Method for reducing silt coal slime in underground water sump of large water coal mine

A technology for large-water coal mines and silted coal sludge, which is applied in the field of coal mining, can solve the problems of increasing the labor intensity of miners, shortening the working cycle of dredging water silos, and reducing coal production efficiency, so as to reduce the amount of silt and ensure the water storage capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

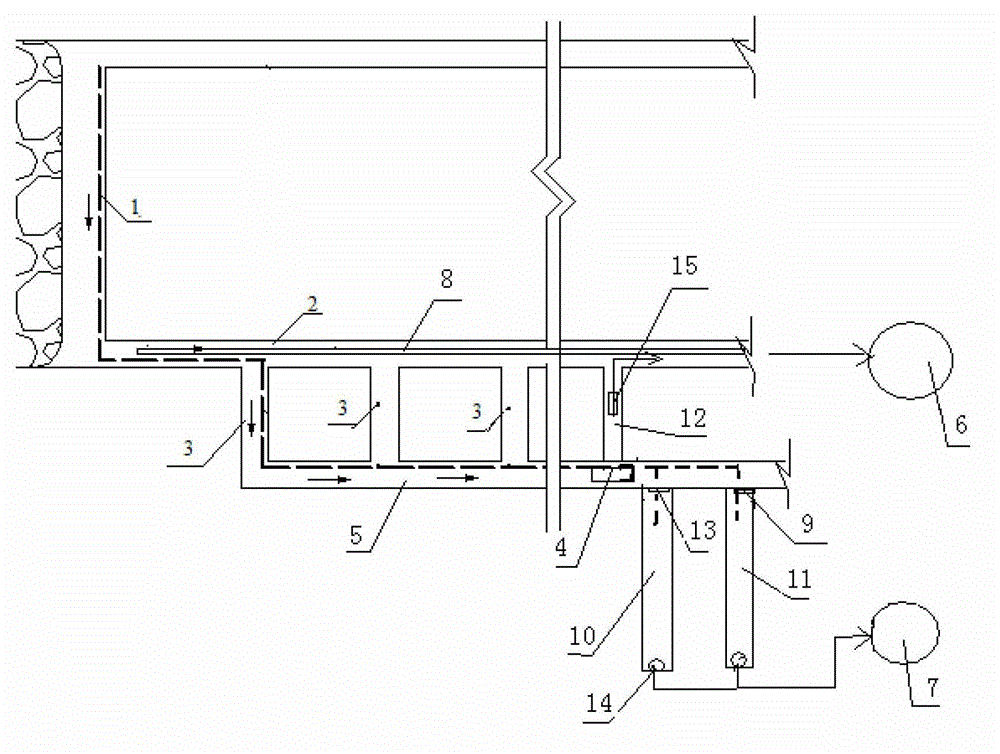

[0014] Such as figure 1 Shown, a kind of method for reducing silt in the bottom water tank of Dashui Coal Mine is as follows:

[0015] 1. Before the mining of working face 1, first develop a drainage roadway 5 along the conveyor belt lane 2. The elevation of the drainage laneway 5 should be lower than that of the conveyor belt lane 2, and the design has an artesian slope; in the conveyor belt lane 2 Through holes 3 are set up at regular intervals, through which the conveyor belt lane 2 and the drainage lane 5 are connected; at the end of the drainage lane 5, a vibrating screen 4 is installed, and after the vibrating screen 4, a roadway 2 and the conveyor belt lane are developed. Connected coal transport roadway 12; transport equipment 15 is arranged in the coal transport roadway 12; the first water storage sedimentation tank 10 and the second water storage sedimentation tank 11 are developed beside the discharge roadway 5, and the bottom surface elevation of the water storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com