Intelligent garbage collection container

A garbage and intelligent technology, applied in the field of trash cans, can solve the problems of unsanitary garbage bags, increase manufacturing costs, and high manufacturing costs, and achieve the effects of saving occupied space, improving use efficiency and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

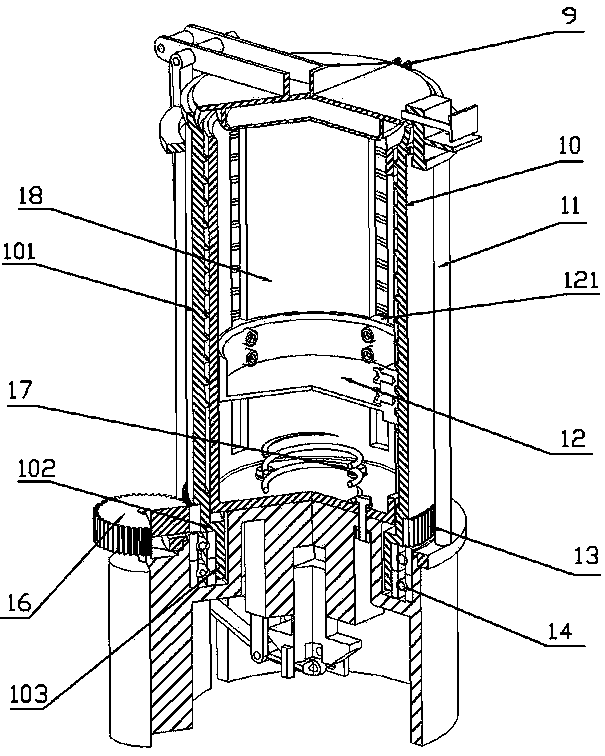

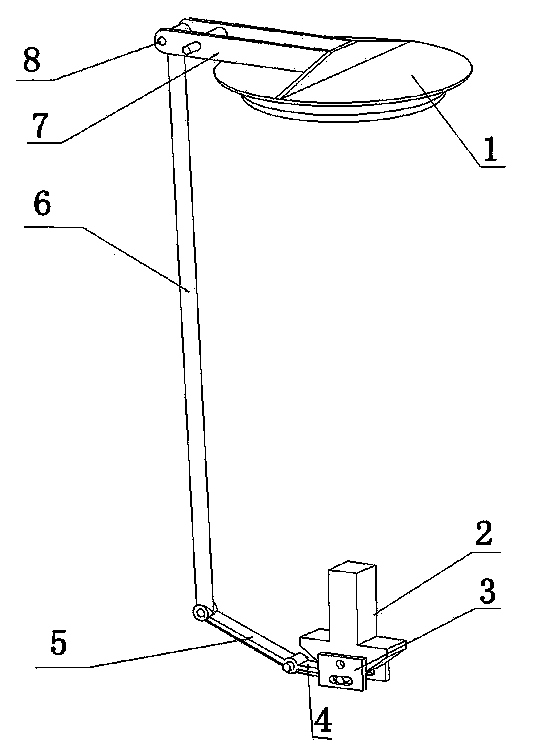

[0019] Embodiment 1 of the intelligent garbage storage bin of the present invention, as Figure 1-2 As shown, it includes a bucket frame 11 and a bucket cover 1 located on the top of the bucket frame 11. The bucket frame is equipped with an outer cylinder 10 rotating under the bucket cover and is provided with a motor that drives the rotation of the outer cylinder. It has an edge for driving the mouth of the garbage bag to rotate with the outer cylinder. The outer cylinder 10 includes a first annular cylinder 101 from top to bottom, and an inwardly extending cylinder integrally fixed at the lower part of the first annular cylinder. The platform 102 that enters, the second annular cylinder 103 that is integrally arranged on the lower part of the inner end of the platform, the inner wall of the first annular cylinder is provided with an internal thread, the outer peripheral surface of the second annular cylinder and the inner wall of the bucket frame Rolling bearings 14 are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com