Method for welding and connecting circular seam on over-sized spanning variable cross-section continuous steel box beam bridge

A connection method and variable cross-section technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as less research, achieve advanced technology, facilitate promotion, and improve safety indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0038] The present invention relates to a bolt welding connection method for the upper circular seam of a super-large-span variable-section continuous steel box girder bridge, which comprises the following steps:

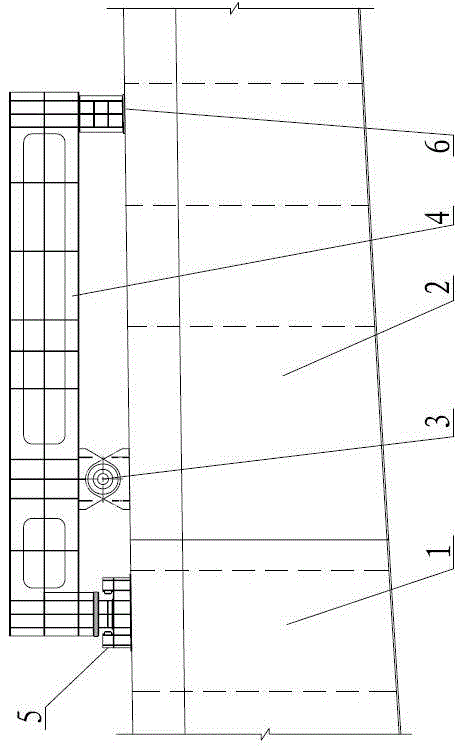

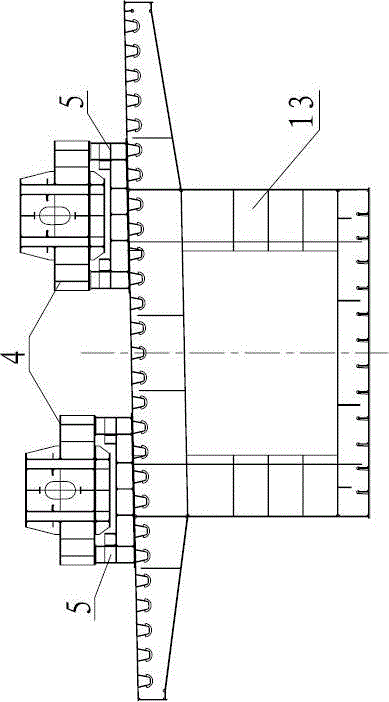

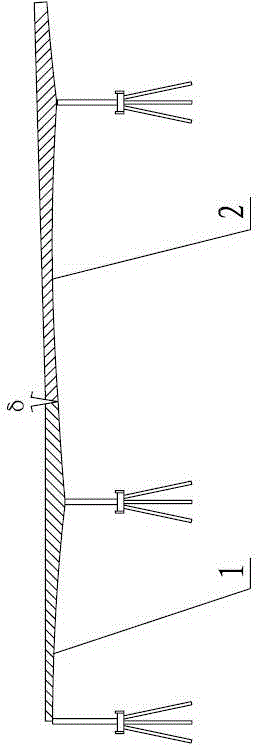

[0039] S1. The hoisting of the large section completes the preliminary connection of the temporary corbel 4 corresponding to the ring seam of the steel box 13 on the bridge deck. Located on the rear fulcrum 6 on the bridge surface of the large section 2 to be installed, the rough matching of the interface ring seam between the large section 2 to be installed and the installed large section 1 is completed; figure 1 , figure 2 shown;

[0040] S2. During the time when the temperature is relatively stable at night, that is, from 22:00 to 4:00, measure the temperature of the steel box girder roof and floor, and use the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com