kg of waxy corn puffed heart powder, 5kg of soybean flour, 20kg of mung bean flour, and 5kg of millet flour, then add 1kg of gluten powder and 50kg of wheat flour (produced by traditional flour milling methods), mix evenly, Promptly obtain the basic formula product of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com