Composite thermal insulation board with circulation channel dual-cavity structure

A composite thermal insulation and circulation channel technology, applied in thermal insulation, building components and other directions, can solve the problems of heat drying deformation, monotonous expression, different materials, etc., and achieve the effects of low cost, good decorative effect and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make it easy to understand the technical means, creation features, achieved goals and effects of the present invention, the present invention will be further described below with reference to the specific figures.

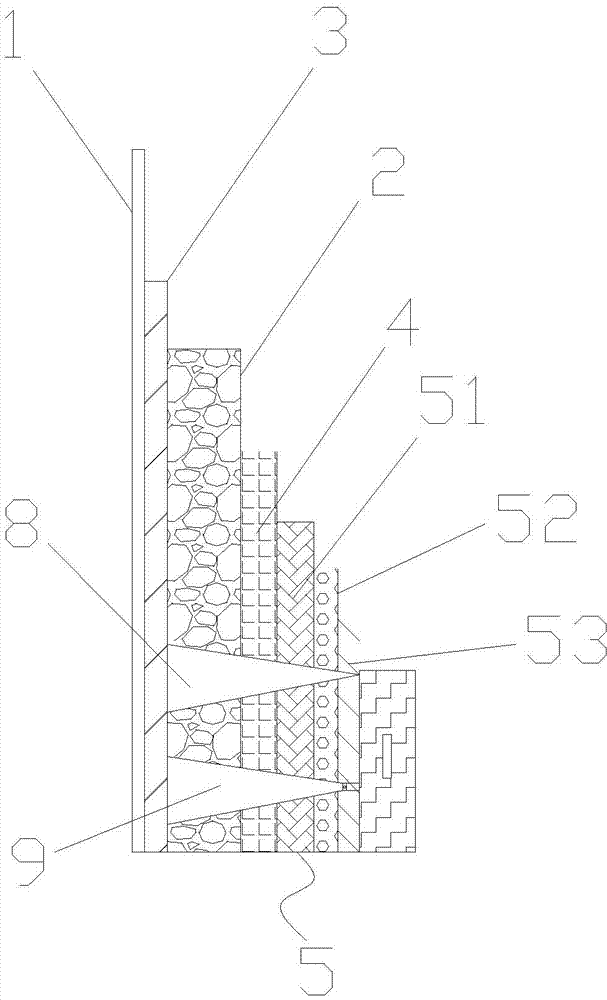

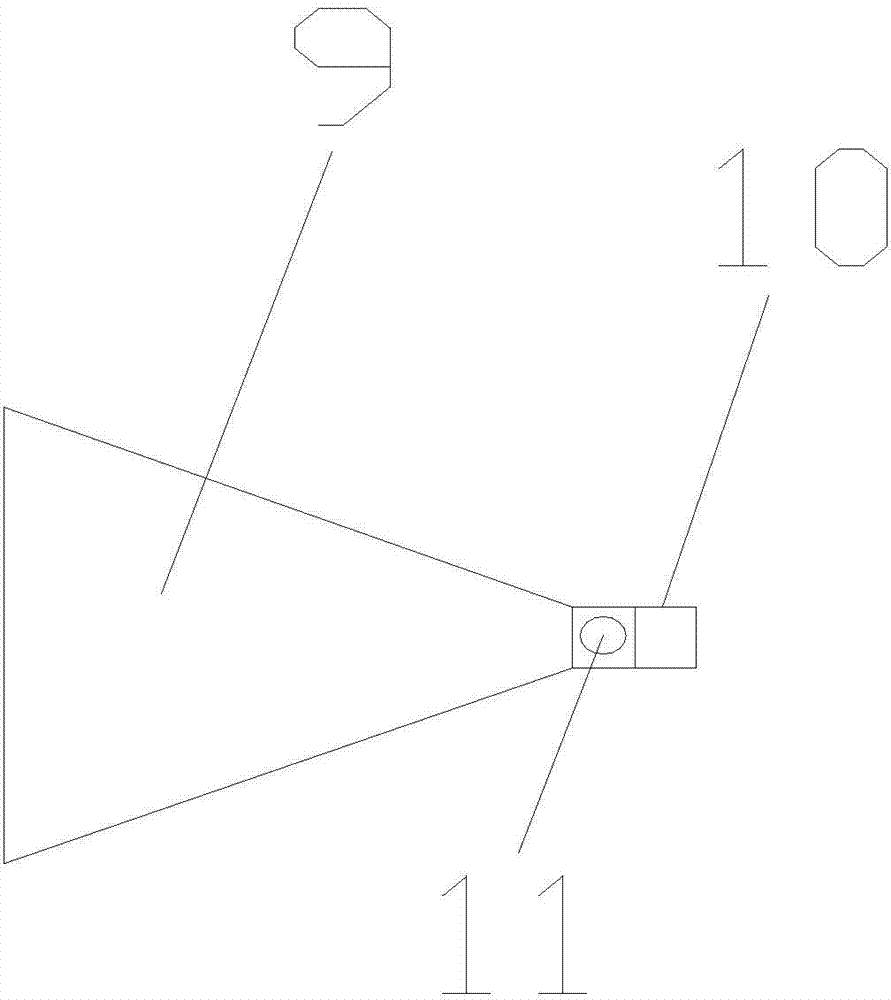

[0022] like figure 1 as well as figure 2 As shown in the figure, a composite thermal insulation board with a dual-cavity structure of circulation channels, its matrix is a composite thermal insulation material layer installed outside the cement surface layer, and the composite thermal insulation material layer consists of an outer soft stone layer 1, and a soft stone layer 1 The calcium silicate board layer 2 bonded by the bonding mortar 3, the anti-cold bridge pad (XPS) layer 4 bonded with the calcium silicate board layer 2, and the airbag structure layer 5 bonded with the cement surface layer are formed. The outer part of the layer 5 is a thermal insulation strip 51 that plays a supporting role. The thermal insulation strip 51 has a built-i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com