Lateral gas guide anode structure for aluminum electrolysis

A technology of anode structure and aluminum electrolysis, which is applied to the field of gas-conducting structure on the side of the anode, can solve the problems of affecting the normal discharge of gas and blocking the perforation of the anode, and achieve the effects of saving energy, reducing consumption, reducing heat dissipation, and reducing the thickness of the bubble layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

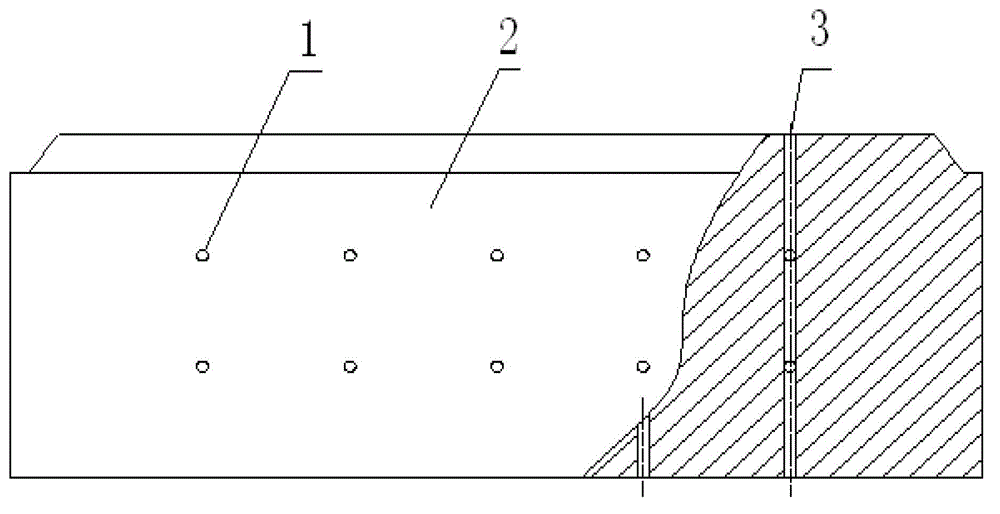

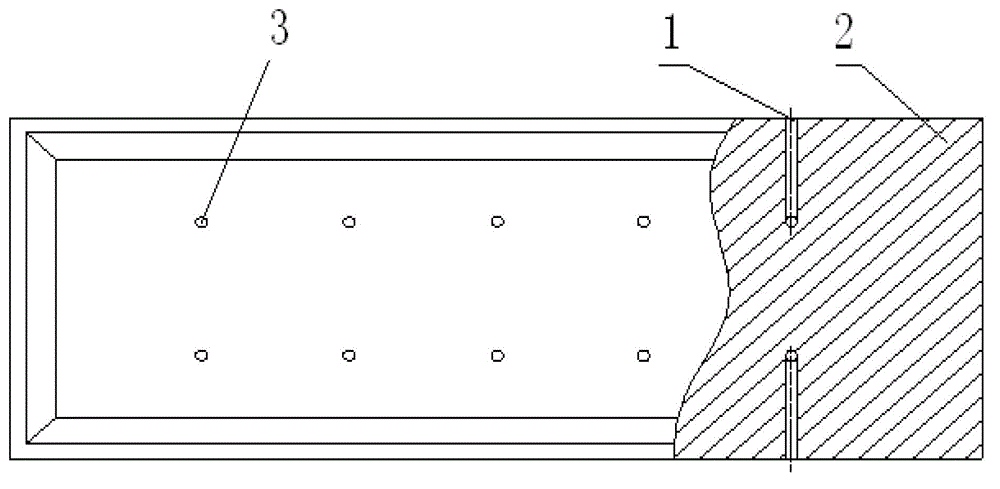

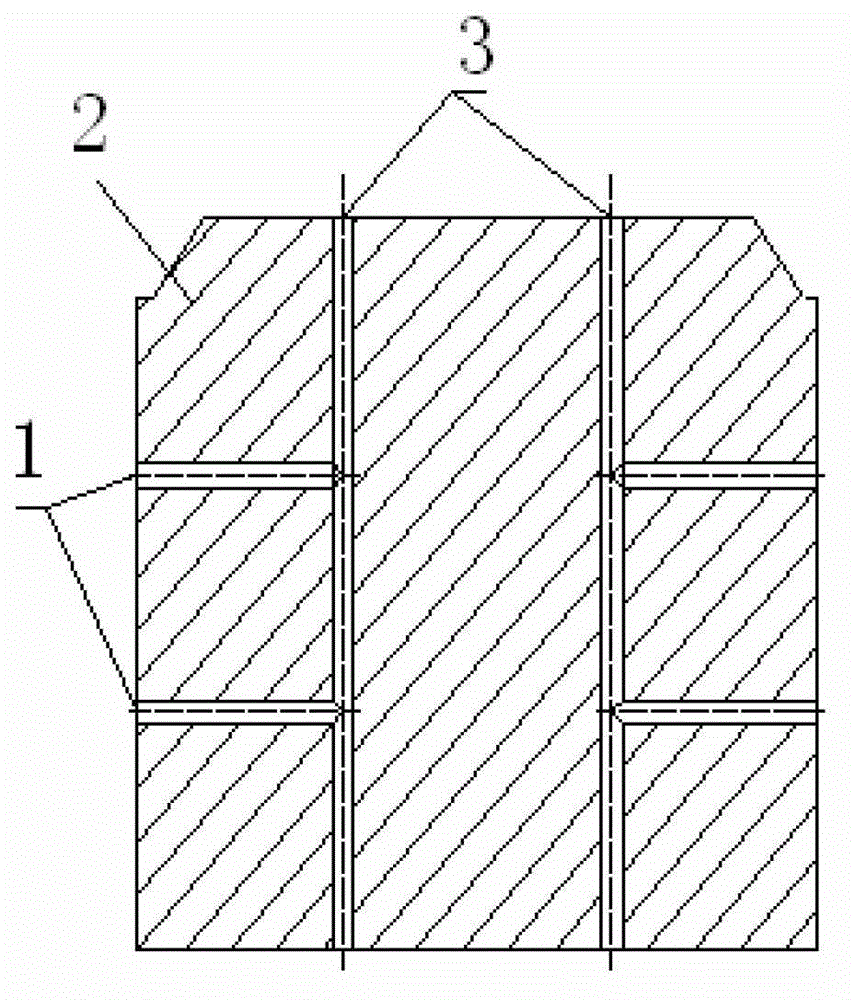

[0034] In the processing stage of the anode carbon block 2, two rows of longitudinal air guide holes 3 through the anode are drilled equidistantly along the length direction of the anode carbon block 2, 4 to 7 in each row, and the hole diameter is 10 mm to 30 mm, and then on the side of the anode carbon block 2 Drill 2 to 3 rows of parallel or staggered side exhaust holes 1 at the corresponding positions of the longitudinal air guide holes 3. The aperture is equal to the aperture of the longitudinal air guide hole 3, while ensuring that the side exhaust hole 1 communicates with the longitudinal air guide hole 3, and the top of the longitudinal air guide hole 3 is sealed, see figure 1 , figure 2 with image 3 , The anode carbon block 2 is provided with 5 longitudinal air holes 3 and 2 rows of horizontal side air vents 1 . Before changing poles, it is necessary to ensure that all exhaust holes are unobstructed to prevent local blockage from affecting the overall exhaust effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com