Optical path assembly auxiliary device of three-axis integral optical fiber gyroscope

A fiber optic gyroscope and assembly-assisted technology, which is applied to measurement devices, Sagnac effect gyroscopes, instruments, etc., can solve the problems of increased difficulty, large volume and weight, complicated fiber routing paths and fiber coiling processes, etc. Simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings.

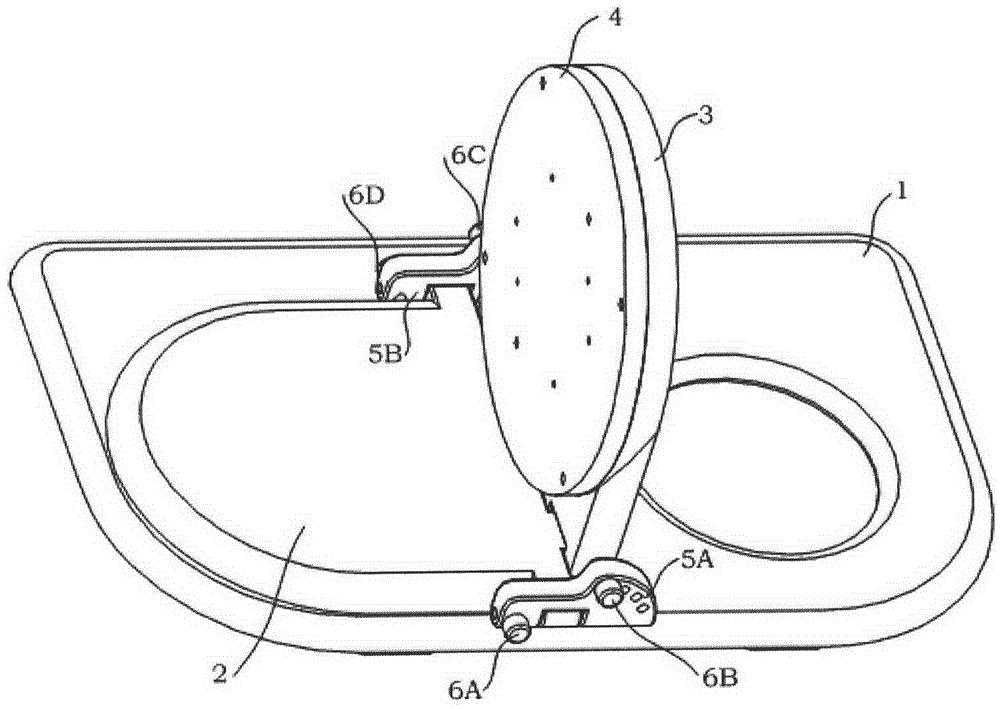

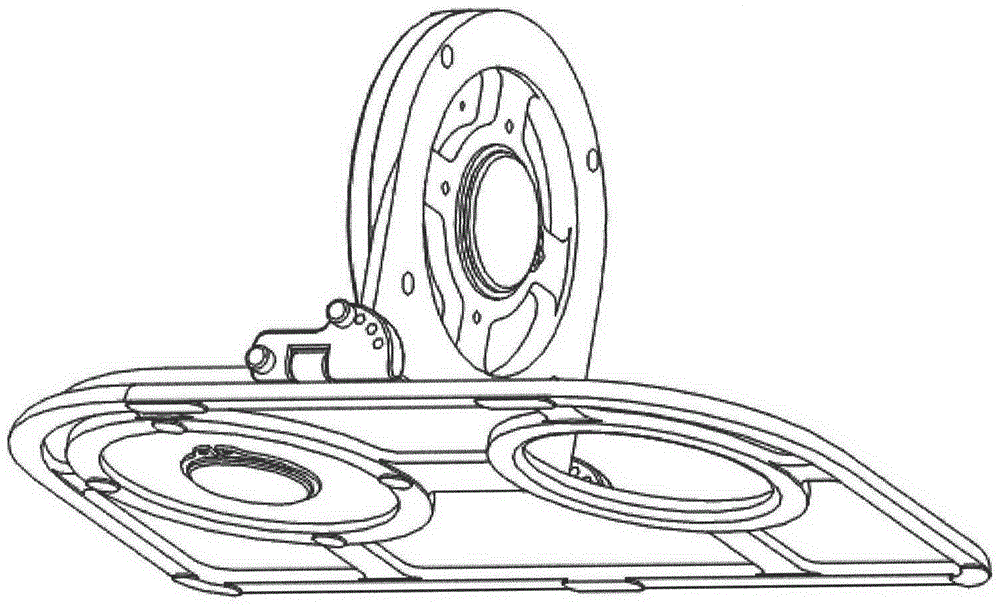

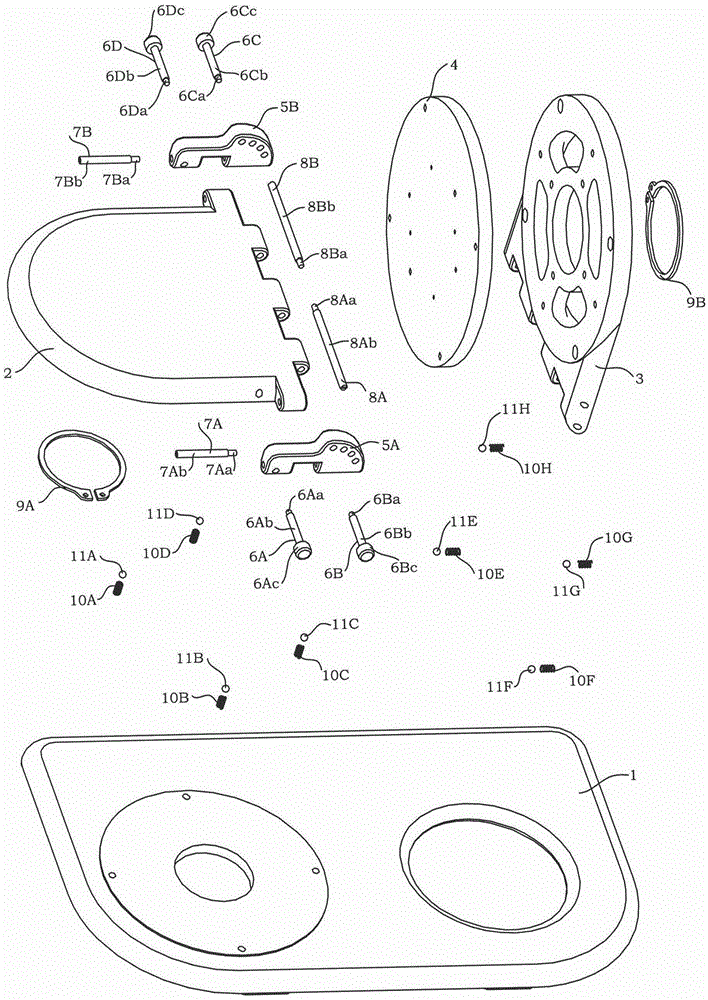

[0044] see Figure 1A , Figure 1B , Figure 1C As shown, a three-axis integrated fiber optic gyro optical path assembly auxiliary device includes a base 1, a horizontal rotating plate 2, a pitch rotating plate 3, an angle rotating plate 4, an A angle positioning block 5A, a B angle positioning block 5B, A Angle Positioning Shaft 6A, B Angle Positioning Shaft 6B, C Angle Positioning Shaft 6C, D Angle Positioning Shaft 6D, A Short Shaft 7A, B Short Shaft 7B, A Long Shaft 8A, B Long Shaft 8B, A Shaft Circlip 9A , circlip 9B for the B axis, the first pressure brake combination, and the second pressure brake combination; wherein, the first pressure brake combination consists of four compression springs 10A, 10B, 10C, 10D and four steel balls 11A, 11B, 11C, 11D, the second pressure brake combination is made up of four compression springs 10E, 10F, 10G, 10H and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com