Preparation method and application of resin composition used for preparing fireproof heat insulation fiber coating

A technology of resin composition and thermal insulation coating, which is applied in the direction of fireproof coating, coating, fiber treatment, etc. It can solve the problems of not being comfortable enough to wear, restricting the development of thermal insulation clothing market, and not being able to have bright colors, so as to improve safety Performance index, strong anti-corrosion, bright and clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

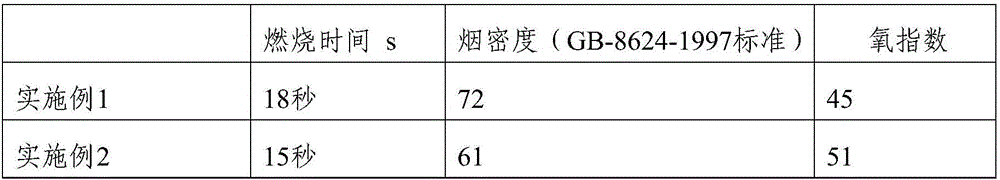

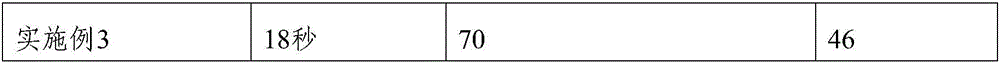

Examples

Embodiment 1

[0028] The raw material ratio is as follows:

[0029] project

raw material name

parts by mass

raw material

Formaldehyde (37%)

300

raw material

Melamine (99.9%)

150

pH regulator

10

additive

Carbonamide

9

paraffin

3

detergent

0.3

thickener

Phosphoric acid (64%)

23.6

[0030] Add formaldehyde and sodium hydroxide to the reaction kettle, and the resulting mixture has a pH value of 10; raise the temperature to 45°C, add melamine, carbonamide, paraffin, and borax, stir, and then raise the temperature to 65°C for 1 hour. Then divide the phosphoric acid into three equal batches and add it to the reaction kettle, and heat up to 95°C. At this time, the viscous system in the reaction kettle gradually becomes thinner, and the reaction is complete, and the solid content of the product is 30%. Phosphoric acid is weighed by volume, 2...

Embodiment 2

[0033] The raw material ratio of resin composition is as follows:

[0034] project

raw material name

parts by mass

raw material

Formaldehyde (37%)

300

raw material

Melamine (99.9%)

150

pH regulator

10

additive

Carbonamide

9

paraffin

5

detergent

0.3

thickener

Phosphoric acid (64%)

23

[0035] The preparation method is the same as in Example 1.

[0036] The fabric was treated in the same manner as in Example 1.

[0037] Example 2:

[0038] The raw material ratio of resin composition is as follows:

[0039] project

raw material name

parts by mass

raw material

Formaldehyde (37%)

300

raw material

Melamine (99.9%)

150

pH regulator

10

additive

Carbonamide

9

paraffin

6

detergent

0.3

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com