Method for extraction separating hop extract and hop essential oils from hops

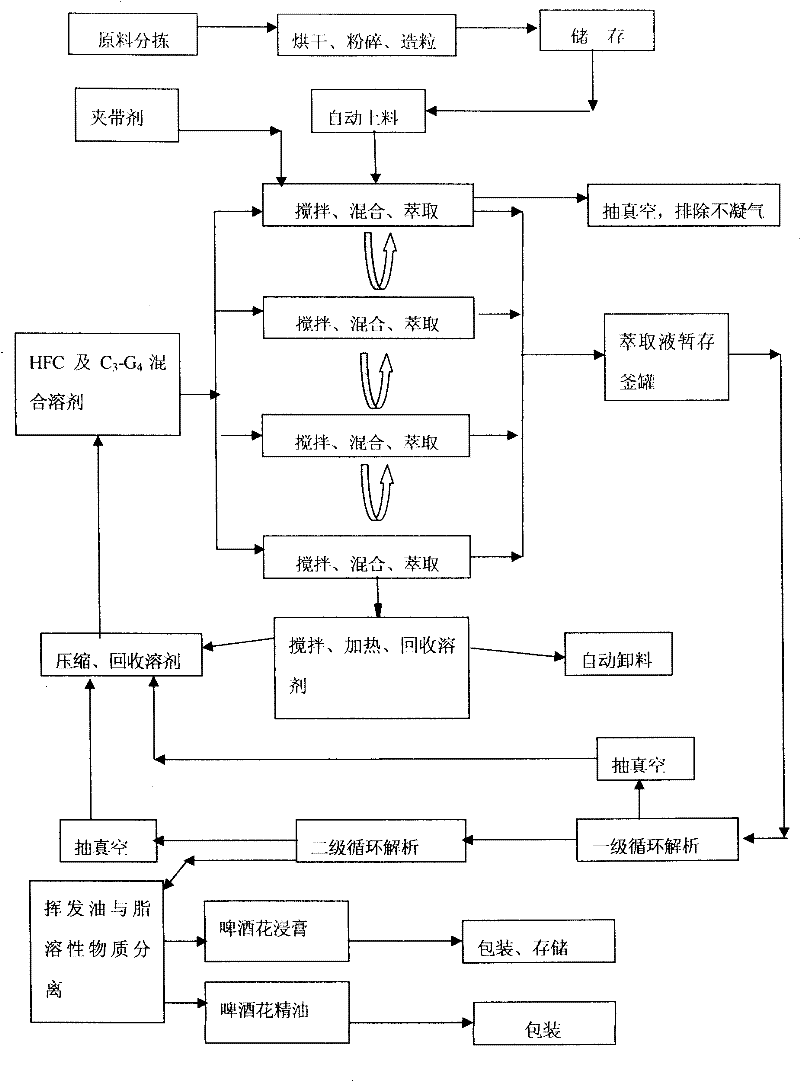

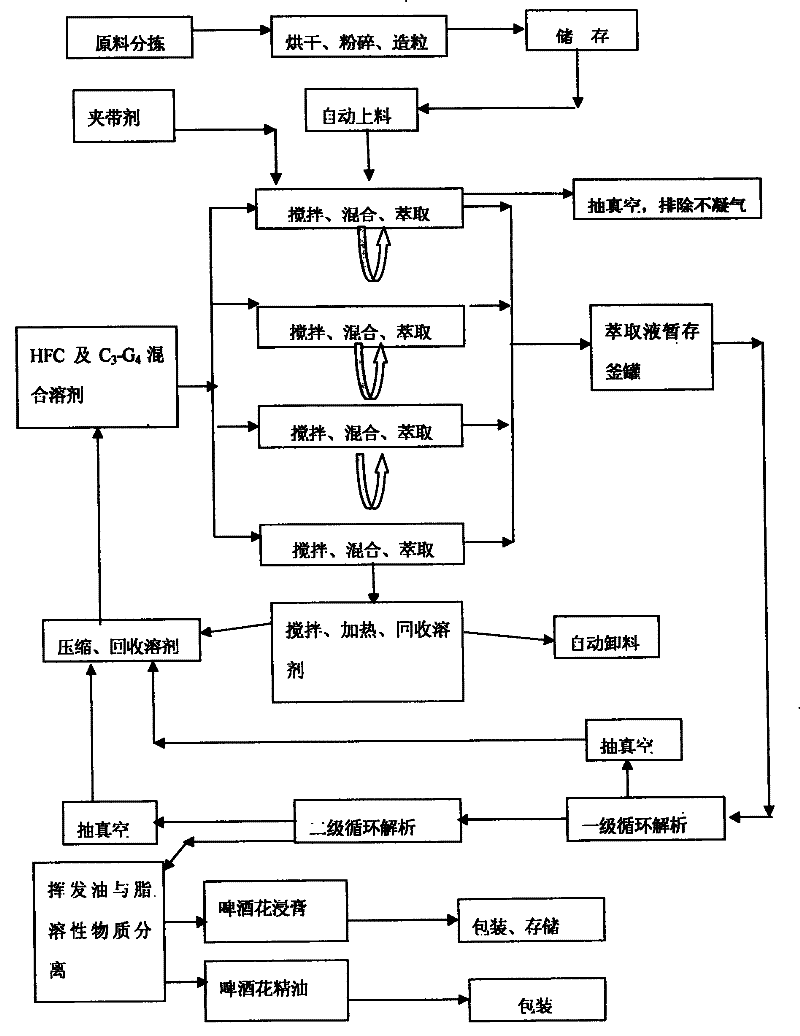

A technology of hops and extracts, which is applied in the treatment of hops, brewing of beer, biochemical equipment and methods, etc. It can solve the problems of inability to extract and separate hops extract and hop essential oil at the same time, expensive products, and constraints of large-scale application, etc. problems, to achieve the effect of improving market competitiveness, reducing process difficulty and project cost, and reducing energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

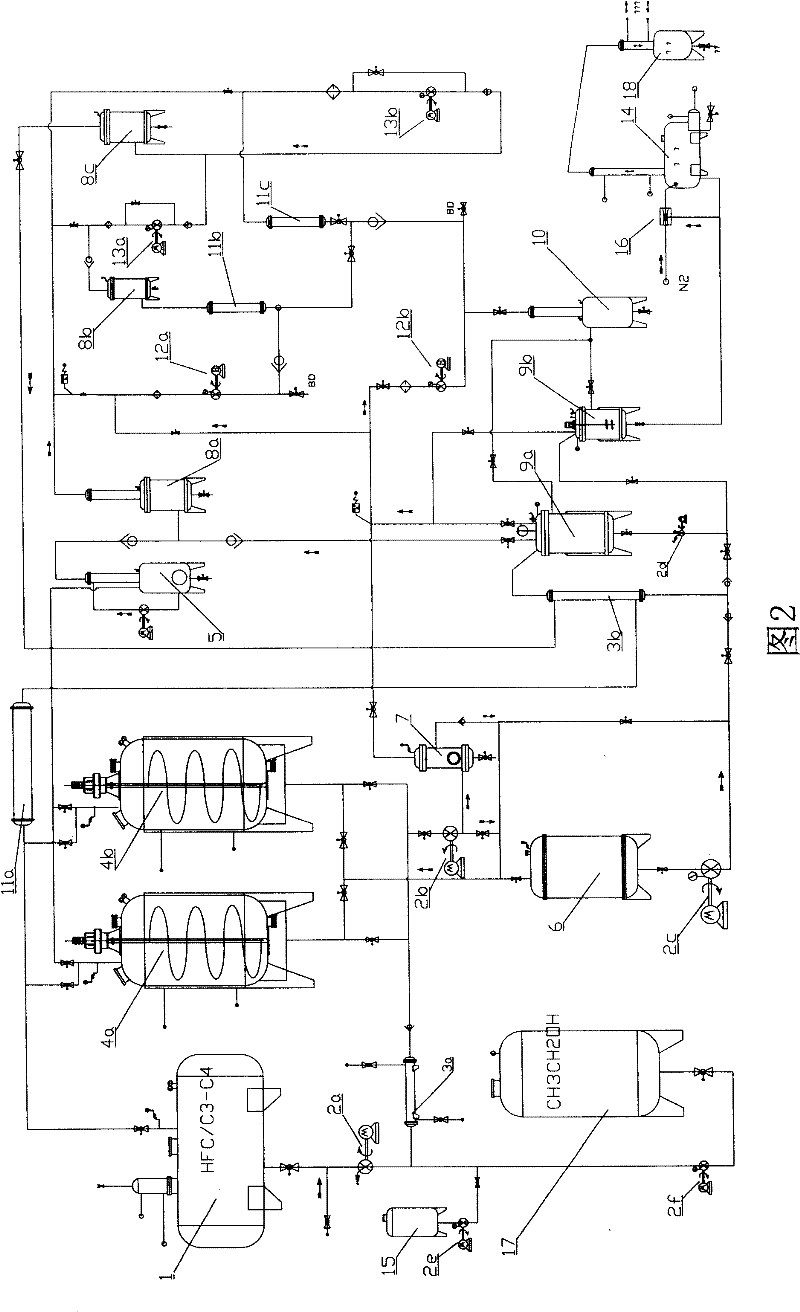

[0037] Embodiment 1: 406A fluid extraction separates hop extract and hop essential oil, comprises the following steps:

[0038](1) Dried and crushed the hop raw material, granulated according to the diameter of Φ3mm-Φ6mm, and put it into the extraction kettle. When the volume of the raw material reached 1 / 2 of the volume of the extraction kettle, stop feeding and close the feeding and discharging control butterfly valve.

[0039] (2) The vacuum pump reduces the vacuum of the extraction kettle to 1×10 4 Below pa, remove the non-condensable gas in the kettle.

[0040] (3) Pour the liquid 406A in the solvent storage tank into the extraction kettle until the hop raw material is completely submerged, heat the extraction kettle to raise the temperature to 40°C-45°C, and the extraction pressure to 0.8MPa-1.3MPa, stir and mix the raw materials and solvent, soak and extract For 50 minutes, filter and separate the solid-liquid phase; repeat the extraction three to four times, and injec...

Embodiment 2

[0044] Example 2: Separation of hop extract and hop essential oil by hydrofluorocarbon 134A fluid extraction

[0045] The steps included in this embodiment are all the same as those in Embodiment 1.

Embodiment 3

[0046] Example 3: Extraction and separation of hop extract and hop essential oil by 406A fluid and its ethanol mixed solution

[0047] Steps (1) and (2) of this embodiment are the same as those of Embodiment 1.

[0048] (3) The liquid 406A in the solvent storage tank is injected into the extraction kettle until the hop raw material is fully submerged, then the 95% ethanol solution in the entrainer tank is injected into the extraction kettle to change the polarity of the mixed solvent, and the volume ratio of 406A and ethanol is controlled to be about The ratio is 4:1. Stir the raw materials, solvent, and entrainer to make them fully mixed.

[0049] Steps (4) and (5) of this embodiment are the same as steps (3) and (4) of Embodiment 1.

[0050] (6) The mixed solution separated by the first-level analysis is injected into the second-level analysis kettle by the delivery pump, heated by the jacketed heat exchanger, and continuously extracted by the vacuum pump group. -2 Under t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com